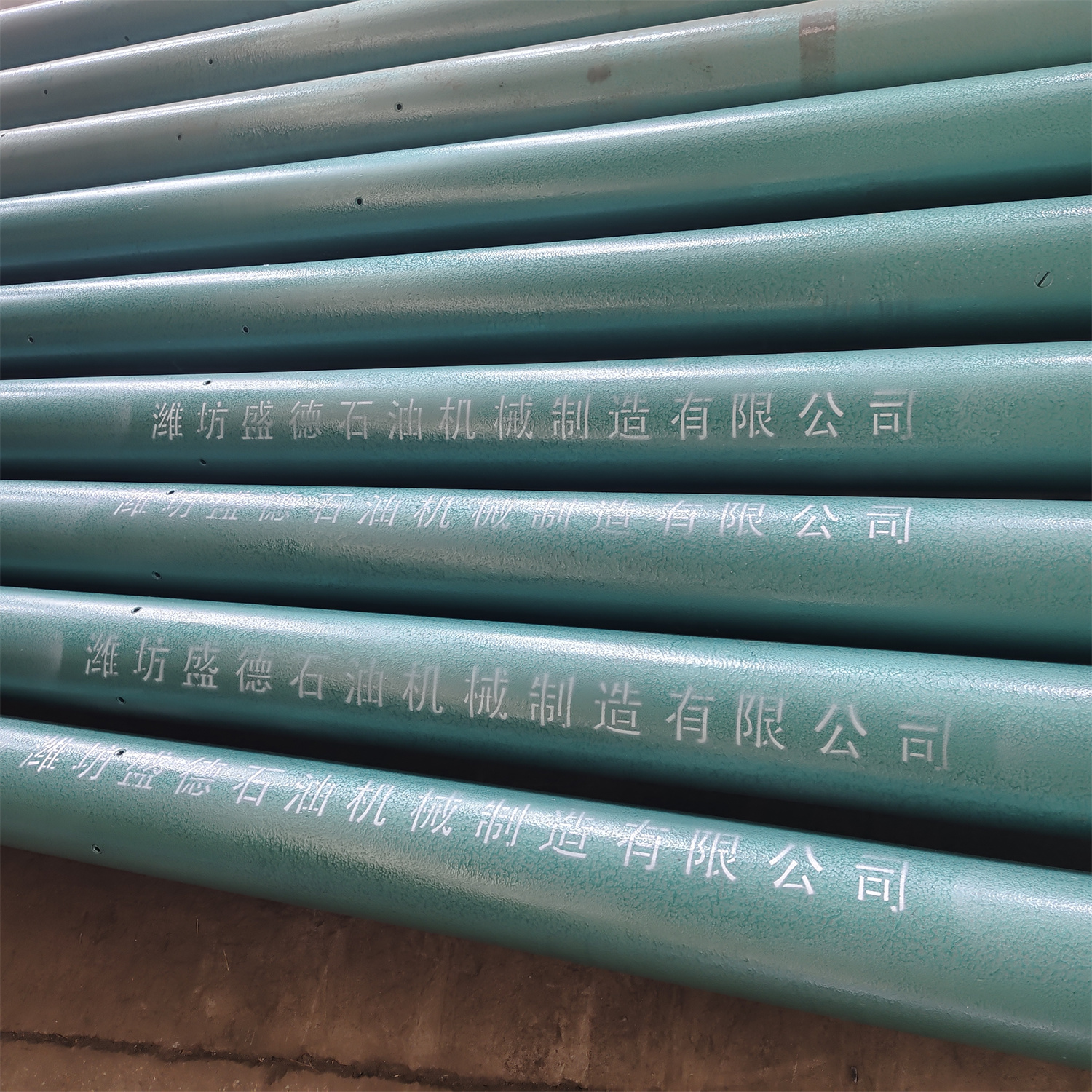

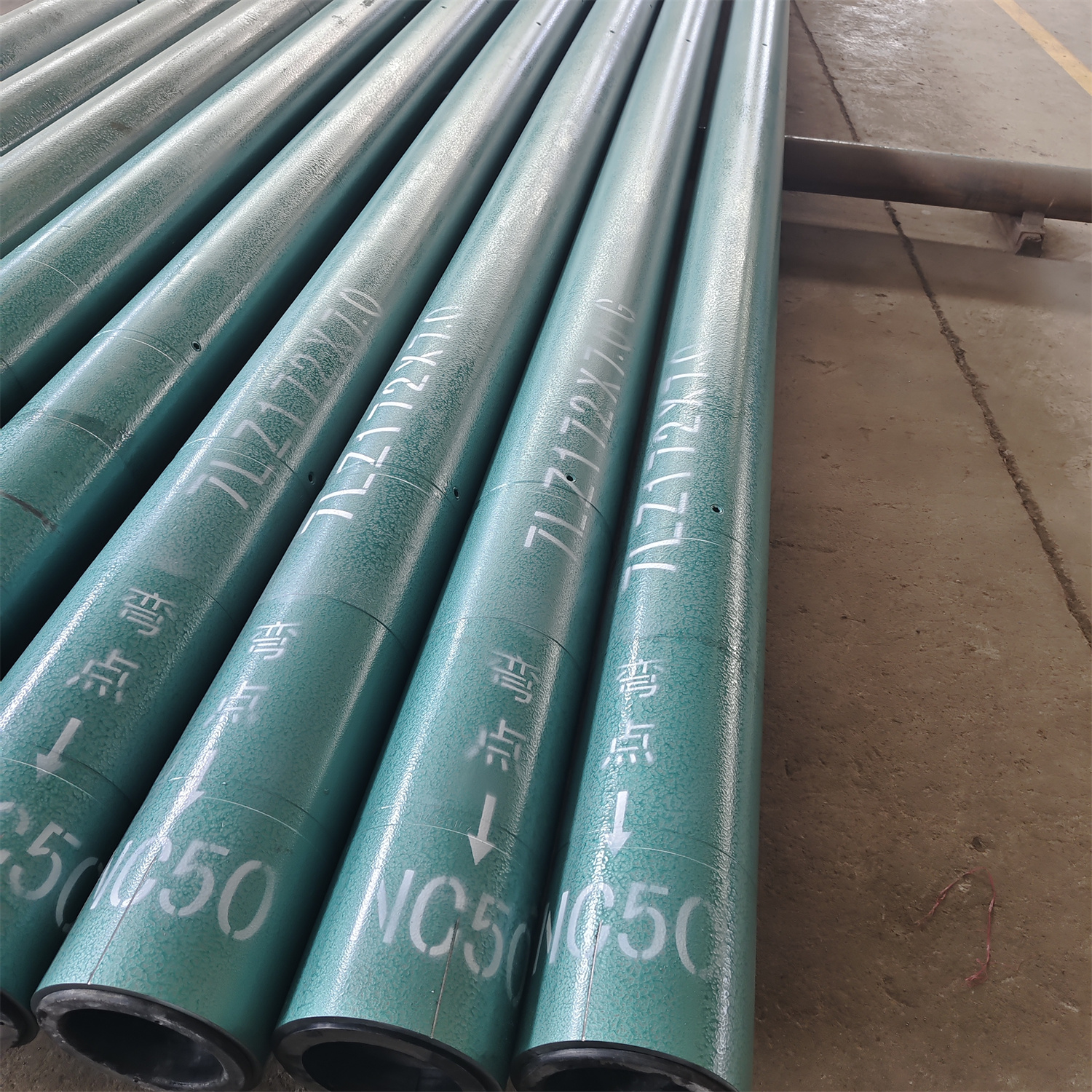

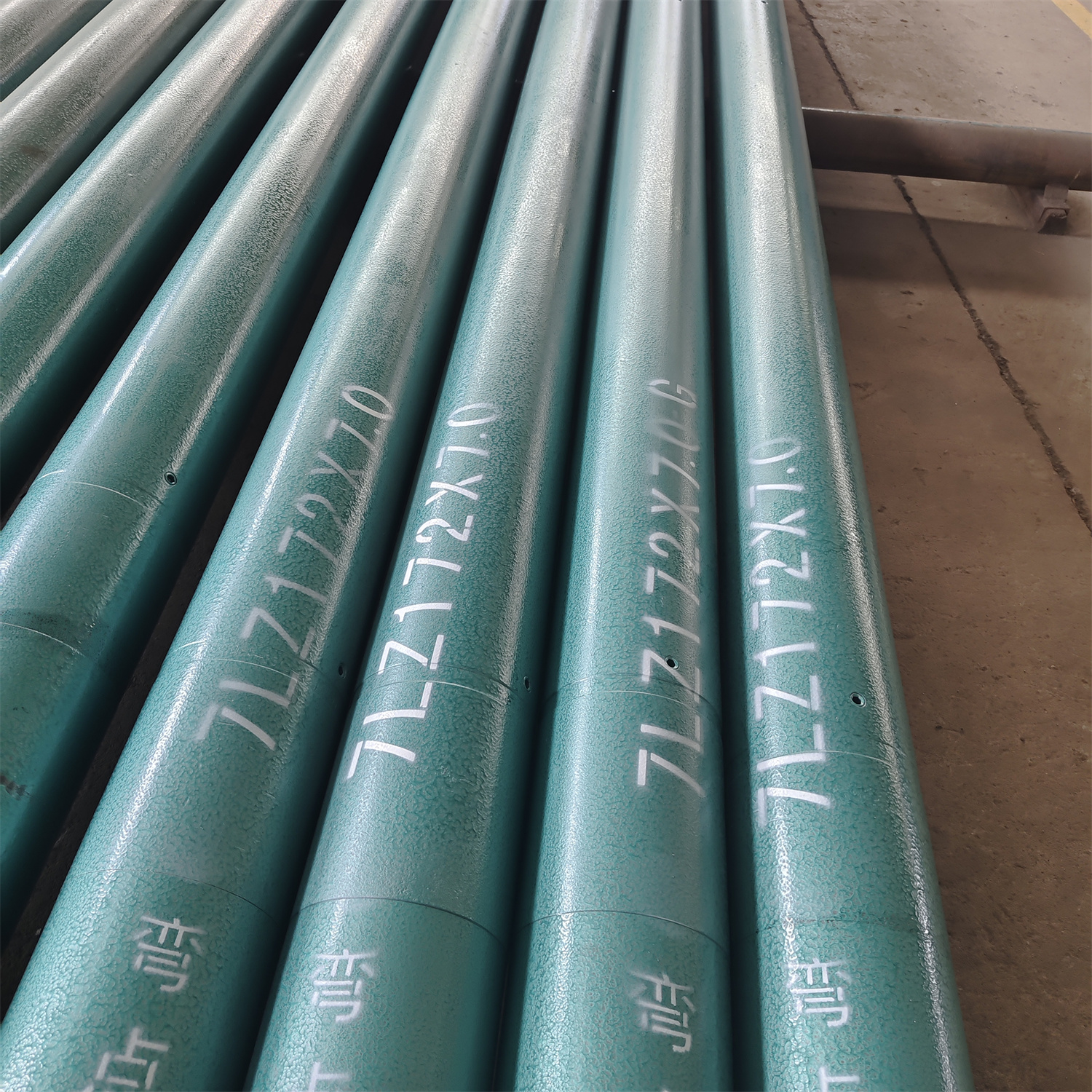

Product Introduction

