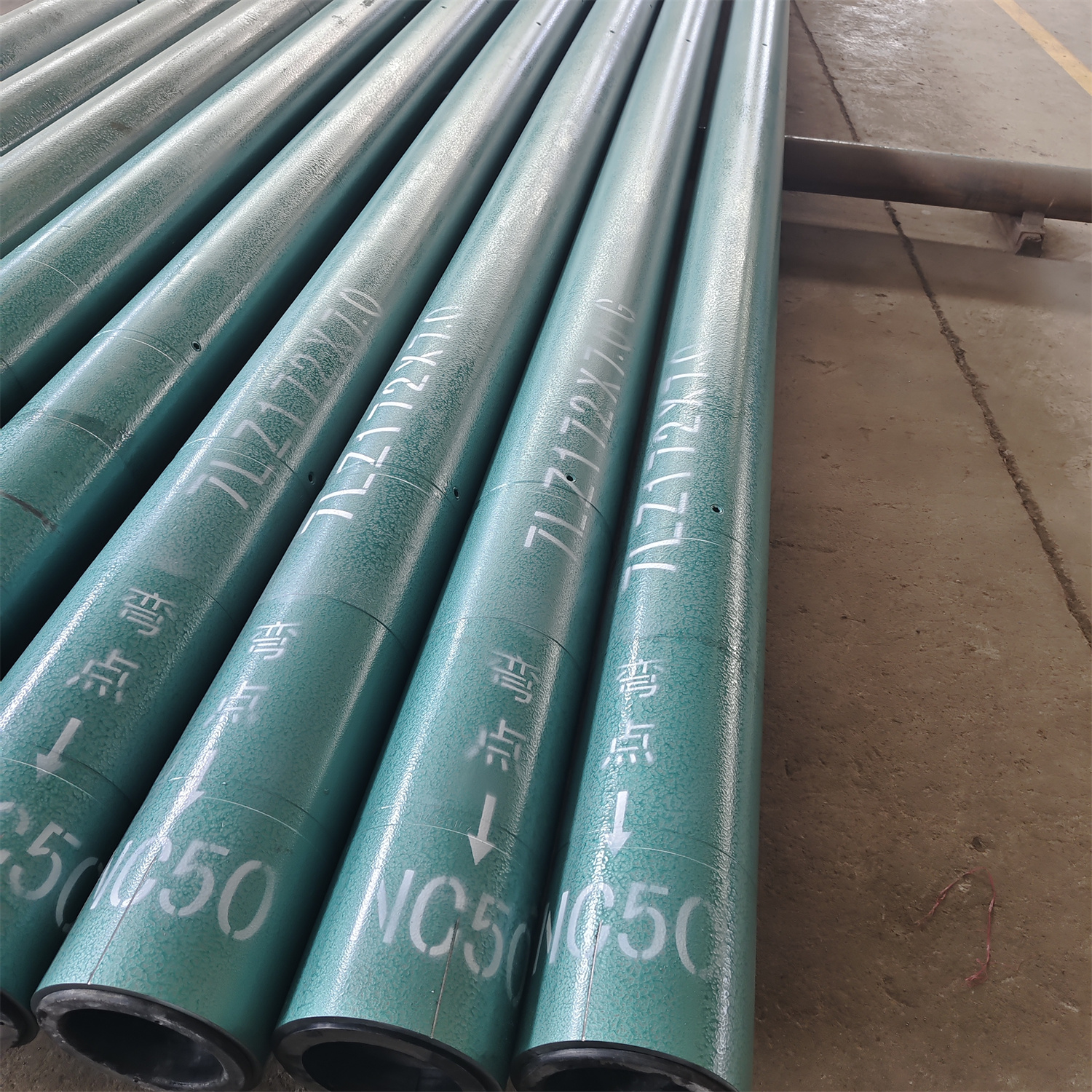

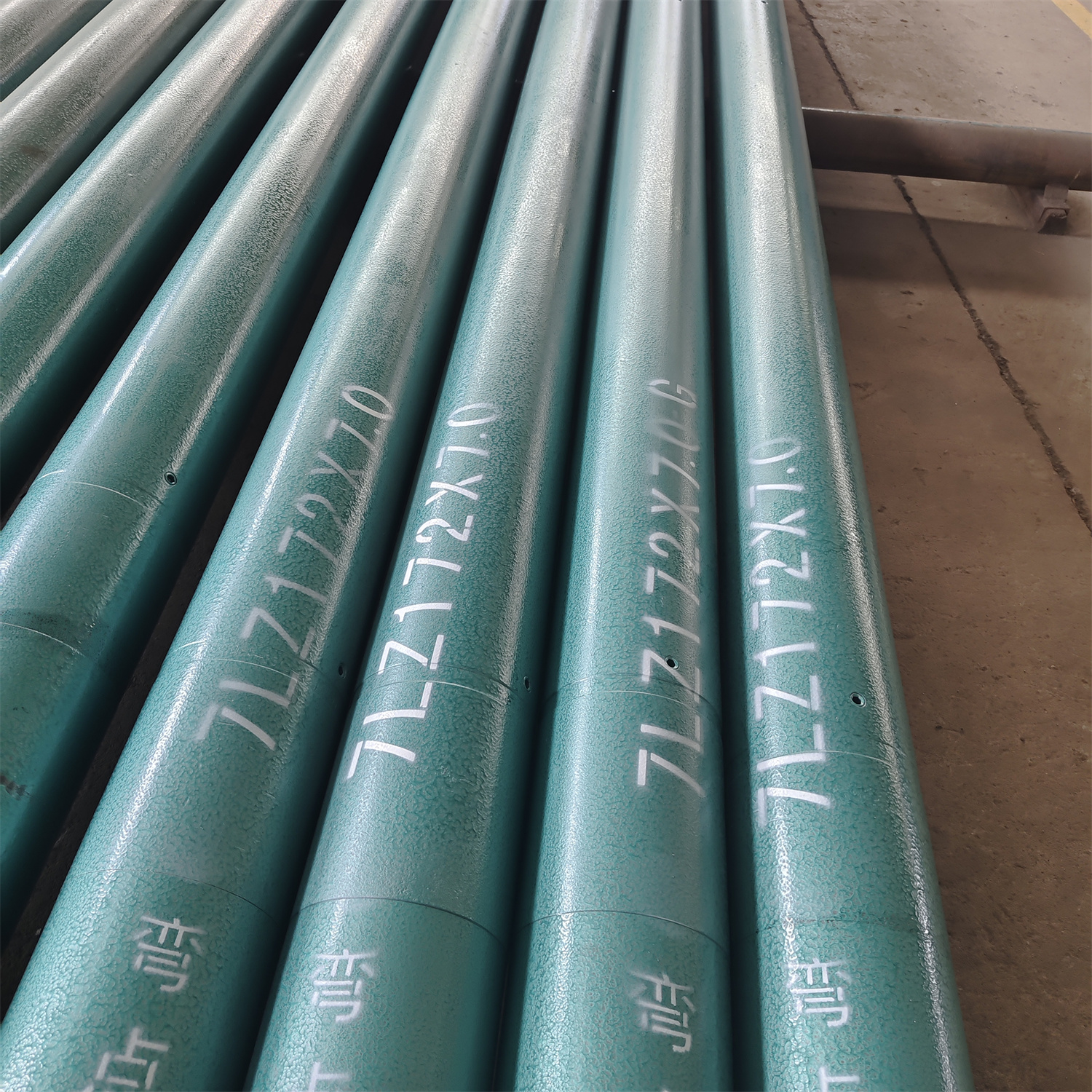

Product Introduction

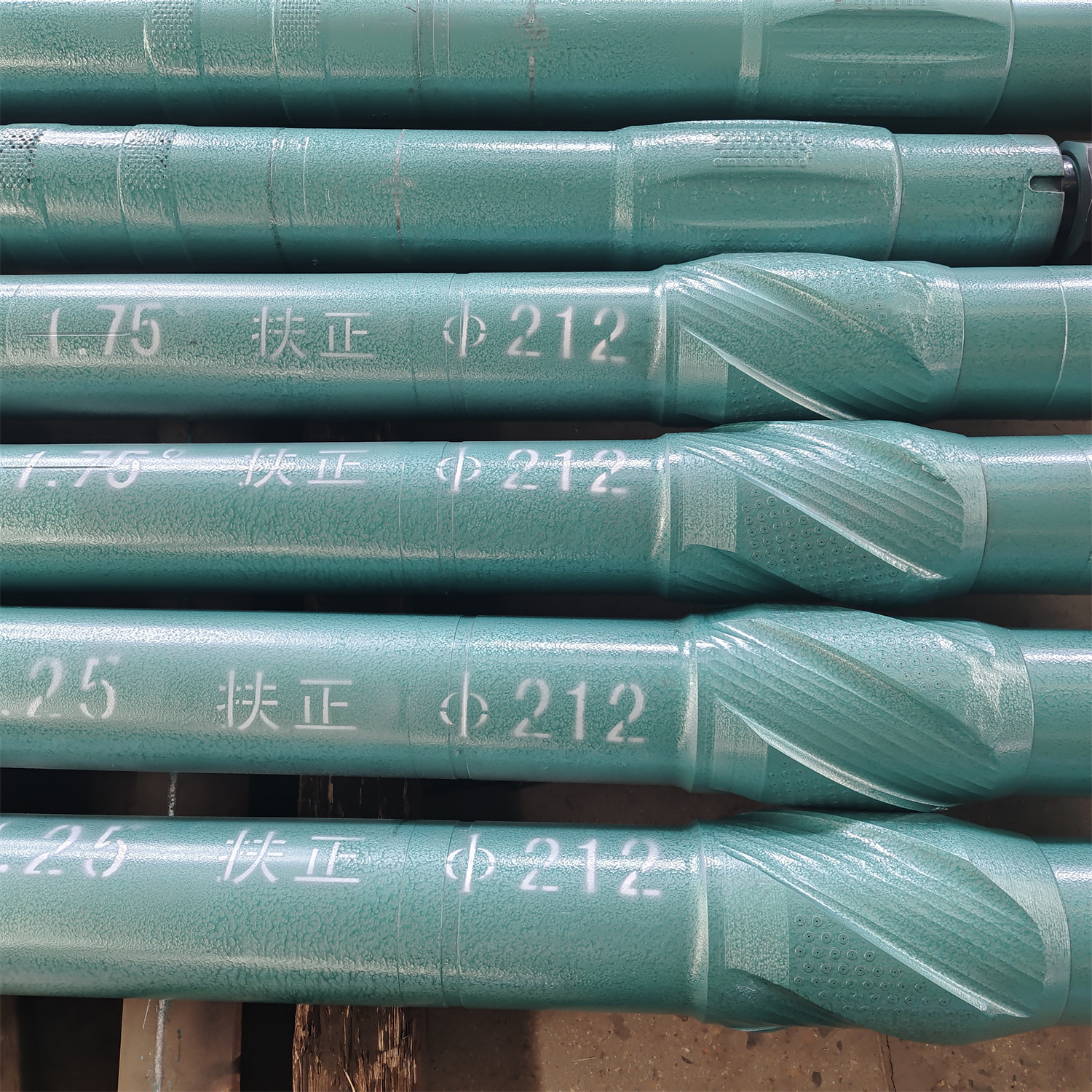

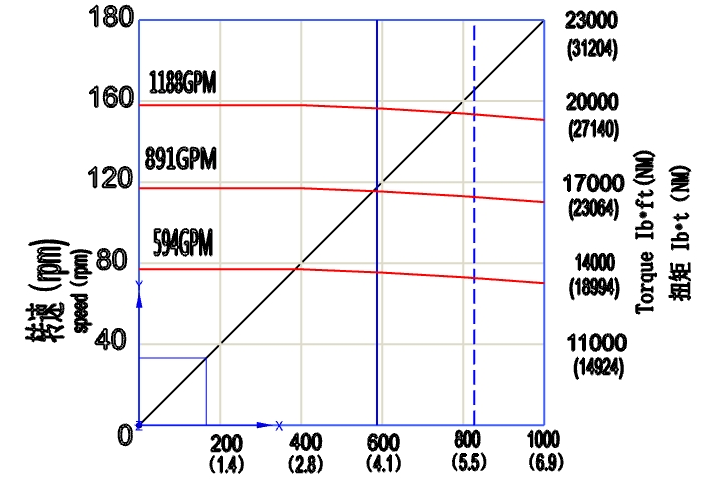

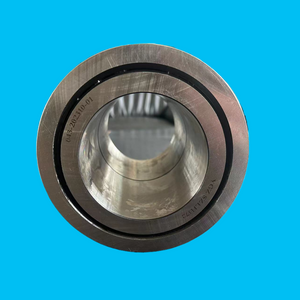

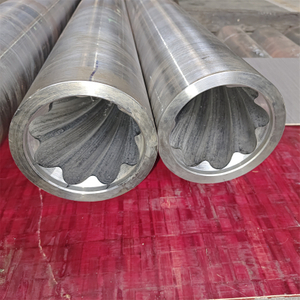

The Downhole Power Drilling Tool, known as the Positive Displacement motor (PDM), is a type of motor that operates using drilling fluid. Its function is as follows: as the mud pump pumps mud flow into the motor through the bypass valve, a pressure difference is created between the motor's inlet and outlet. This pressure difference causes the rotor to rotate around the stator's axis, transferring the rotational speed and torque to the drilling bit through the cardan shaft and transmission shaft. This allows for the drilling operation to take place.

