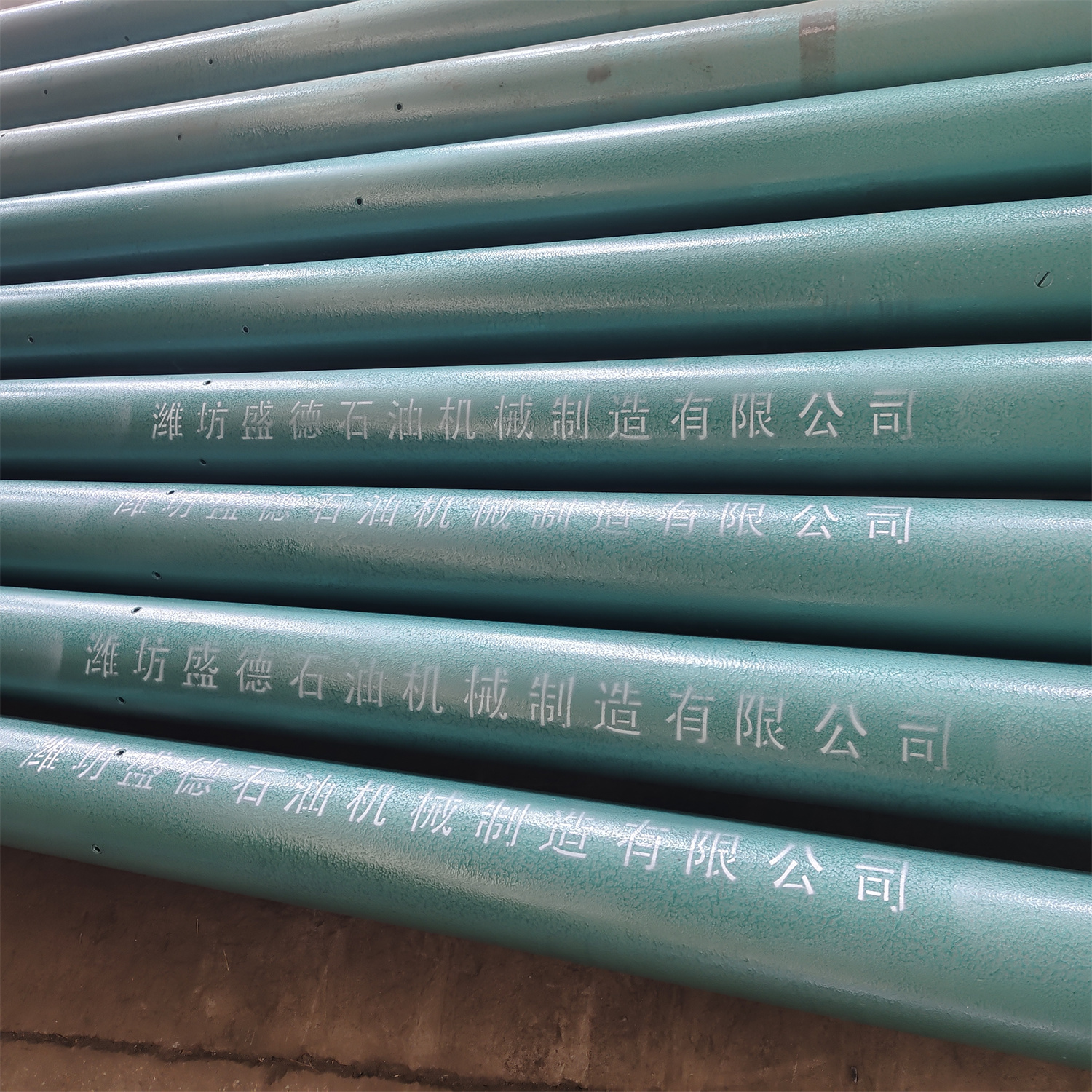

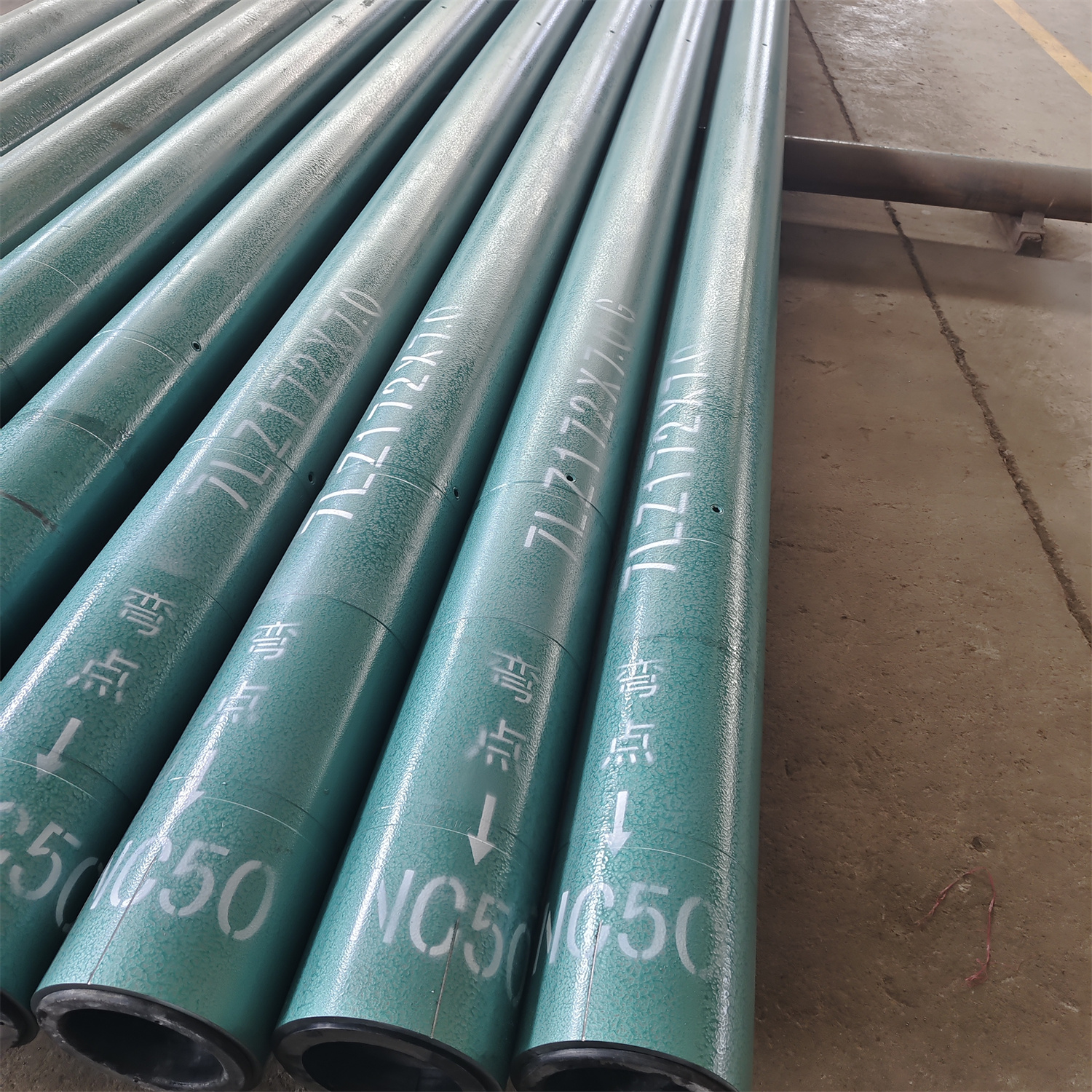

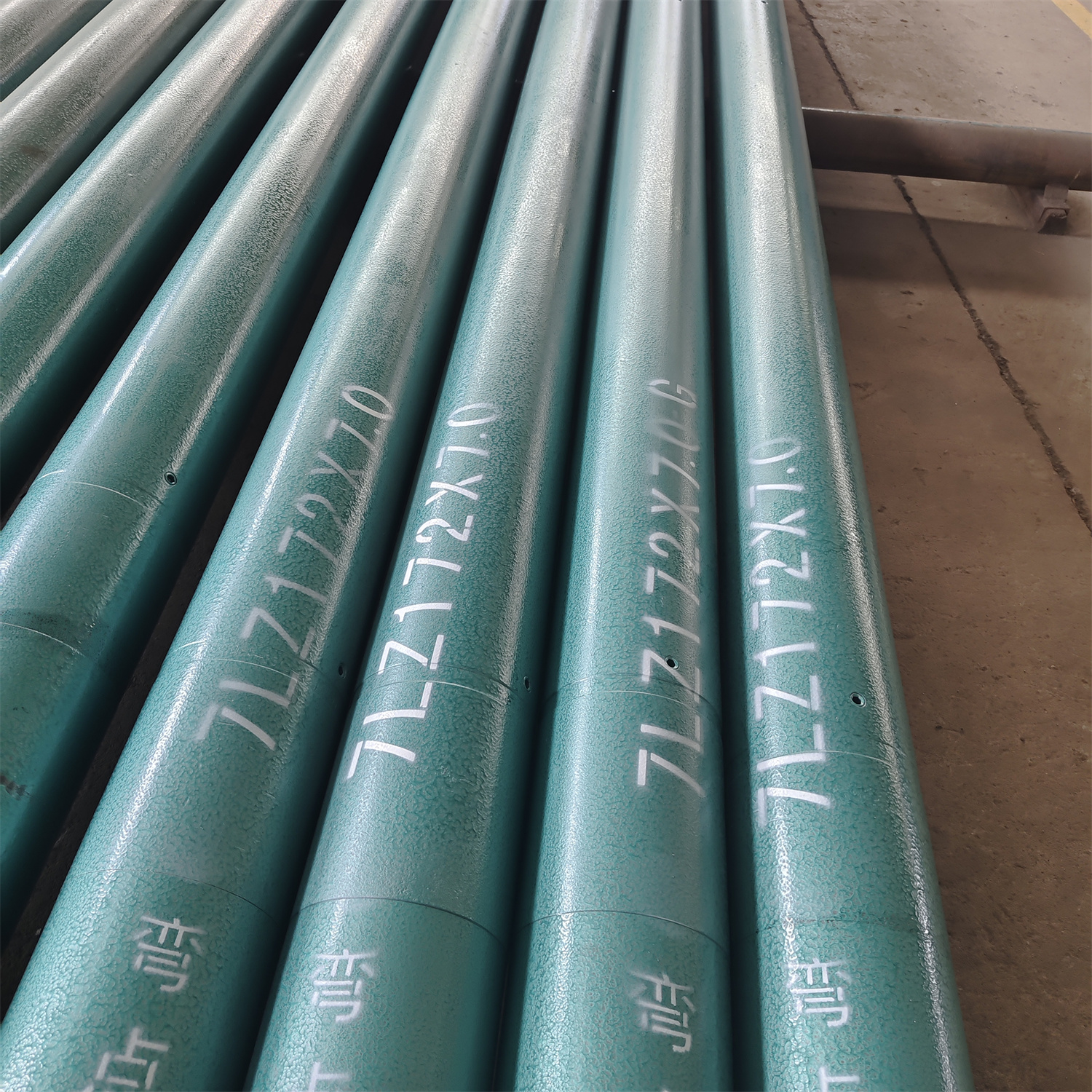

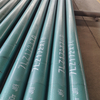

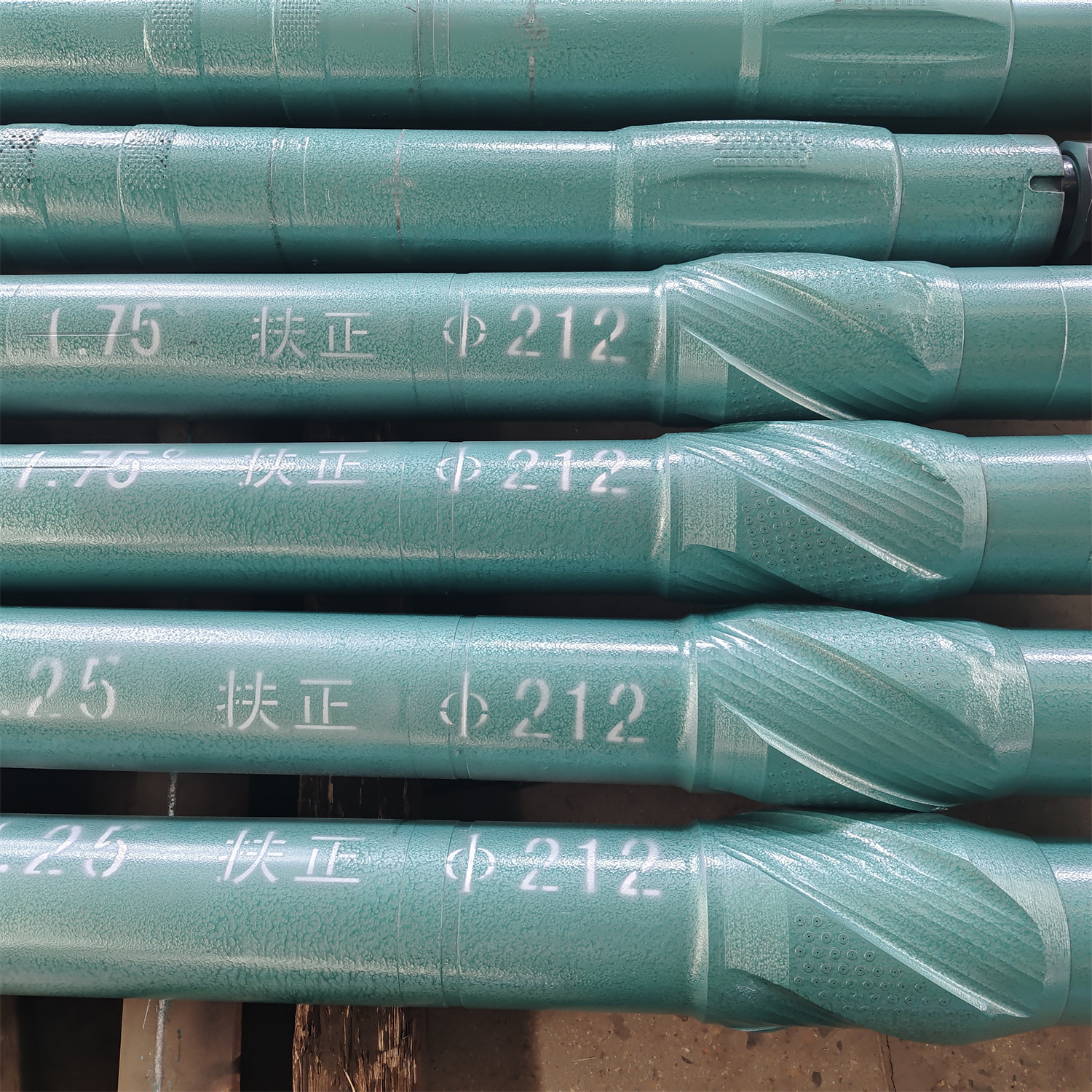

Product Introduction

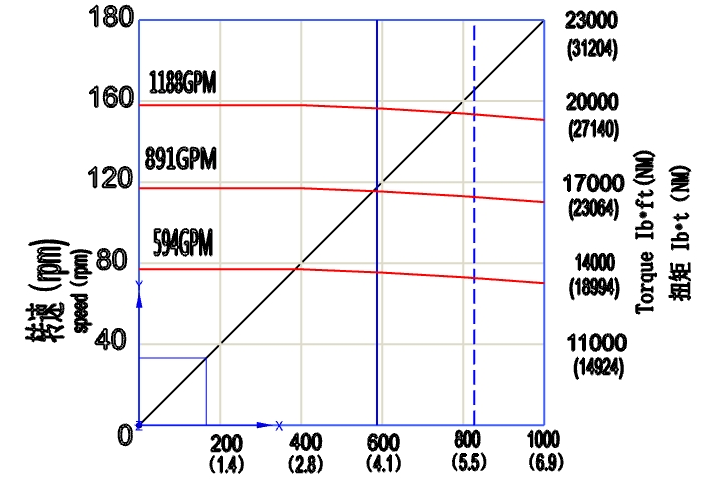

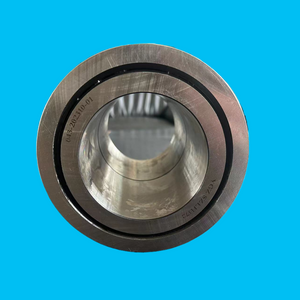

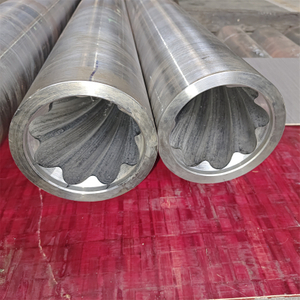

The Positive Displacement motor downhole motor is a kind of downhole power drilling tool powered by drilling fluid, also known as Positive Displacement motor (PDM). Its working principle is as follows: when the mud pump pumped mud flow through the bypass valve into the motor, a certain pressure difference is formed at the inlet and outlet of the motor, which pushes the rotor to rotate around the axis of the stator, and transmits the rotational speed and torque to the drilling bit through the cardan shaft and the transmission shaft to realize the drilling operation.

