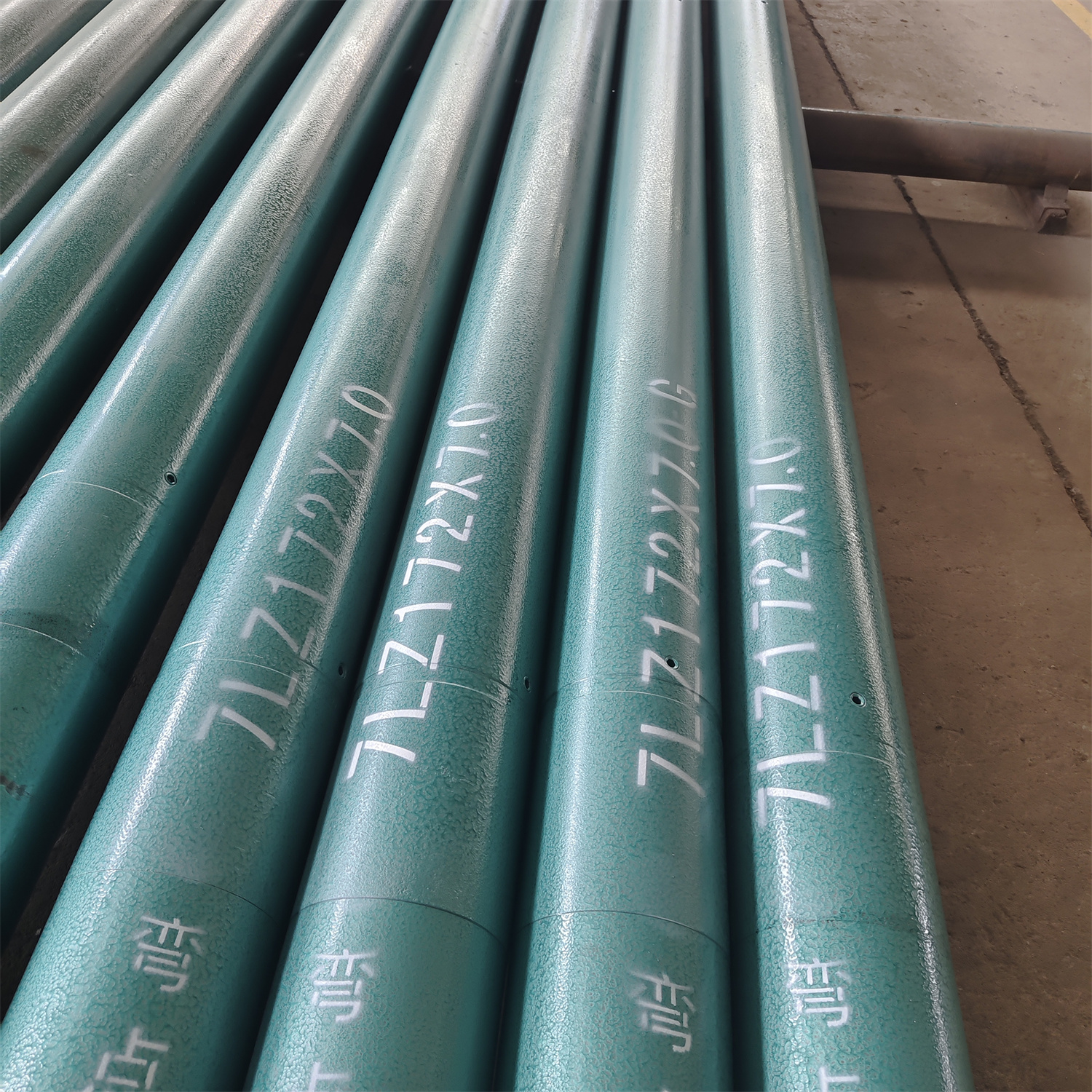

Product Introduction

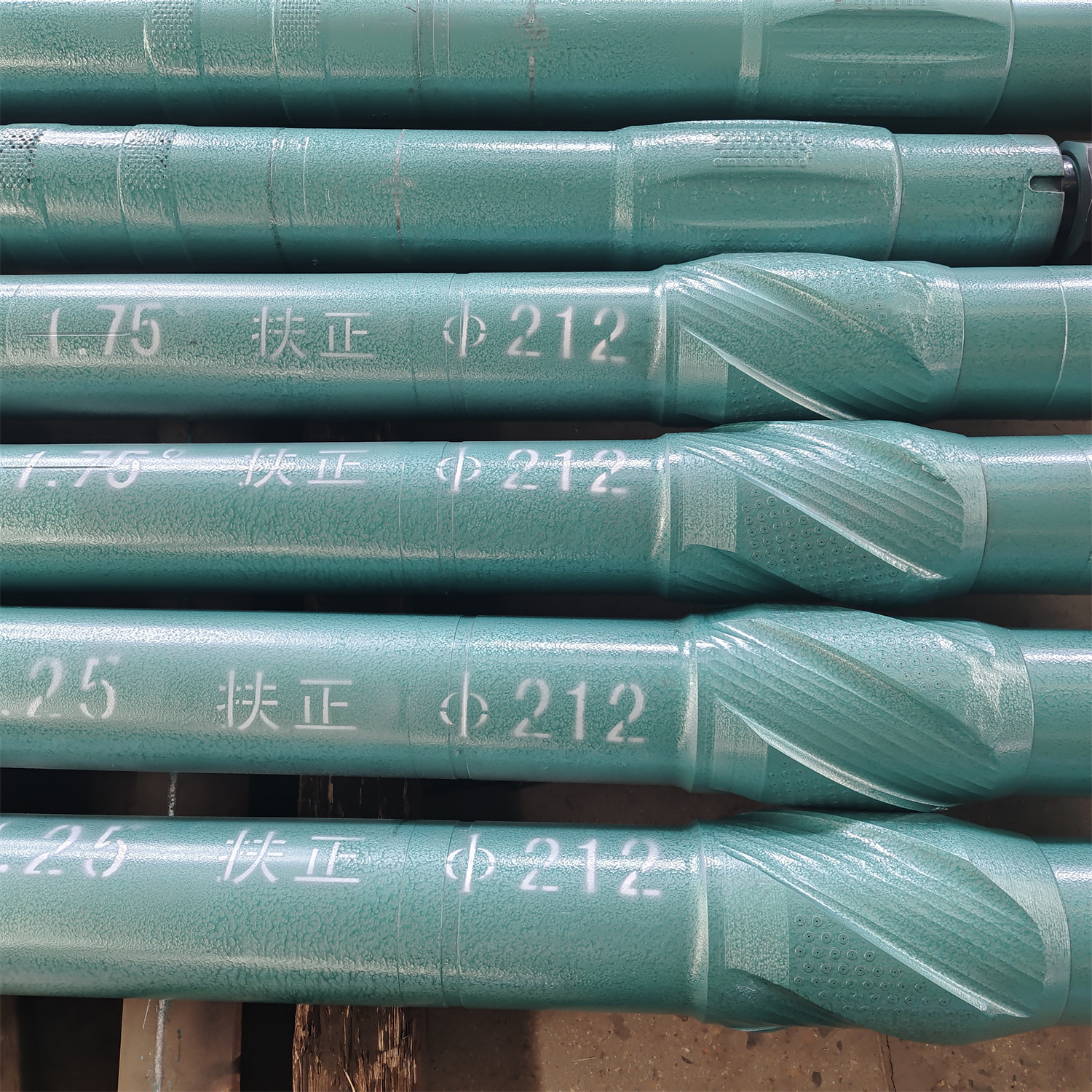

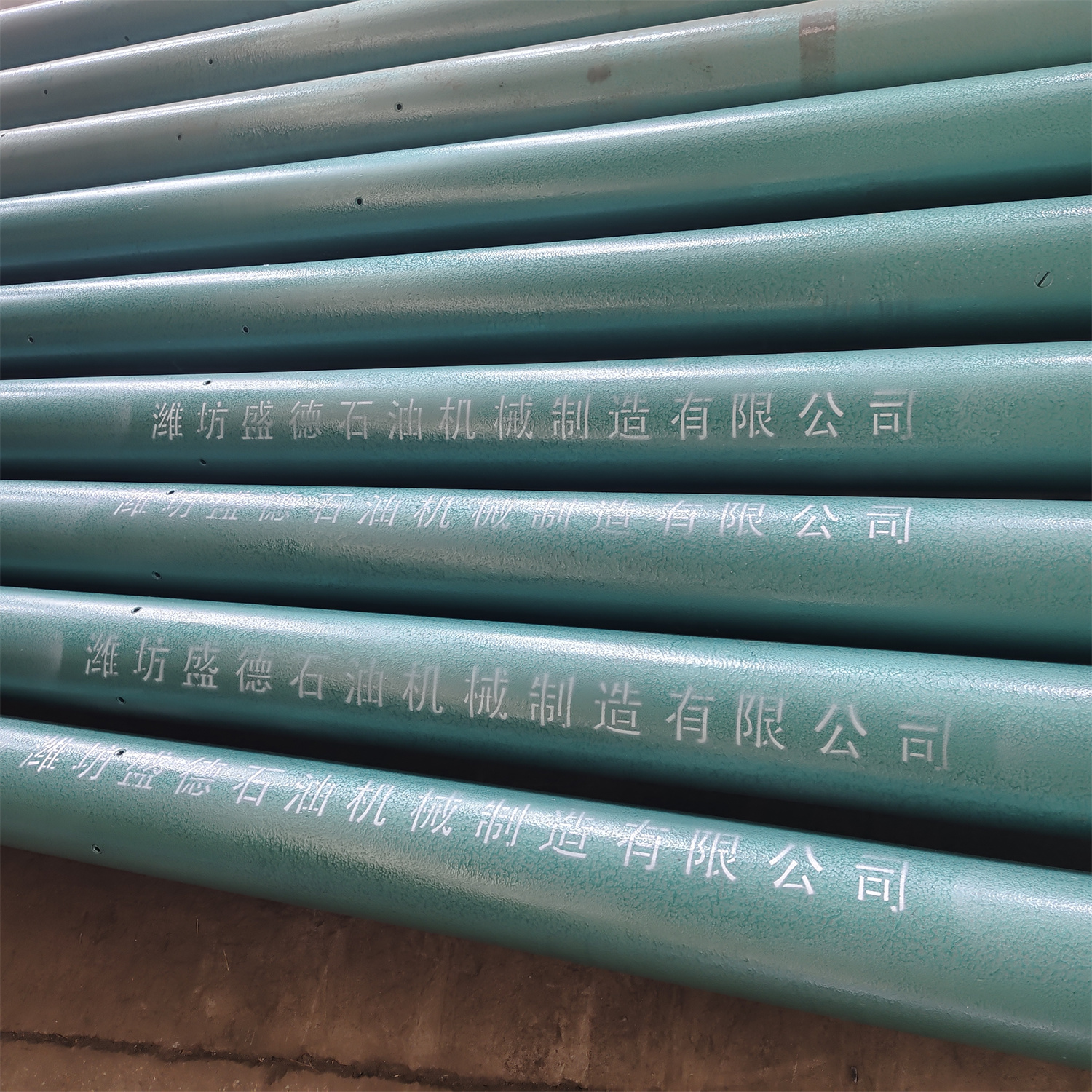

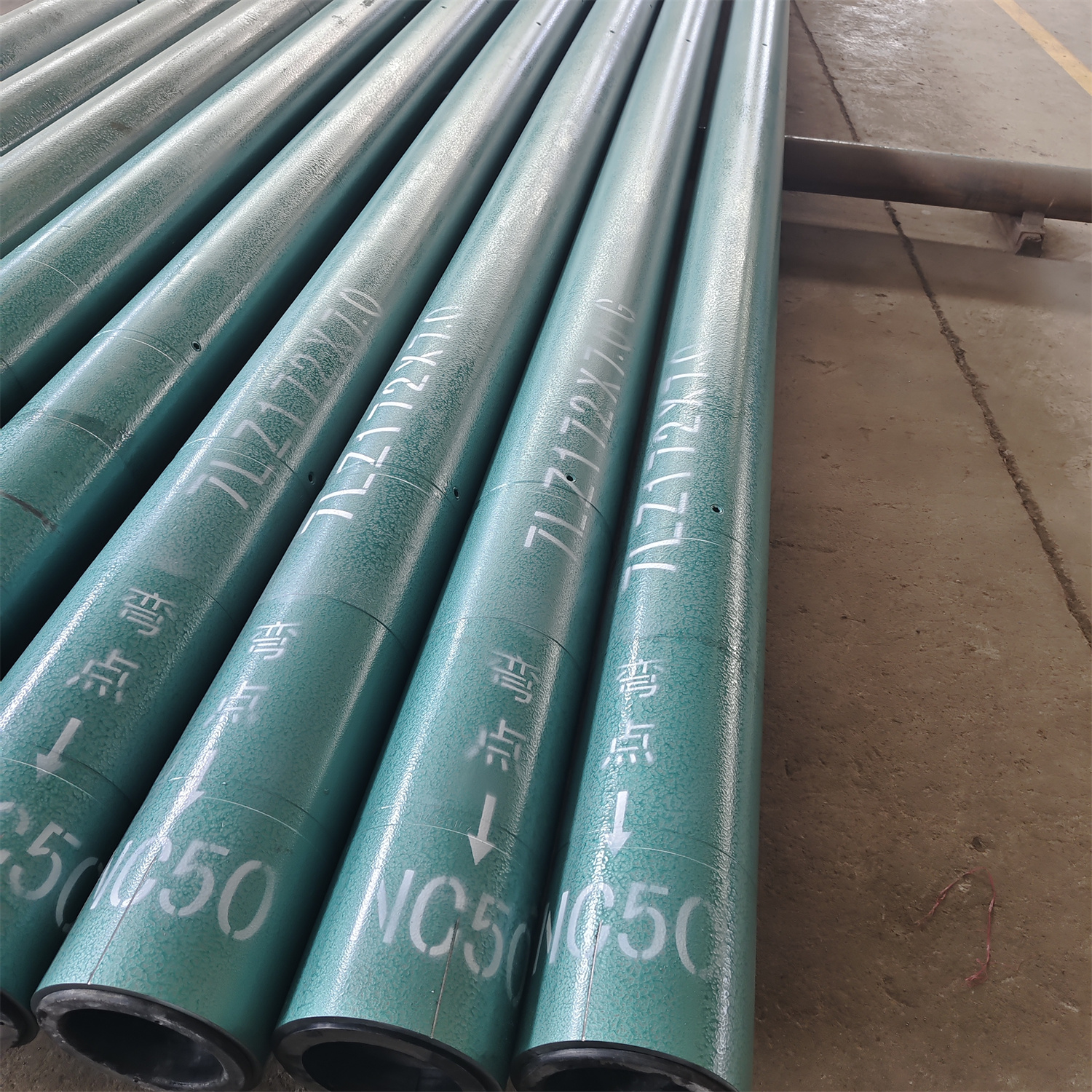

API 7-1 standard downhole motor is a downhole power drilling tool, driven by high pressure mud, widely used in directional and straight wells. It has simple structure, good overload performance, and can get large torque and power in small size. It mainly consists of four main parts, such as bypass valve, motor, universal shaft and drive shaft.

Product Advantage

API 7-1 downhole motors offer the following advantages over conventional rotary disk driven drill pipe drilling:

- Drilling fluid input flow is directly proportional to the downhole motors output speed.

- The torque of the tool is linearly related to the pressure drop of the drilling fluid through the motor.

- The rotary power of the downhole motors is only used to drive the drill bit, which reduces wear on the drill pipe, simplifies operation, improves drilling accuracy and saves drilling power.

