Product Introduction

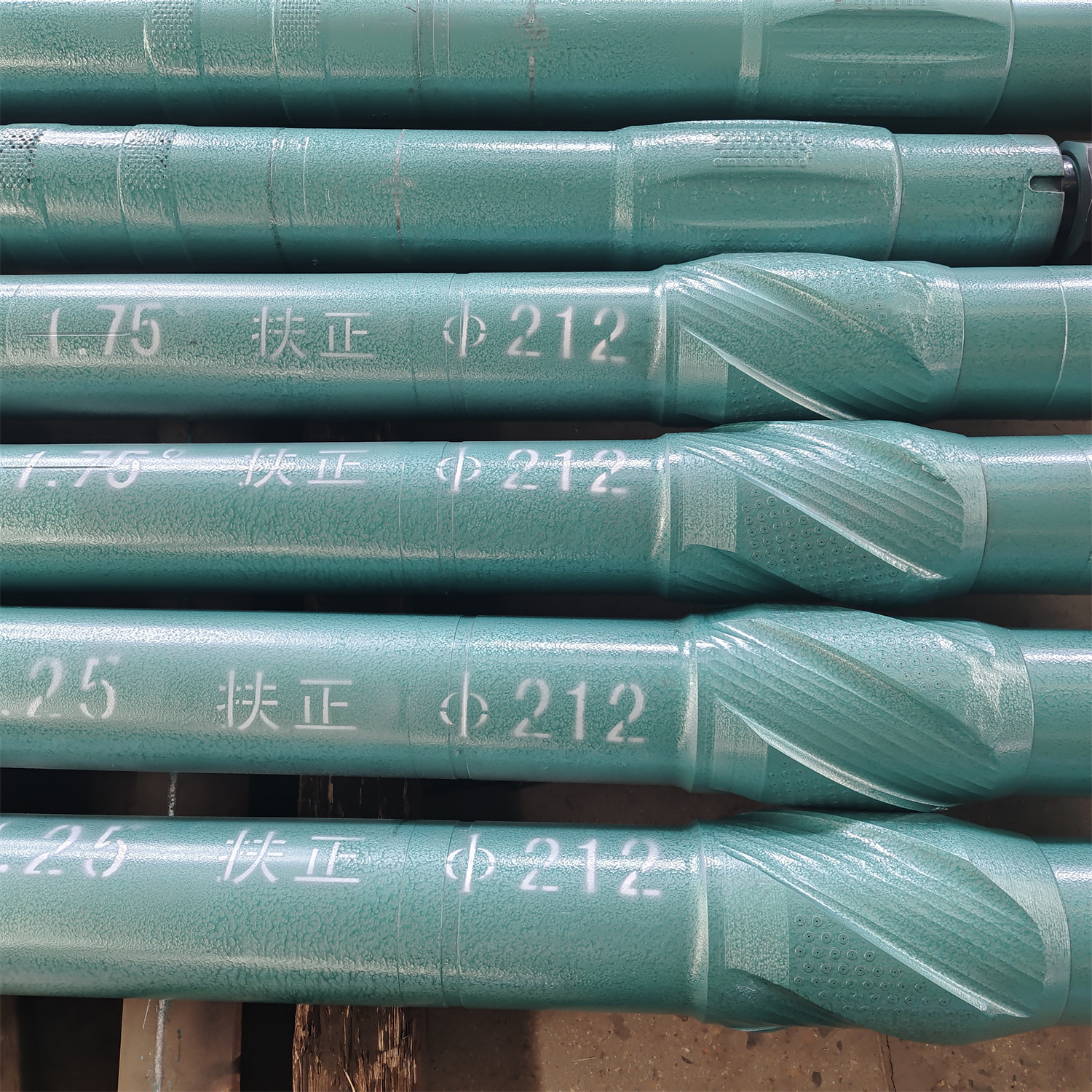

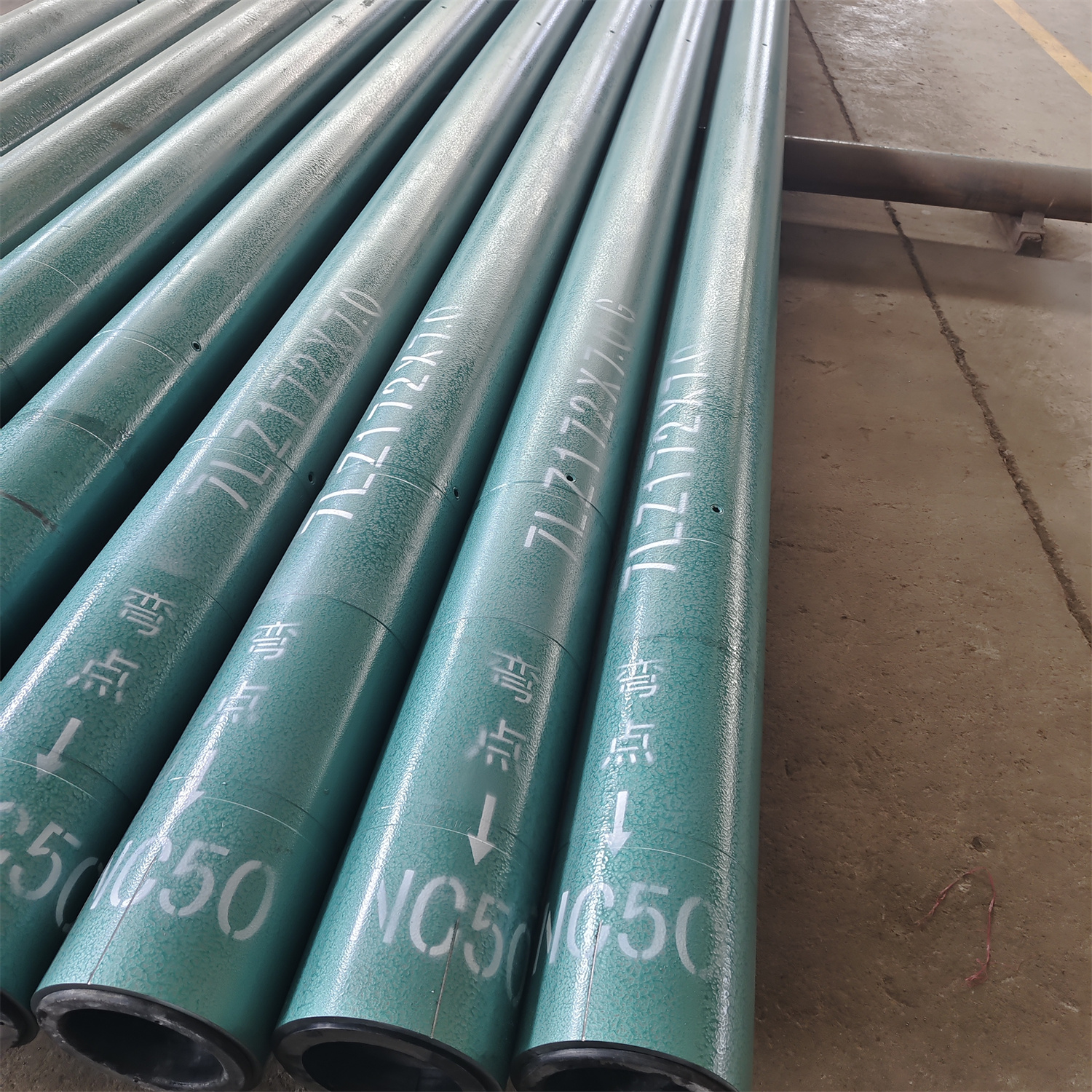

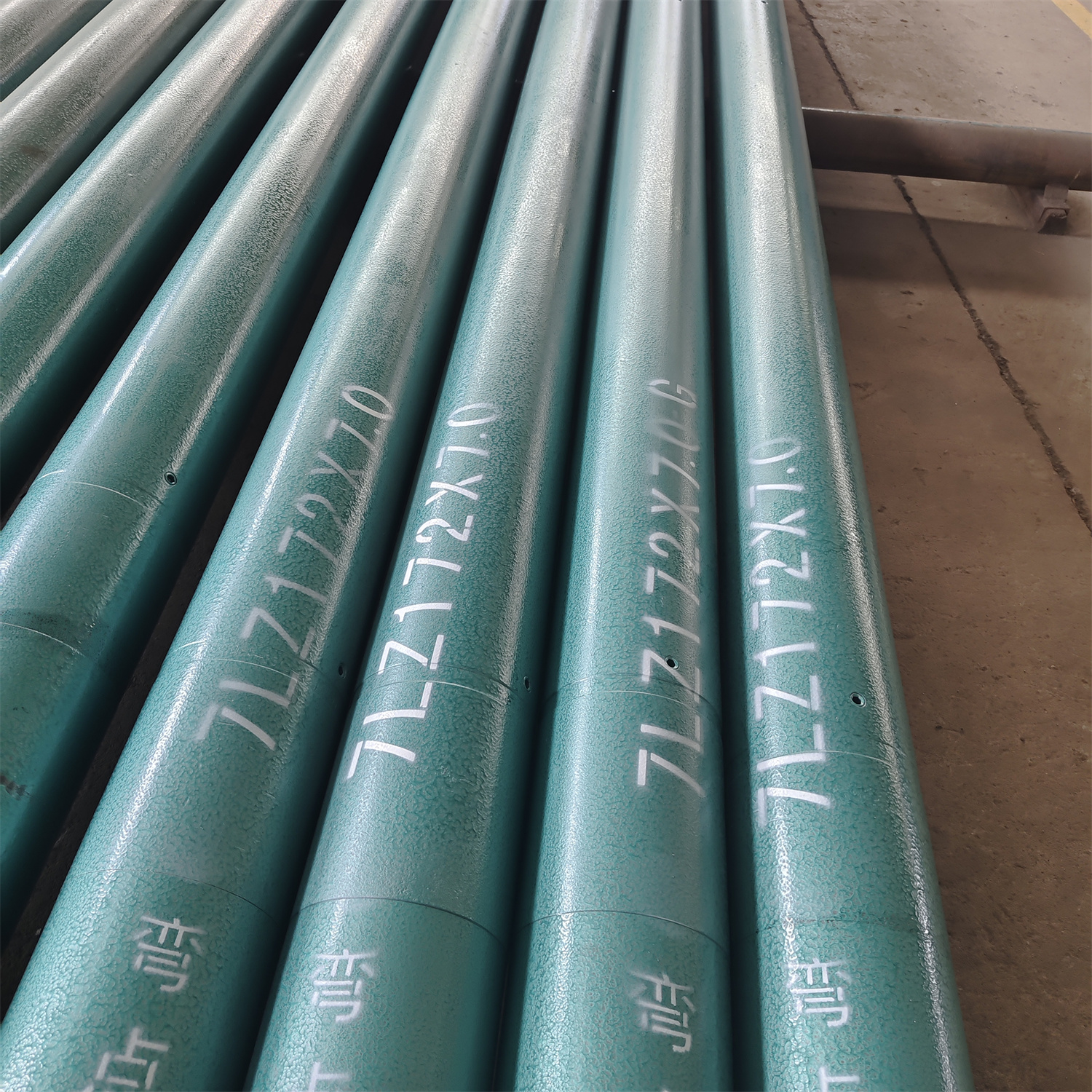

The downhole motor, following the API 7-1 standard, is a device utilized for excavating underground, propelled by pressurized mud. It finds extensive application in both bent and linear boreholes. This instrument boasts a simple structure, remarkable capacity to bear substantial burdens, and the ability to produce substantial rotational force and energy despite its small dimensions. The key constituents of this apparatus encompass the bypass valve, motor, versatile shaft, and propelling shaft.

Product Advantage

API 7-1 downhole motors provide several advantages compared to traditional rotary disk driven drill pipe drilling:

- The flow of drilling fluid directly affects the speed of the downhole motors.

- The torque of the tool is determined by the pressure drop of the drilling fluid passing through the motor.

- The rotary power of the downhole motors is solely used to drive the drill bit, reducing wear on the drill pipe, simplifying operation, improving drilling accuracy, and saving drilling power.

- The downhole motors have a low output speed, high torque, and extended drilling time.

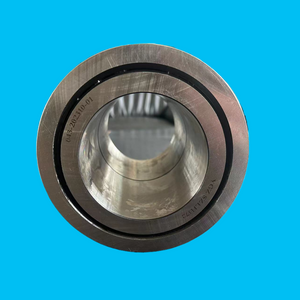

- The downhole motors utilize a multi-row thrust radial ball bearing set that can withstand high pressure and enable fast feeding.

