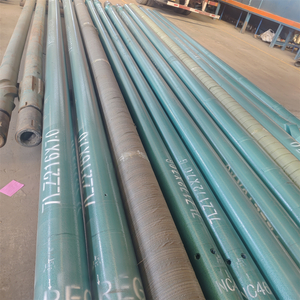

Product Introduction

The saltwater mud Downhole motor assembly is a volumetric motor that converts the hydraulic energy of high-pressure drilling fluid into mechanical energy, and drives the spindle and drill bit to rotate through the rotor to achieve the purpose of drilling the drill bit. Drilling fluid is usually mud containing salt based ions, and the rotor adopts tungsten carbide spraying technology, which can effectively prevent mud corrosion.

Product Advantage

1. Having over thirty years of experience, we specialize in producing Downhole motors.

2. Our factory is outfitted with advanced manufacturing equipment like CNC spiral milling machines and 1000 ton injection molding presses.

3. We provide a range of rubber formulations, including standard, oil-resistant, and high-temperature choices.

4. Our rotors are treated with anti-corrosion coatings such as chromium plating, salt-resistant tungsten carbide, and nickel plating.

5. The thread connections on our items can be customized to suit the individual requirements of our clients.

Product Uses

The saltwater mud motor is mainly used in downhole motors. In deep wells with hard rock layers, the bottom hole pressure is high. At this time, the drilling fluid is usually saltwater mud containing chloride ions, which is used to neutralize the pressure and achieve the goal of preventing the drilling fluid from leaking out.

FAQ

1. What is a Saturated Brine Mud Downhole Motor Assembly used for?

- A Saturated Brine Mud Downhole Motor Assembly is used in drilling operations to provide power and torque for drilling tools in challenging environments.

2. How does the quality of your Downhole Motor Assembly compare to others in the market?

- Our Downhole Motor Assembly is manufactured to the highest standards in our factory, ensuring superior quality and reliability for your drilling operations.

3. What factors determine the price of a Saturated Brine Mud Downhole Motor Assembly?

- The price of our Saturated Brine Mud Downhole Motor Assembly is determined by factors such as the specifications, features, and quantity required for your project.

4. What is the typical lead time for delivery of a Downhole Motor Assembly?

- Our standard lead time for delivery of a Downhole Motor Assembly is determined by the complexity of the order and current demand, but we strive to provide fast and efficient service to meet your project deadlines.

5. Can you provide a product catalog for your Downhole Motor Assembly?

- Yes, we offer a comprehensive product catalog detailing the specifications and options available for our Downhole Motor Assembly. Please contact us for more information.