Product Advantage

The Positive Displacement motor is a drilling tool that is powered by drilling fluid and used in downhole operations. It offers several advantages:

- Maintains original borehole size: Unlike other motors, the downhole motor drills a borehole of the same size as the original one, eliminating the need for further enlargement.

- Can drill through bridging plugs: In situations where there are bridging plugs in the well, the downhole motor can easily drill through them and ensure a clean circulation at the bottom of the well before initiating the incline.

- Minimal speed variation: Compared to turbines, the downhole motor experiences only a small difference in speed between idling and working conditions. This characteristic is beneficial when selecting drill bits.

Product Uses

sitive displacement motors that are commonly used in various drilling scenarios. These scenarios include:

1. Directional well sloping section: When dealing with stable formations, regular boreholes, and low sloping rates, downhole motors can effectively control the trajectory of the borehole.

2. Horizontal section: Downhole motors are particularly useful for drilling horizontal sections, especially when dealing with long horizontal sections and large borehole sizes. They can greatly enhance drilling efficiency and the overall quality of the drilling process.

3. Underbalanced drilling: Downhole motors are also suitable for underbalanced drilling, especially when dealing with small borehole sizes. They can significantly improve drilling efficiency and the quality of the drilling operation.

4. Small borehole drilling: Downhole motors are well-suited for drilling small boreholes, especially when dealing with limited space. They can greatly enhance drilling efficiency and the overall quality of the drilling process.

5. Deep borehole drilling: Downhole motors are effective for drilling deep boreholes, especially when dealing with small borehole sizes. Screw drilling tools can greatly improve drilling efficiency and the overall quality of the drilling operation.

In summary, screw drilling tools are efficient, reliable, and versatile downhole motors that are commonly used in a variety of drilling scenarios.