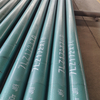

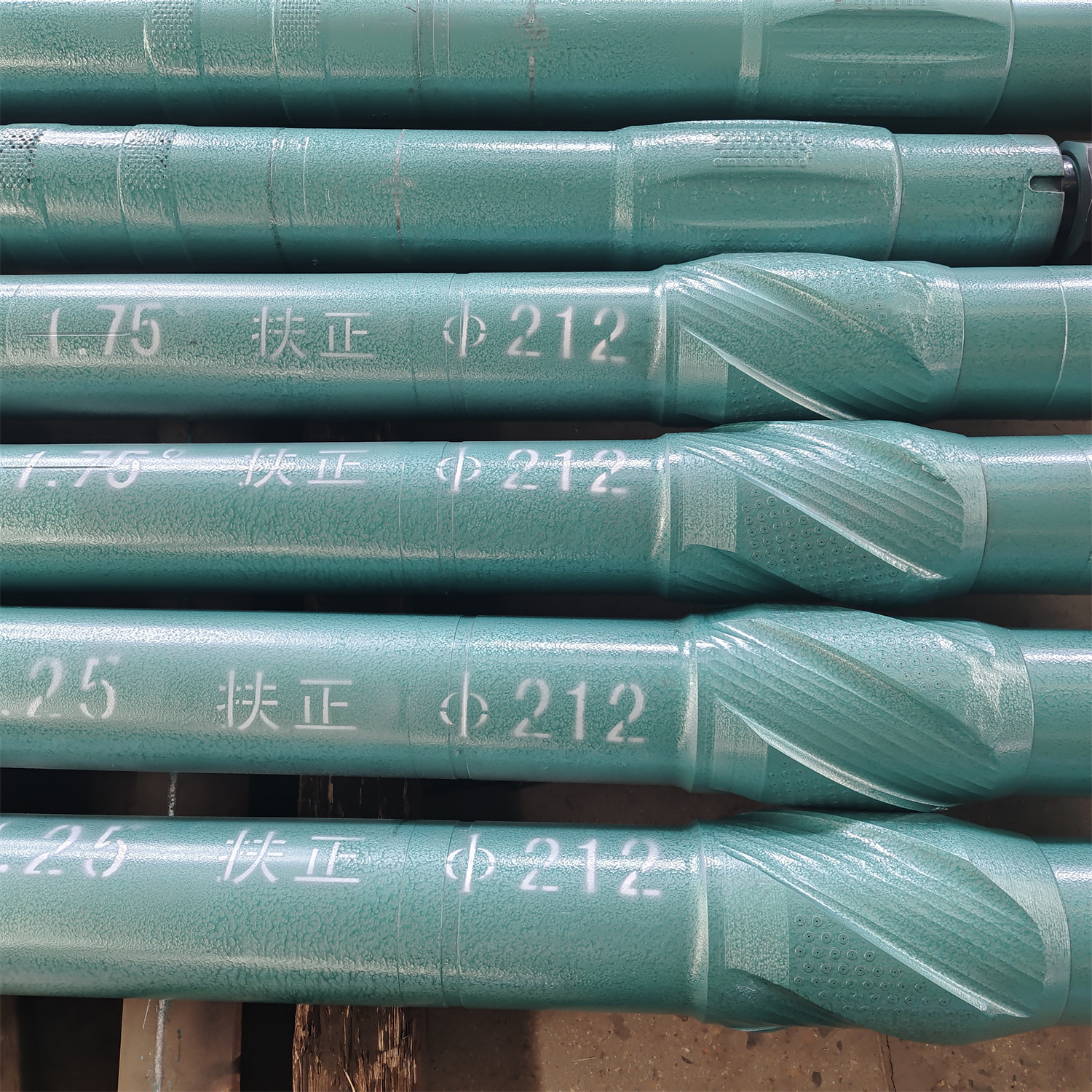

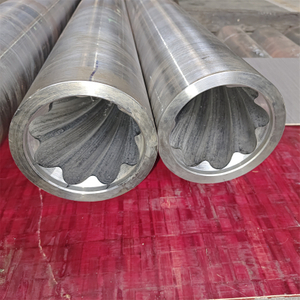

Introducing our Low Speed and High Torque Downhole Motor, designed for tackling complex well conditions with utmost efficiency. This professional-grade product is engineered to deliver exceptional performance, ensuring optimal power output when faced with challenging drilling operations.

