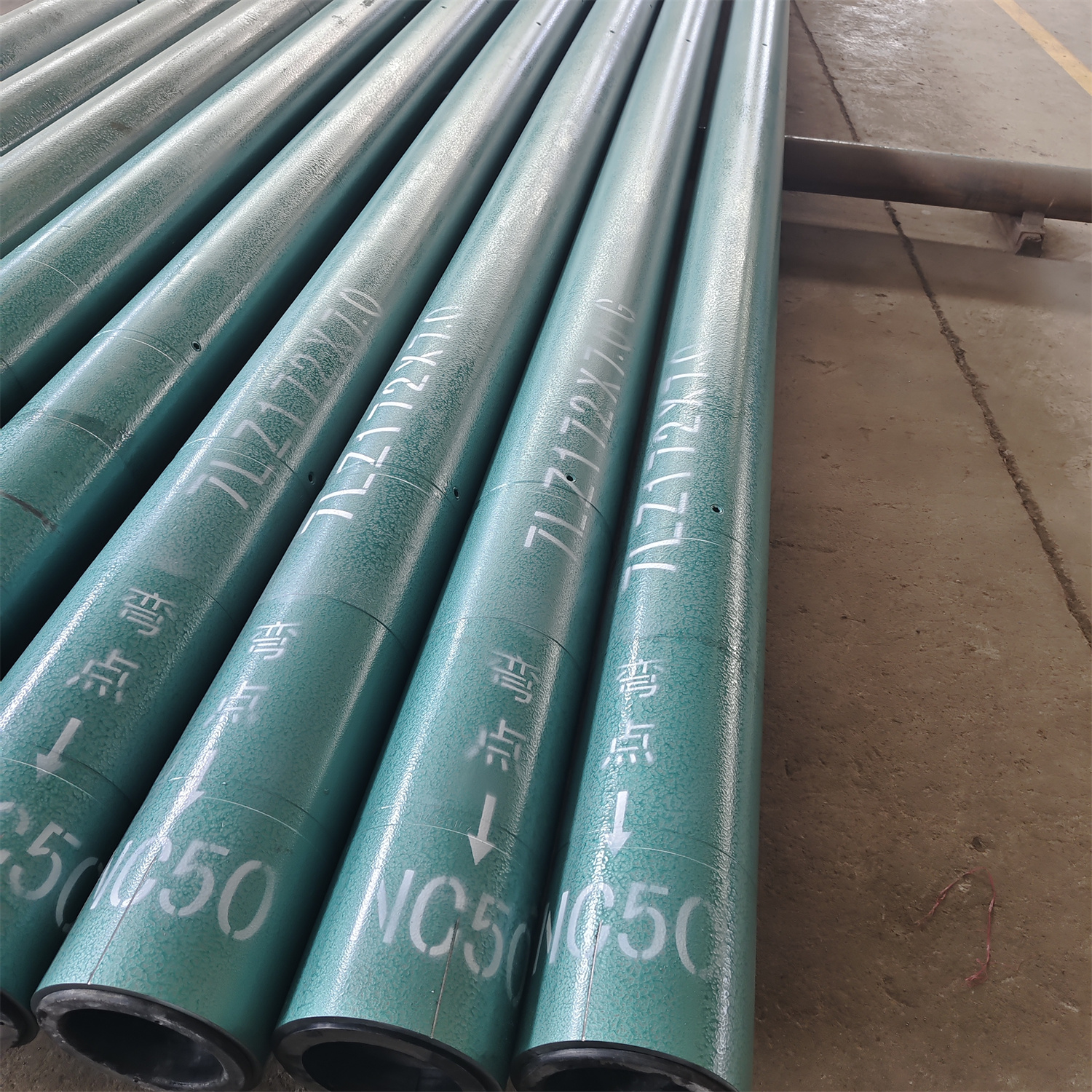

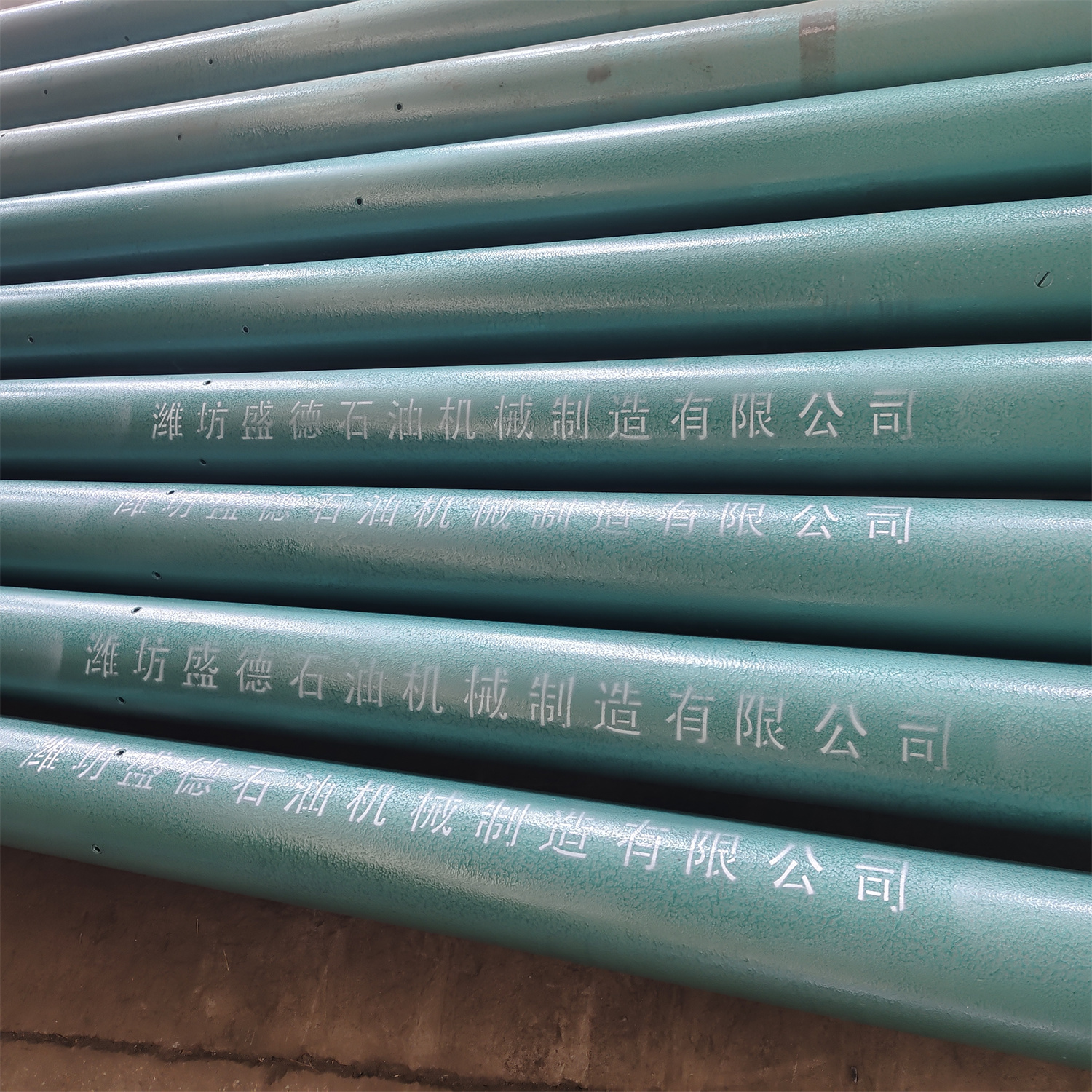

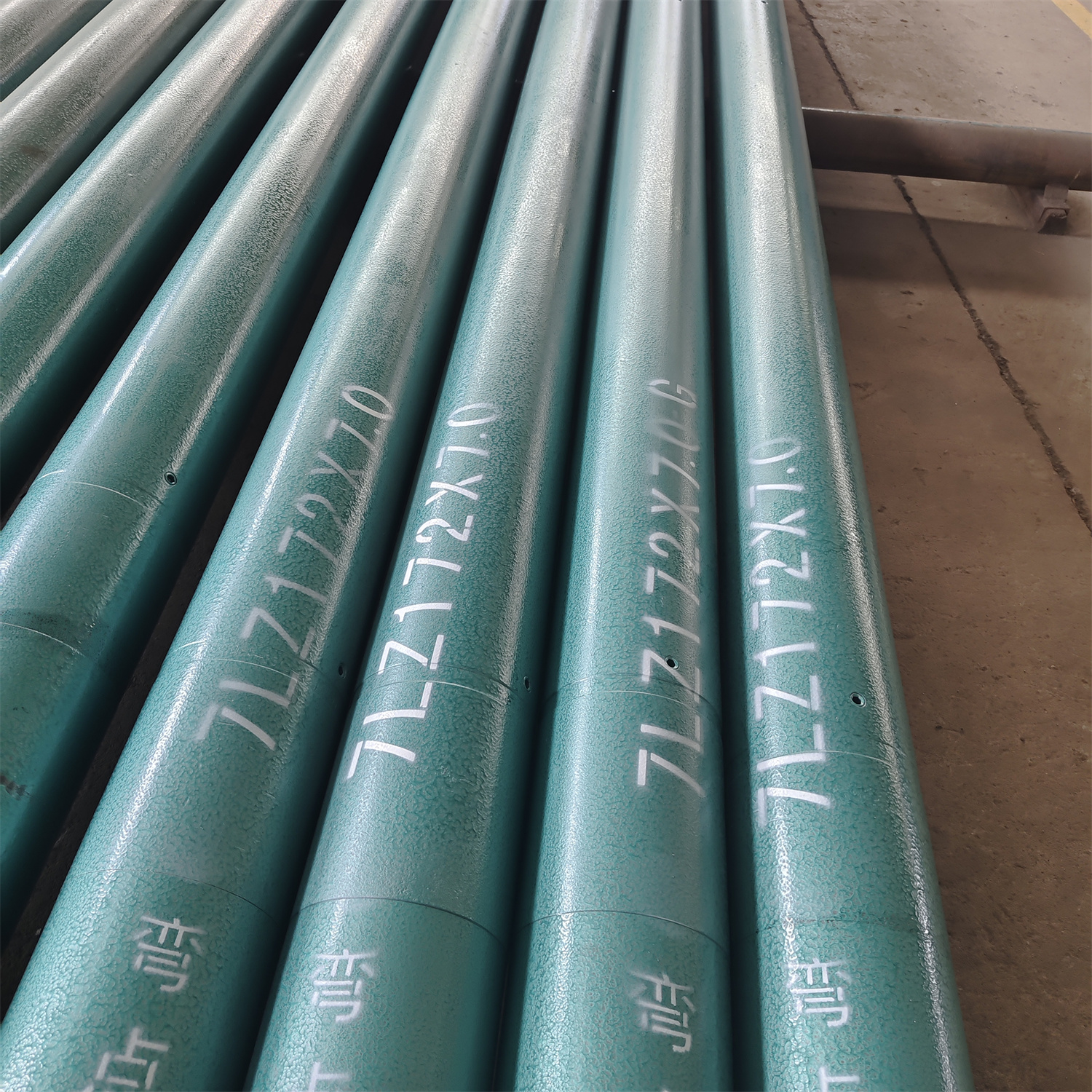

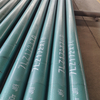

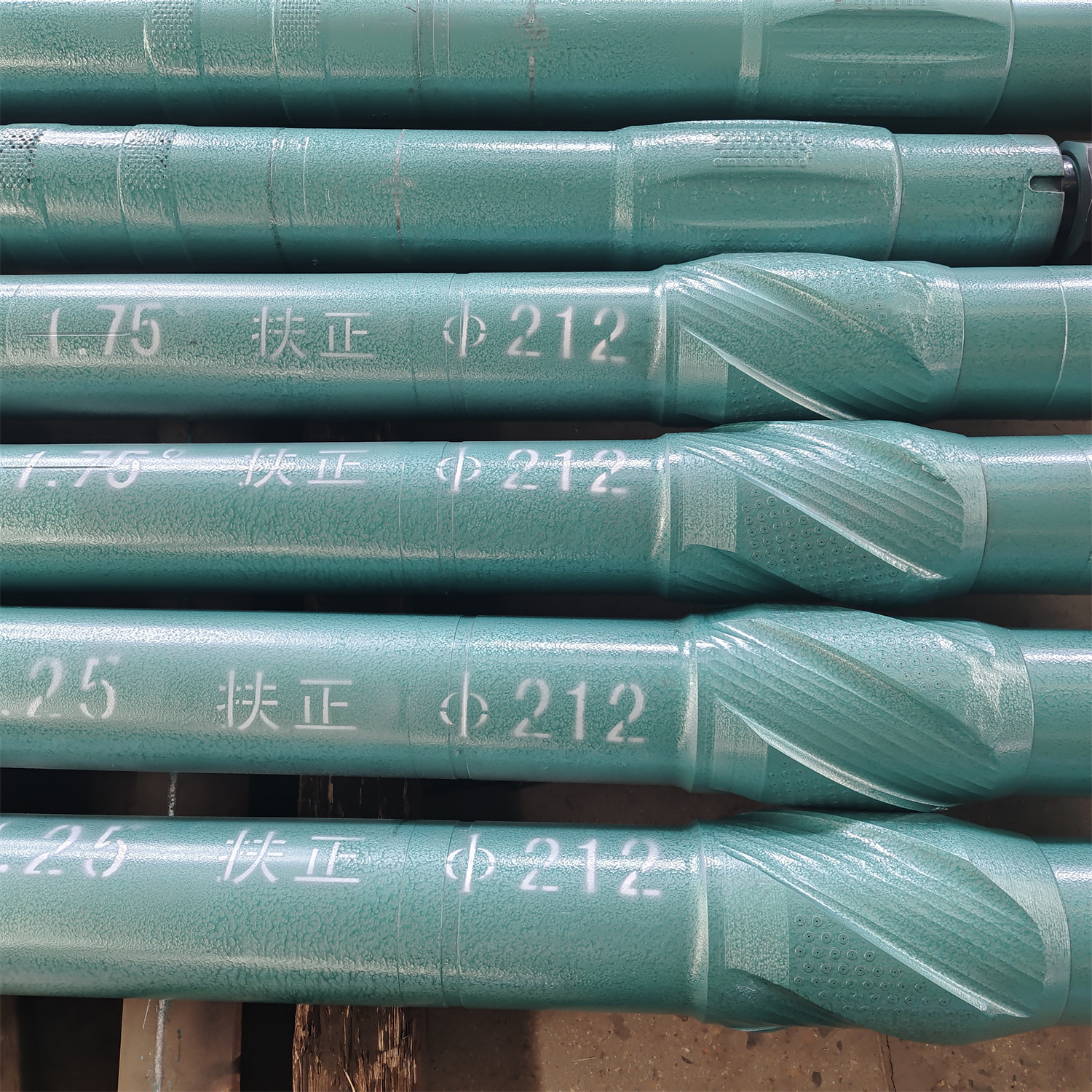

Product Introduction

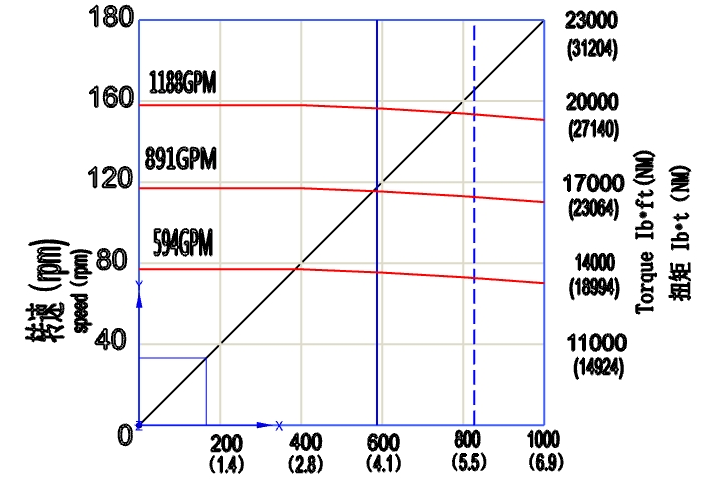

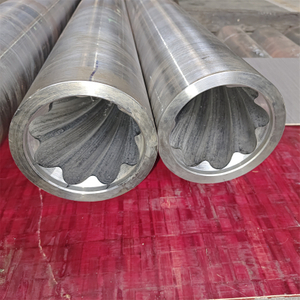

Introducing our Low Speed and High Torque Downhole Motor, designed for tackling complex well conditions and delivering exceptional performance. With its low rotational speed and impressive torque, this motor provides the power output you need to overcome challenging drilling environments.

Built with precision engineering and advanced technology, our downhole motor is specifically designed to excel in demanding drilling operations. Its low speed capability