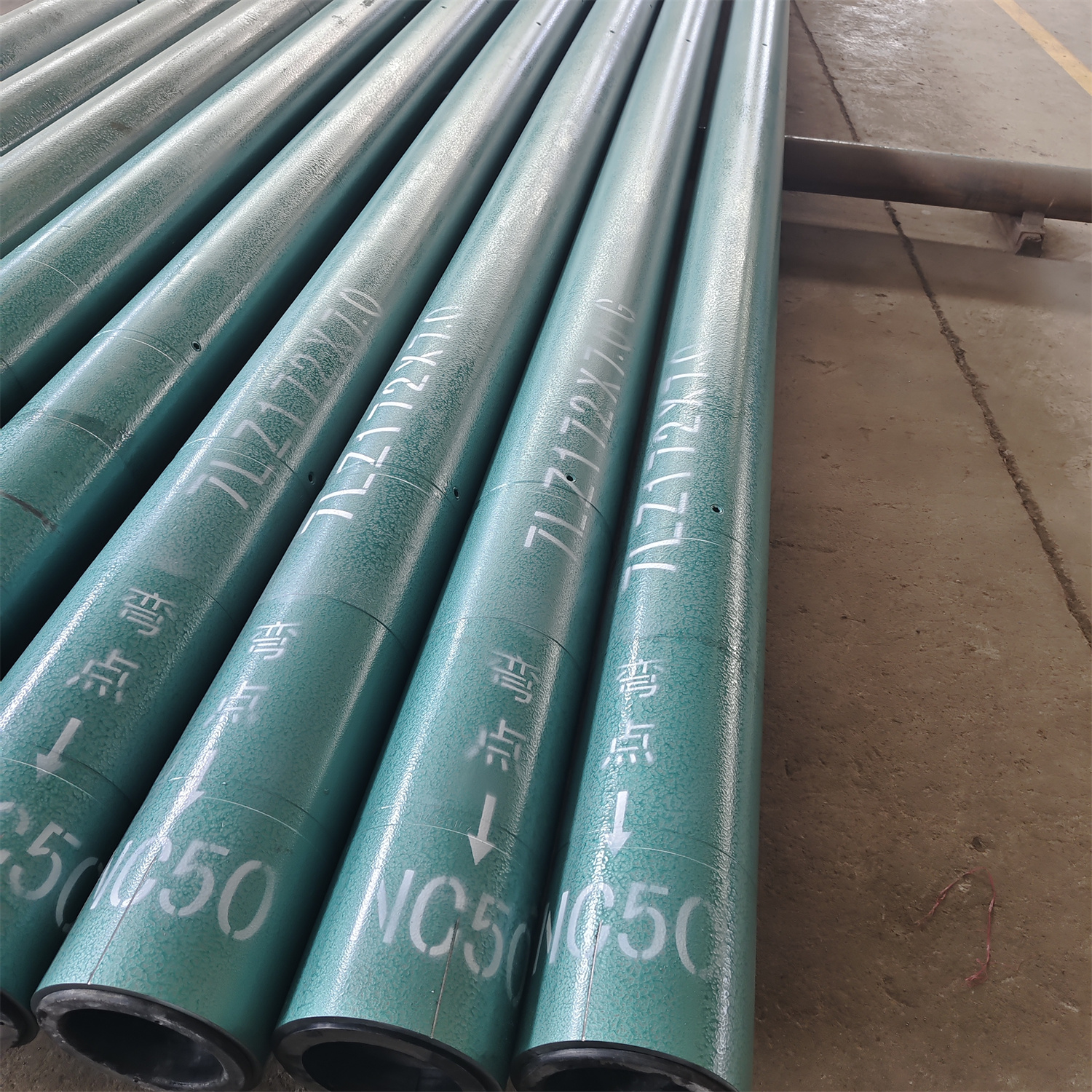

Product Introduction

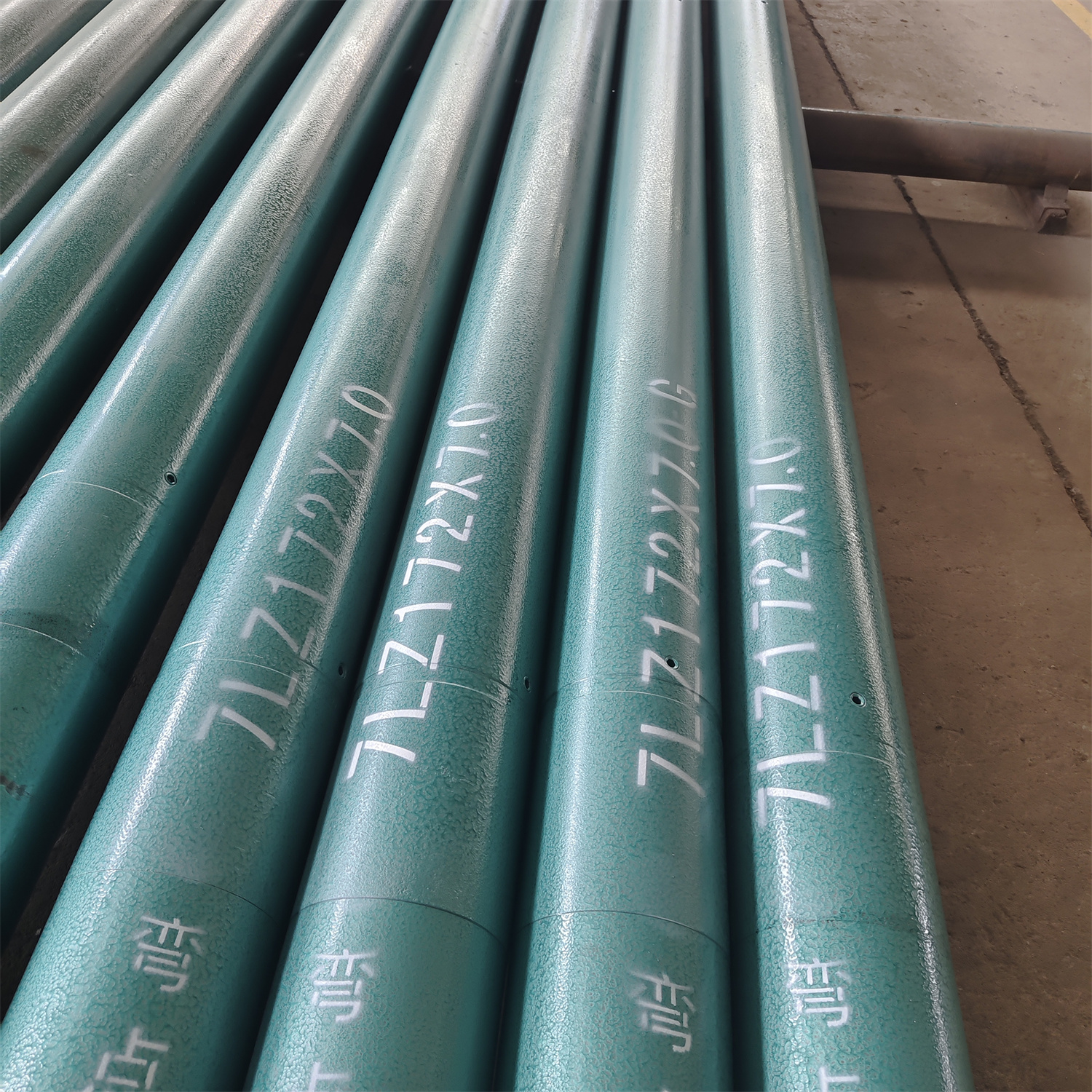

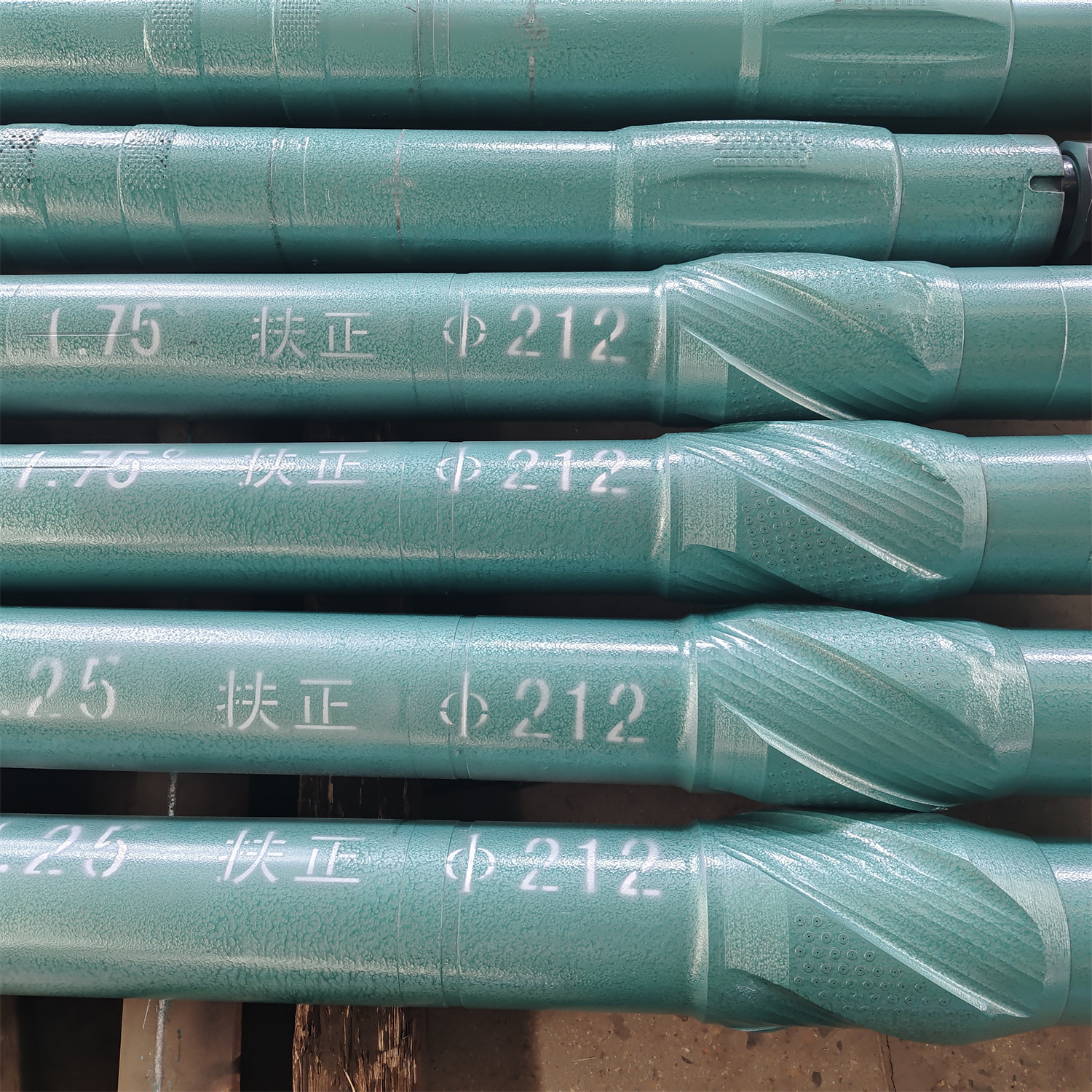

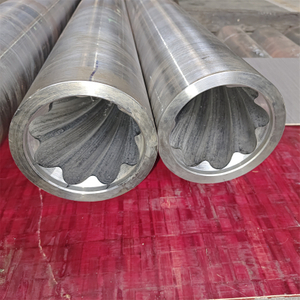

Introducing our Low Speed and High Torque Downhole Motor, a professional-grade tool designed to tackle the most challenging well conditions and deliver exceptional rock-breaking power.

With its intricate design, this motor is specifically engineered to handle complex well conditions, ensuring optimal performance even in the most demanding environments.

Equipped with a high torque capability, our downhole motor provides the necessary strength to effortlessly break through tough rock formations. Its powerful performance guarantees efficient drilling operations, saving both time and resources.