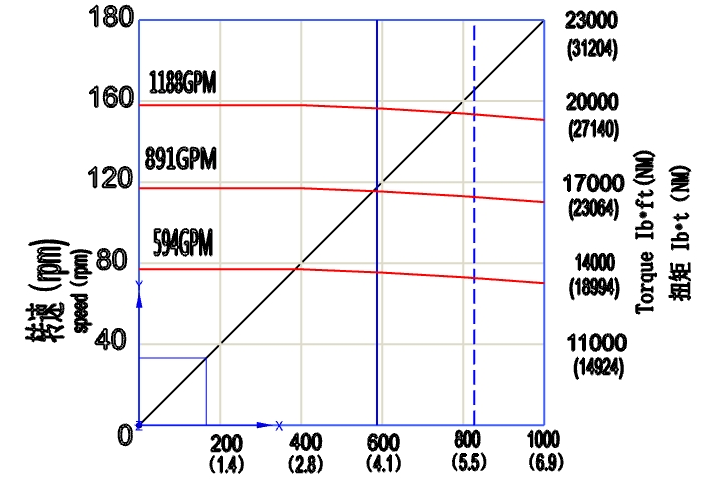

With its low speed and high torque capabilities, our Downhole Motor is specifically crafted to provide superior power output, even in the most demanding well conditions. This ensures that you can achieve higher levels of productivity and efficiency, ultimately saving valuable time and resources.

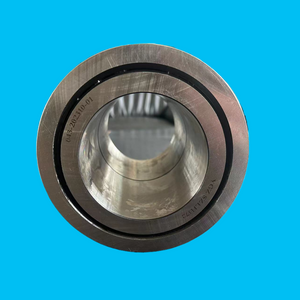

Our Downhole Motor is built to withstand the harshest drilling environments, making it the ideal choice for professionals in the oil and gas industry. Its robust construction and advanced technology enable it to operate reliably and efficiently, ensuring consistent performance throughout the drilling process.

Experience the benefits of our Low Speed and High Torque Downhole Motor and unlock the potential for increased productivity and power output. Trust in our professional-grade product to deliver exceptional results, even in the most complex well conditions.

Product Advantage

1. Downhole motors with low speed and high torque can enhance the speed and effectiveness of drilling by delivering increased torque to facilitate rapid penetration into formations.

2. Additionally, the utilization of low speed and high torque downhole motors can lead to reduced drilling expenses, while also lessening the load on drilling rigs and minimizing energy consumption.

3. The structure of these downhole motors, characterized by low speed and high torque, is relatively uncomplicated, easy to maintain, and highly reliable, making it well-suited for drilling operations in diverse and intricate formations.

4. The low-speed and high torque downhole motor possesses exceptional control capabilities over the trajectory of the wellbore, which proves advantageous in enhancing the overall quality of drilling.

Product Uses

1. Application Scenario: Drilling in Hard Formations with High Torque Requirements

Description: The Low Speed and High Torque Downhole Motor is specifically designed to excel in drilling operations conducted in challenging geological formations characterized by extreme hardness. These formations often pose significant difficulties due to their resistance to drilling tools and require specialized equipment to overcome these challenges. The downhole motor's exceptional torque capabilities enable efficient penetration and advancement through such formations, ensuring successful drilling operations in hard rock, cemented formations, or other similarly challenging environments.

