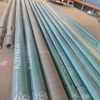

Product Introduction

A downhole motor is a type of drilling tool that is powered by mud. The mud is pumped into the motor through a bypass valve, creating a pressure difference between the inlet and outlet. This pressure difference causes the motor rotator to rotate, transmitting torque and speed to the drill bit through a universal shaft and transmission shaft. The performance of the downhole motor is mainly determined by its properties. This product utilizes advanced coating technology to prevent the rotor from losing its coating, which was a common issue with traditional methods. This improvement greatly enhances the strength and lifespan of the motor. The downhole motor can be used for various drilling techniques, including directional drilling, horizontal drilling, composite drilling, cluster wells, sidetrack wells, and well workover operations.

Product Advantage

1. Each drilling motor is equipped with a sub to capture the rotor.

2. Additional floating upper subs, discharge subs, or dedicated subs can be attached to drilling motors.

3. Drilling motors can be used with both water-based mud (WBM) and oil-based mud (OBM).

4. The housing on the drilling motor can be modified within a range of 0 to 3°.

5. Stabilizer choices consist of screw-on, fixed, or blank variations.

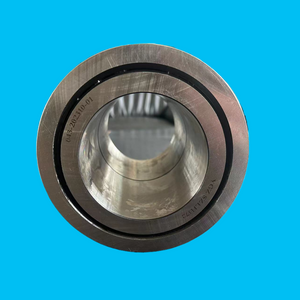

6. The bearing mandrel in the drilling motor is specially designed to withstand high torque power sections.

Product Uses

1. Mining Operations:

In mining operations, the Downhole Motors for Mines with Superb Rock-Carrying Capacity play a crucial role in drilling and excavation processes. These motors are specifically designed to withstand the demanding conditions encountered in mines. With their exceptional rock-carrying capacity, they enable efficient drilling and excavation by effectively transporting rocks and debris to the surface. The motors' high displacement mud circulation capability ensures smooth and uninterrupted drilling operations, even in high-volume mud circulation scenarios. Additionally, their outstanding wear resistance ensures prolonged durability, reducing downtime and maintenance costs in mining operations.

2. Oil and Gas Exploration:

The Downhole Motors for Mines with Superb Rock-Carrying Capacity find extensive application in oil and gas exploration activities. These motors are utilized in directional drilling, where precise control and maneuverability are essential. With their powerful rock-carrying capacity, they effectively transport rock cuttings and drilling fluids to the surface, ensuring uninterrupted drilling operations. The motors' ability to handle high mud circulation rates is particularly advantageous in oil and gas exploration, where large volumes of drilling fluids need to be circulated. Furthermore, their exceptional wear resistance enables them to withstand the abrasive conditions encountered in drilling deep into the earth's crust.

3. Geothermal Drilling:

Geothermal drilling involves extracting heat from the earth's interior for various applications. The Downhole Motors for Mines with Superb Rock-Carrying Capacity play a vital role in geothermal drilling operations. These motors excel in transporting rocks and cuttings to the surface, ensuring efficient drilling progress. Their ability to handle high mud circulation rates is crucial in geothermal drilling, where effective heat transfer requires continuous circulation of drilling fluids. Moreover, the motors' exceptional wear resistance ensures longevity, reducing the need for frequent replacements and minimizing downtime in geothermal drilling projects.

4. Construction and Tunneling:

In construction and tunneling projects, the Downhole Motors for Mines with Superb Rock-Carrying Capacity offer significant advantages. These motors are employed in drilling and excavation tasks, where their exceptional rock-carrying capacity proves invaluable. By efficiently transporting rocks and debris to the surface, they facilitate smooth and productive drilling operations. The motors' high displacement mud circulation capability enables effective mud circulation in construction and tunneling projects, ensuring the stability and integrity of the drilled structures. Additionally, their outstanding wear resistance ensures prolonged durability, minimizing maintenance requirements and enhancing overall project efficiency.

5. Water Well Drilling:

Water well drilling requires reliable and efficient drilling equipment to access underground water sources. The Downhole Motors for Mines with Superb Rock-Carrying Capacity find application in water well drilling due to their exceptional performance characteristics. These motors excel in transporting rocks and cuttings to the surface, enabling efficient drilling progress. Their ability to handle high mud circulation rates is particularly advantageous in water well drilling, where continuous circulation of drilling fluids is necessary for effective drilling and well completion. Furthermore, the motors' outstanding wear resistance ensures longevity, reducing downtime and maintenance costs in water well drilling operations.

FAQ

1. What is the estimated delivery time for your products?

The delivery time will vary depending on the model and quantity of the order. Typically, if the machines are in stock, it will take around 30 days.

2. What are the accepted payment methods?

We usually accept payments through T/T or L/C.

3. How are the products shipped?

For sample orders, we recommend using courier express services such as DHL/UPS/FEDEX or air shipping. For bulk orders, air or sea shipping is suggested.

4. How is the quality of the products ensured?

We have our own experienced quality control team. Every order undergoes strict inspection and testing before being shipped out.

5. What is the packaging like?

The products are packed in white boxes or color boxes upon request. The outer packaging consists of cartons or pallets.

6. What are the terms of shipment?

The products will be shipped approximately 30 days after receiving the advance payment, or as agreed upon by both parties.

7. Which ports are used for shipment?

The products can be shipped from Tianjin, Qingdao, Shanghai, or any other required port, either by sea or air.

8. Is there any inspection conducted before delivery?

Yes, there is a 100% testing process carried out before the products are delivered.