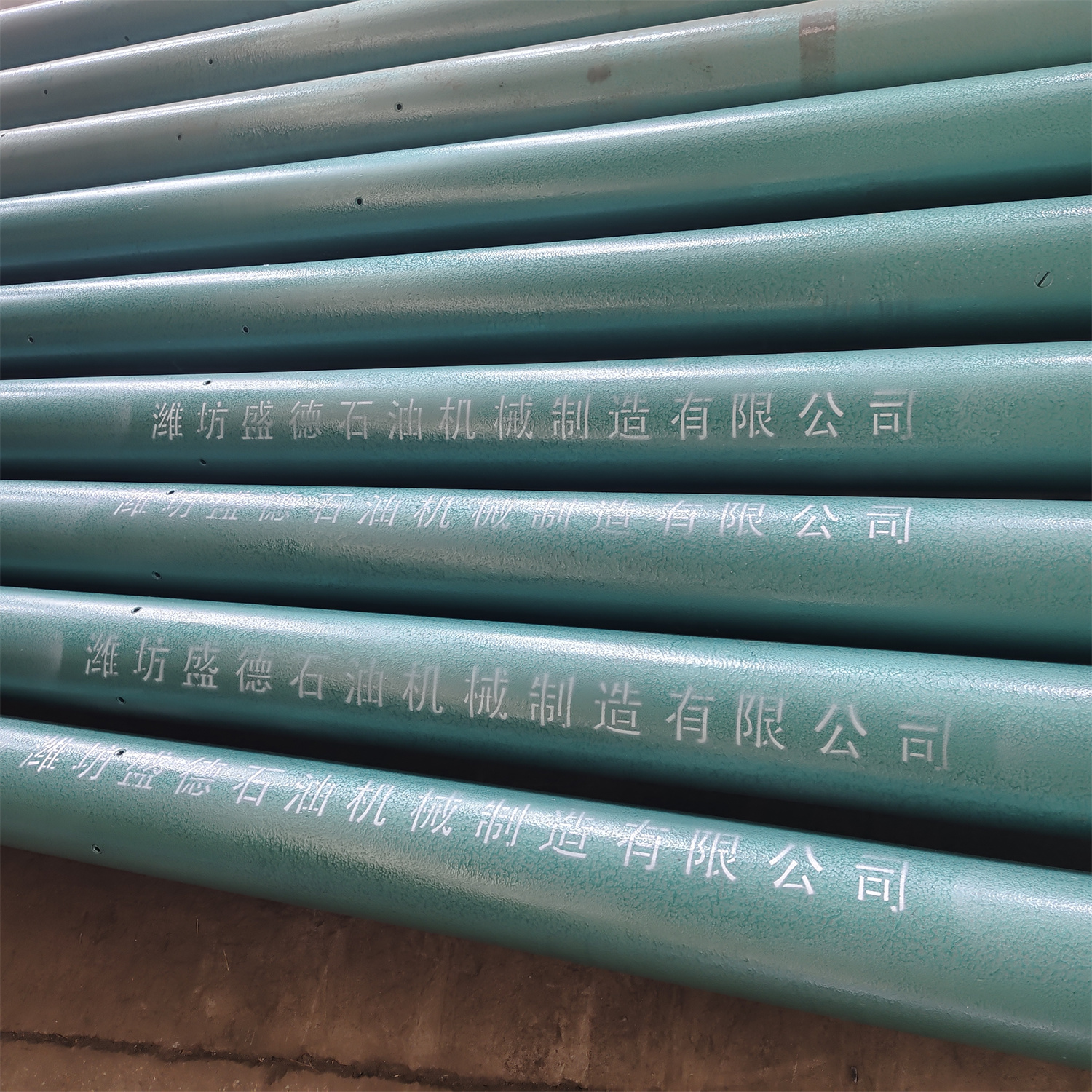

Certifications

We have successfully acquired certifications for API Q1 and API 7-1 systems, along with ISO9001 for quality management, ISO14001 for environmental management, ISO45001 for occupational health management, measurement management, intellectual property management, and green enterprise management.

FAQ

1. What is a PDM Downhole Mud Motor?

- A PDM Downhole Mud Motor is a type of downhole motor used in drilling operations to provide rotational power to the drill bit.

2. How does a PDM Downhole Mud Motor work?

- A PDM Downhole Mud Motor operates by using the flow of drilling mud to drive a rotor, which in turn rotates the drill bit.

3. What are the advantages of using a PDM Downhole Mud Motor?

- Some advantages of using a PDM Downhole Mud Motor include increased drilling efficiency, improved control over drilling operations, and reduced wear on the drill bit.

4. Does the PDM Downhole Mud Motor comply with any specific industry standards?

- Yes, the PDM Downhole Mud Motor is designed and manufactured to meet industry standards and specifications, ensuring its reliability and performance.

5. Is the PDM Downhole Mud Motor certified by any recognized certification bodies?

- Yes, the PDM Downhole Mud Motor undergoes rigorous testing and certification by recognized bodies to ensure its compliance with industry standards and regulations.