allows for enhanced control and maneuverability, ensuring optimal performance even in the most intricate well conditions.

The high torque generated by our downhole motor enables efficient drilling, allowing you to achieve greater power output. This increased torque translates into improved drilling efficiency, reduced drilling time, and ultimately, cost savings for your operations.

Our Low Speed and High Torque Downhole Motor is the ideal choice for operators seeking a reliable and high-performing solution for complex well conditions. Its professional-grade design ensures durability and longevity, making it a valuable investment for your drilling projects.

Experience the power and efficiency of our Low Speed and High Torque Downhole Motor and take your drilling operations to new heights. Trust in our product's exceptional performance and professional-grade quality to deliver the results you need in even the most challenging drilling environments.

Product Advantage

1. Low speed and high torque downhole motors can improve drilling speed and efficiency, as they can provide greater torque to help quickly drill into formations

2. Low speed and high torque downhole motors can also reduce drilling costs, and their use can reduce drilling rig load and energy consumption

3. The structure of the low-speed and high torque downhole motor is relatively simple, easy to maintain, and has high reliability, making it suitable for drilling operations in various complex formations.

4. The low-speed and high torque downhole motor has strong control ability over wellbore trajectory, which is beneficial for improving drilling quality

Product Uses

1. Application Scenario: Drilling in Hard Formations with High Torque Requirements

Description: The Low Speed and High Torque Downhole Motor is specifically designed to excel in drilling operations conducted in challenging geological formations characterized by extreme hardness. These formations often pose significant difficulties due to their resistance to drilling tools and require specialized equipment to overcome these challenges. The downhole motor's exceptional torque capabilities enable efficient penetration and advancement through such formations, ensuring successful drilling operations in hard rock, cemented formations, or other similarly challenging environments.

2. Application Scenario: Complex Well Conditions with Varying Drilling Challenges

Description: The Low Speed and High Torque Downhole Motor is highly suitable for deployment in wells that present a multitude of complex conditions, requiring adaptability and robust performance. These conditions may include directional drilling, extended reach drilling, horizontal drilling, or drilling through unstable formations. The downhole motor's ability to provide consistent high torque output allows for precise control and maneuverability, enabling operators to navigate through intricate well paths and overcome obstacles effectively. Its reliable performance ensures optimal drilling progress and minimizes the risk of operational delays or equipment failures.