- The downhole motors incorporate welded carbide radial bearings that have a long lifespan.

- The drill bit's water eye can handle a pressure drop of up to 7.0MPa, resulting in a strong water horsepower that effectively cleans the drill bit and prevents mud buildup.

Product Uses

1. Mining Operations:

In mining operations, the Downhole Motors for Mines with Superb Rock-Carrying Capacity play a crucial role in drilling and excavation processes. These motors are specifically designed to withstand the demanding conditions encountered in mines. With their exceptional rock-carrying capacity, they enable efficient drilling and excavation by effectively transporting rocks and debris to the surface. The motors' high displacement mud circulation capability ensures smooth and uninterrupted drilling operations, even in high-volume mud circulation scenarios. Additionally, their outstanding wear resistance ensures prolonged durability, reducing downtime and maintenance costs in mining operations.

2. Oil and Gas Exploration:

The Downhole Motors for Mines with Superb Rock-Carrying Capacity find extensive application in oil and gas exploration activities. These motors are utilized in directional drilling, where precise control and maneuverability are essential. With their powerful rock-carrying capacity, they effectively transport rock cuttings and drilling fluids to the surface, ensuring uninterrupted drilling operations. The motors' ability to handle high mud circulation rates is particularly advantageous in oil and gas exploration, where large volumes of drilling fluids need to be circulated. Furthermore, their exceptional wear resistance enables them to withstand the abrasive conditions encountered in drilling deep into the earth's crust.

3. Geothermal Drilling:

Geothermal drilling involves extracting heat from the earth's interior for various applications. The Downhole Motors for Mines with Superb Rock-Carrying Capacity play a vital role in geothermal drilling operations. These motors excel in transporting rocks and cuttings to the surface, ensuring efficient drilling progress. Their ability to handle high mud circulation rates is crucial in geothermal drilling, where effective heat transfer requires continuous circulation of drilling fluids. Moreover, the motors' exceptional wear resistance ensures longevity, reducing the need for frequent replacements and minimizing downtime in geothermal drilling projects.

4. Construction and Tunneling:

In construction and tunneling projects, the Downhole Motors for Mines with Superb Rock-Carrying Capacity offer significant advantages. These motors are employed in drilling and excavation tasks, where their exceptional rock-carrying capacity proves invaluable. By efficiently transporting rocks and debris to the surface, they facilitate smooth and productive drilling operations. The motors' high displacement mud circulation capability enables effective mud circulation in construction and tunneling projects, ensuring the stability and integrity of the drilled structures. Additionally, their outstanding wear resistance ensures prolonged durability, minimizing maintenance requirements and enhancing overall project efficiency.

5. Water Well Drilling:

Water well drilling requires reliable and efficient drilling equipment to access underground water sources. The Downhole Motors for Mines with Superb Rock-Carrying Capacity find application in water well drilling due to their exceptional performance characteristics. These motors excel in transporting rocks and cuttings to the surface, enabling efficient drilling progress. Their ability to handle high mud circulation rates is particularly advantageous in water well drilling, where continuous circulation of drilling fluids is necessary for effective drilling and well completion. Furthermore, the motors' outstanding wear resistance ensures longevity, reducing downtime and maintenance costs in water well drilling operations.

FAQ

How can I place an order?

Please send us your inquiry with a detailed description of the item or the model number.

If you don't specify any packaging requirements, we will use our standard export packaging.

We will provide you with an order form to fill out and recommend the most suitable model based on the information you provide.

Once you send us your detailed requirements, we will provide you with a quotation.

Can I expect high-quality products?

All production and processing adhere strictly to ISO 9001:2008 and API standards. Our mature production technology ensures that the quality meets international standards. We also welcome third-party inspections, such as BV, SGS, and TUV.

Information you may want to know before making a payment:

1. Payment methods:

We accept T/T (Telegraphic Transfer) or L/C at sight.

2. Shipping options:

For sample orders, we suggest using courier express services like DHL/UPS/FEDEX or shipping by air.

For bulk orders, we suggest shipping by air or by sea.

3. Quality Control

We have our own experienced QC.

There will be strict inspection and testing for every order before shipping out.