- The output speed of the downhole motors is low, the torque is high, and the pure drilling time is long.

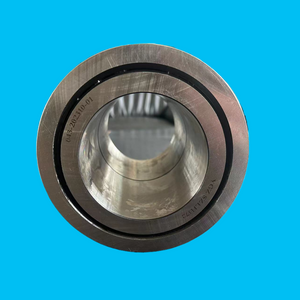

- The downhole motors adopts multi-row thrust radial ball bearing set, which is resistant to high pressure and fast in feed.

- The downhole motors adopt welded carbide radial bearings with long service life.

- The pressure drop of the water eye of the drill bit is up to 7.0MPa, and the water horsepower of the drill bit is large, which flushes the drill bit cleanly and prevents the mud pack of the drill bit.

Product Uses

1. Mining Operations:

In mining operations, the Downhole Motors for Mines with Superb Rock-Carrying Capacity play a crucial role in drilling and excavation processes. These motors are specifically designed to withstand the demanding conditions encountered in mines. With their exceptional rock-carrying capacity, they enable efficient drilling and excavation by effectively transporting rocks and debris to the surface. The motors' high displacement mud circulation capability ensures smooth and uninterrupted drilling operations, even in high-volume mud circulation scenarios. Additionally, their outstanding wear resistance ensures prolonged durability, reducing downtime and maintenance costs in mining operations.

2. Oil and Gas Exploration:

The Downhole Motors for Mines with Superb Rock-Carrying Capacity find extensive application in oil and gas exploration activities. These motors are utilized in directional drilling, where precise control and maneuverability are essential. With their powerful rock-carrying capacity, they effectively transport rock cuttings and drilling fluids to the surface, ensuring uninterrupted drilling operations. The motors' ability to handle high mud circulation rates is particularly advantageous in oil and gas exploration, where large volumes of drilling fluids need to be circulated. Furthermore, their exceptional wear resistance enables them to withstand the abrasive conditions encountered in drilling deep into the earth's crust.

3. Geothermal Drilling:

Geothermal drilling involves extracting heat from the earth's interior for various applications. The Downhole Motors for Mines with Superb Rock-Carrying Capacity play a vital role in geothermal drilling operations. These motors excel in transporting rocks and cuttings to the surface, ensuring efficient drilling progress. Their ability to handle high mud circulation rates is crucial in geothermal drilling, where effective heat transfer requires continuous circulation of drilling fluids. Moreover, the motors' exceptional wear resistance ensures longevity, reducing the need for frequent replacements and minimizing downtime in geothermal drilling projects.

4. Construction and Tunneling:

In construction and tunneling projects, the Downhole Motors for Mines with Superb Rock-Carrying Capacity offer significant advantages. These motors are employed in drilling and excavation tasks, where their exceptional rock-carrying capacity proves invaluable. By efficiently transporting rocks and debris to the surface, they facilitate smooth and productive drilling operations. The motors' high displacement mud circulation capability enables effective mud circulation in construction and tunneling projects, ensuring the stability and integrity of the drilled structures. Additionally, their outstanding wear resistance ensures prolonged durability, minimizing maintenance requirements and enhancing overall project efficiency.

5. Water Well Drilling:

Water well drilling requires reliable and efficient drilling equipment to access underground water sources. The Downhole Motors for Mines with Superb Rock-Carrying Capacity find application in water well drilling due to their exceptional performance characteristics. These motors excel in transporting rocks and cuttings to the surface, enabling efficient drilling progress. Their ability to handle high mud circulation rates is particularly advantageous in water well drilling, where continuous circulation of drilling fluids is necessary for effective drilling and well completion. Furthermore, the motors' outstanding wear resistance ensures longevity, reducing downtime and maintenance costs in water well drilling operations.

FAQ

How can I place order?

A: You can contact us by email about your order details, or place order on line.

How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank), L/C, D/P, Western Union are the most usual ways we are using. If you want to use other way, please tell me, we can discuss.

What’s the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pr-epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 7-15days if we don’t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.