2. Application Scenario: Complex Well Conditions with Varying Drilling Challenges

Description: The Low Speed and High Torque Downhole Motor is highly suitable for deployment in wells that present a multitude of complex conditions, requiring adaptability and robust performance. These conditions may include directional drilling, extended reach drilling, horizontal drilling, or drilling through unstable formations. The downhole motor's ability to provide consistent high torque output allows for precise control and maneuverability, enabling operators to navigate through intricate well paths and overcome obstacles effectively. Its reliable performance ensures optimal drilling progress and minimizes the risk of operational delays or equipment failures.

3. Application Scenario: High Torque Demands for Efficient Drilling Operations

Description: The Low Speed and High Torque Downhole Motor is specifically engineered to meet the requirements of drilling operations that demand substantial torque output. In applications where conventional drilling methods may prove insufficient, such as drilling large-diameter boreholes, reaming, or milling operations, this downhole motor excels. Its high torque capabilities enable efficient and effective drilling, ensuring rapid progress and reduced drilling time. By providing the necessary power and torque, the downhole motor enhances drilling efficiency and productivity, ultimately resulting in cost savings and improved overall operational performance.

4. Application Scenario: Drilling in Extreme Conditions and Hostile Environments

Description: The Low Speed and High Torque Downhole Motor is designed to withstand and excel in extreme drilling conditions and hostile environments. These scenarios may include drilling in high-temperature formations, high-pressure environments, or corrosive drilling fluids. The downhole motor's robust construction and advanced materials ensure reliable performance and longevity under such challenging circumstances. Its ability to deliver high torque even in harsh environments allows operators to maintain drilling progress and achieve successful outcomes, minimizing downtime and maximizing operational efficiency.

5. Application Scenario: Enhanced Drilling Performance in Offshore Operations

Description: The Low Speed and High Torque Downhole Motor finds extensive application in offshore drilling operations, where the demands for efficient and reliable drilling are paramount. Offshore drilling often involves complex geological formations, challenging well profiles, and strict operational timelines. The downhole motor's high torque capabilities enable efficient drilling progress, ensuring timely completion of offshore projects. Its ability to overcome challenging conditions, such as drilling through salt formations or encountering high-pressure zones, enhances operational safety and success, making it an ideal choice for offshore drilling applications.

Certifications

We have effectively obtained certifications for API Q1 and API 7-1 systems, in addition to ISO9001 for managing quality, ISO14001 for managing the environment, ISO45001 for managing occupational health, measurement management, intellectual property management, and managing green enterprises.

FAQ

1. What is a downhole motor and how does it work?

A downhole motor is a type of drilling tool used in the oil and gas industry. It is designed to provide low speed and high torque power to rotate the drill bit during drilling operations. The motor is placed downhole, or underground, and is powered by drilling fluid or mud.

2. What are the advantages of using a low speed and high torque downhole motor?

A low speed and high torque downhole motor offers several advantages. Firstly, it allows for efficient drilling in challenging formations or hard rock. The high torque enables the motor to overcome resistance and maintain drilling progress. Additionally, the low speed reduces wear and tear on the motor, increasing its lifespan and reducing maintenance costs.

3. How does the delivery time of the low speed and high torque downhole motor affect drilling operations?

The delivery time of the downhole motor is crucial for drilling operations. Delays in receiving the motor can result in project delays and increased costs. It is important to work with a reliable supplier who can provide accurate delivery estimates and ensure timely delivery to avoid any disruptions to drilling activities.

4. How does the quality of the low speed and high torque downhole motor impact drilling performance?

The quality of the downhole motor directly affects drilling performance. A high-quality motor will have better durability, reliability, and efficiency, resulting in improved drilling operations. It is essential to choose a reputable manufacturer that adheres to strict quality control standards to ensure the motor meets the required specifications and performs optimally.

5. How does the downhole motor handle different formation conditions?

The downhole motor is designed to handle various formation conditions. Its low speed and high torque capabilities allow it to effectively drill through different types of rock formations, including soft, medium, and hard formations. The motor's power and torque can be adjusted to match the specific requirements of the formation, ensuring efficient drilling and successful completion of the project.