Trust our Low Speed and High Torque Downhole Motor to deliver the reliability and precision you need for successful drilling projects. Invest in this professional tool and experience unparalleled performance in the field.

Product Advantage

1. Using downhole motors that have a slow speed and strong twisting force can improve the speed and efficiency of drilling by providing more power to quickly penetrate formations.

2. Furthermore, employing downhole motors that have a slow speed and strong twisting force can reduce drilling costs, as well as lighten the load on drilling rigs and decrease energy usage.

3. The design of these downhole motors, which have a slow speed and strong twisting force, is relatively simple, easy to maintain, and very reliable, making them well-suited for drilling in various complex formations.

4. The downhole motor with a slow speed and strong twisting force has excellent control capabilities over the path of the wellbore, which is advantageous for improving the overall drilling quality.

Product Uses

1.Application Scenario: Drilling in Tough Formations Requiring Strong Rotational Force

Description: The Downhole Motor with Slow Speed and Strong Rotational Force is specially crafted to perform exceptionally well in drilling operations carried out in demanding geological formations known for their extreme hardness. These formations frequently present significant obstacles by resisting drilling tools, necessitating the use of specialized equipment to overcome these challenges. The downhole motor's outstanding torque capabilities enable effective penetration and progress through such formations, guaranteeing successful drilling operations in solid rock, cemented formations, or comparable tough environments.