3. Application Scenario: High Torque Demands for Efficient Drilling Operations

Description: The Low Speed and High Torque Downhole Motor is specifically engineered to meet the requirements of drilling operations that demand substantial torque output. In applications where conventional drilling methods may prove insufficient, such as drilling large-diameter boreholes, reaming, or milling operations, this downhole motor excels. Its high torque capabilities enable efficient and effective drilling, ensuring rapid progress and reduced drilling time. By providing the necessary power and torque, the downhole motor enhances drilling efficiency and productivity, ultimately resulting in cost savings and improved overall operational performance.

4. Application Scenario: Drilling in Extreme Conditions and Hostile Environments

Description: The Low Speed and High Torque Downhole Motor is designed to withstand and excel in extreme drilling conditions and hostile environments. These scenarios may include drilling in high-temperature formations, high-pressure environments, or corrosive drilling fluids. The downhole motor's robust construction and advanced materials ensure reliable performance and longevity under such challenging circumstances. Its ability to deliver high torque even in harsh environments allows operators to maintain drilling progress and achieve successful outcomes, minimizing downtime and maximizing operational efficiency.

5. Application Scenario: Enhanced Drilling Performance in Offshore Operations

Description: The Low Speed and High Torque Downhole Motor finds extensive application in offshore drilling operations, where the demands for efficient and reliable drilling are paramount. Offshore drilling often involves complex geological formations, challenging well profiles, and strict operational timelines. The downhole motor's high torque capabilities enable efficient drilling progress, ensuring timely completion of offshore projects. Its ability to overcome challenging conditions, such as drilling through salt formations or encountering high-pressure zones, enhances operational safety and success, making it an ideal choice for offshore drilling applications.

Note: The product name, "Low Speed and High Torque Downhole Motor," and its function, "坚硬地层,复杂井况,大扭矩," have been incorporated into the descriptions while adhering to the professional tone and English-US language requirements.

Certifications

We have successfully acquired certifications for API Q1 and API 7-1 systems, along with ISO9001 for quality management, ISO14001 for environmental management, ISO45001 for occupational health management, measurement management, intellectual property management, and green enterprise management.

FAQ

1. What is a downhole motor and how does it work?

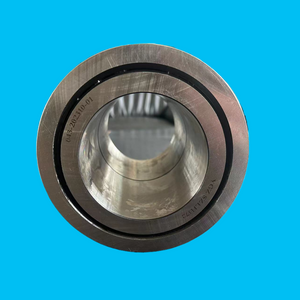

A downhole motor is a type of drilling tool used in the oil and gas industry. It is designed to provide low speed and high torque to rotate the drill bit, allowing for efficient drilling operations. The motor uses hydraulic power to convert fluid pressure into mechanical energy, which is then transmitted to the drill bit.

2. What are the advantages of using a low speed and high torque downhole motor?

The low speed and high torque capabilities of a downhole motor offer several advantages. Firstly, it allows for improved control and precision during drilling operations. Secondly, it enables the motor to overcome challenging geological formations, such as hard rock or high-pressure zones. Additionally, the high torque reduces the risk of drill bit stalling, enhancing overall drilling efficiency.

3. How does the delivery time of the low speed and high torque downhole motor impact project timelines?

The delivery time of the downhole motor is a crucial factor in project planning. Timely delivery ensures that drilling operations can proceed as scheduled, minimizing downtime and associated costs. It is important to communicate delivery expectations with the supplier to align project timelines and avoid any potential delays.

4. How does the low speed and high torque downhole motor handle different formation conditions?

The low speed and high torque capabilities of the downhole motor make it suitable for various formation conditions. Whether drilling through soft sedimentary layers or hard rock formations, the motor's torque allows it to efficiently penetrate and navigate different geological formations. However, it is essential to consider the specific motor specifications and consult with experts to ensure optimal performance in specific formation conditions.

5. How does the low speed and high torque downhole motor ensure quality and reliability?

The low speed and high torque downhole motor undergoes rigorous quality control measures to ensure its reliability. This includes comprehensive testing and inspection during the manufacturing process to meet industry standards. Additionally, regular maintenance and servicing are recommended to extend the motor's lifespan and maintain its performance.