2.Application Scenario: Challenging Drilling Situations with Different Well Conditions

Description: The Downhole Motor with Low Speed and High Torque is perfect for use in wells that have many difficult conditions. These conditions could include drilling in different directions, drilling over long distances, drilling horizontally, or drilling through unstable formations. The downhole motor can consistently produce high torque, which allows for precise control and maneuverability. This helps operators navigate through complicated well paths and overcome obstacles successfully. The motor's dependable performance ensures that drilling progresses smoothly and reduces the chances of delays or equipment problems.

3. Application Scenario: High Torque Demands for Efficient Drilling Operations

Description: The Low Speed and High Torque Downhole Motor is specifically engineered to meet the requirements of drilling operations that demand substantial torque output. In applications where conventional drilling methods may prove insufficient, such as drilling large-diameter boreholes, reaming, or milling operations, this downhole motor excels. Its high torque capabilities enable efficient and effective drilling, ensuring rapid progress and reduced drilling time. By providing the necessary power and torque, the downhole motor enhances drilling efficiency and productivity, ultimately resulting in cost savings and improved overall operational performance.

Certifications

We have effectively obtained certifications for API Q1 and API 7-1 systems, in addition to ISO9001 for managing quality, ISO14001 for managing the environment, ISO45001 for managing occupational health, measurement management, intellectual property management, and managing green enterprises.

FAQ

1. What is a Low Speed and High Torque Downhole Motor?

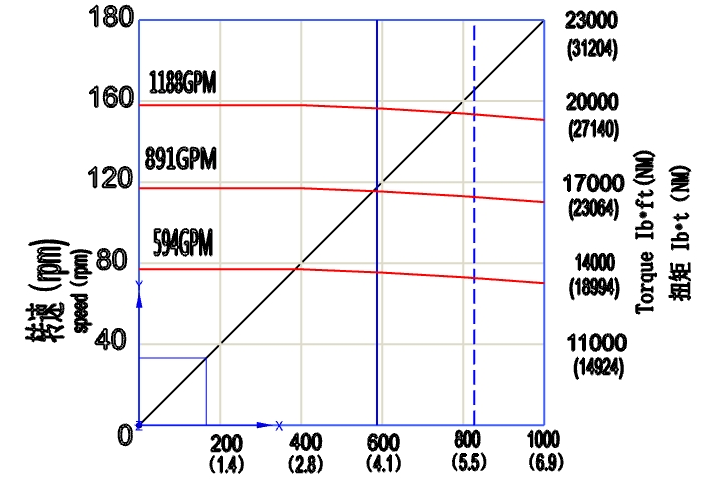

- A Low Speed and High Torque Downhole Motor is a specialized tool used in the oil and gas industry for drilling and wellbore operations. It provides the necessary power and torque to rotate the drill bit at a controlled speed while drilling underground.

2. How does a Low Speed and High Torque Downhole Motor work?

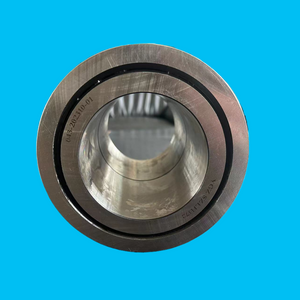

- The Low Speed and High Torque Downhole Motor operates by converting hydraulic pressure into mechanical energy. The hydraulic fluid flows through the motor, creating rotational force that is transmitted to the drill bit, allowing it to penetrate the earth's surface.

3. What are the advantages of using a Low Speed and High Torque Downhole Motor?

- The main advantage of using a Low Speed and High Torque Downhole Motor is its ability to deliver high torque at low rotational speeds. This allows for improved drilling efficiency, reduced wear on the drill bit, and enhanced control over the drilling process.

4. How does the quality of the Low Speed and High Torque Downhole Motor ensure reliable performance?

- The quality of the Low Speed and High Torque Downhole Motor is ensured through a comprehensive certification system. Our product undergoes rigorous testing and meets industry standards to guarantee its reliability, durability, and performance in demanding downhole conditions.

5. What sets our Low Speed and High Torque Downhole Motor apart from competitors?

- Our Low Speed and High Torque Downhole Motor stands out from competitors due to its superior design, precision engineering, and advanced manufacturing techniques. It is built to withstand harsh environments, deliver exceptional performance, and provide long-lasting reliability for efficient drilling operations.