Product Advantage

Positive Displacement motor is a downhole power drilling tool powered by drilling fluid. Its advantages are as follows:

- Same size as the original borehole: The downhole motor is a Positive Displacement motor that drills exactly the same size borehole as the original borehole without having to drill down to enlarge the borehole again.

- Drills through bridging plugs: When there are bridging plugs in the well, the sdownhole motor can drill through them and circulate the bottom of the well cleanly before starting the incline.

- Small difference in speed: the difference between the idling speed and the working speed of the downhole motors is small (compared with the turbine), which is favorable for the selection of drill bits.

Product Uses

Positive Displacement motor downhole motors are mainly used in the following scenarios:

- Directional well sloping section: In the case of stable formation, regular borehole and low sloping rate, downhole motors can meet the requirement of borehole trajectory control.

- Horizontal section: downhole motors can be used for horizontal section drilling, especially in the case of long horizontal section and large borehole size, downhole motors can improve drilling efficiency and drilling quality.

- Underbalanced drilling: downhole motors can be used for underbalanced drilling, especially in the case of small borehole size, downhole motors can improve drilling efficiency and drilling quality.

- Small borehole drilling: downhole motors can be used for small borehole drilling, especially in the case of small borehole size, downhole motors can improve drilling efficiency and drilling quality.

- Deep borehole drilling: downhole motors can be used for deep borehole drilling, especially in the case of small borehole size, screw drilling tools can improve drilling efficiency and drilling quality.

Overall, screw drilling tools are a kind of efficient, reliable and adaptable downhole power drilling tools, which can improve drilling efficiency and drilling quality and reduce drilling cost.

Certifications

We have obtained API Q1 and API 7-1 system certifications, as well as ISO9001 quality management system certification, ISO14001 environmental management system certification, ISO45001 occupational health management system certification, measurement management system certification, intellectual property management system certification, and green enterprise management system certification.

FAQ

1. What is the principle behind the PDM Downhole Mud Motor?

The PDM Downhole Mud Motor operates on the principle of converting hydraulic energy from drilling fluid into mechanical energy to drive the drill bit.

2. How is the quality of the Downhole Mud Motor ensured?

We ensure the quality of our Downhole Mud Motors through rigorous testing and inspection processes at every stage of manufacturing. Our motors are designed to meet industry standards and undergo strict quality control measures.

3. What is the typical lead time for ordering a PDM Downhole Mud Motor?

The lead time for ordering a PDM Downhole Mud Motor may vary depending on the specific model and quantity required. Please contact our sales team for accurate lead time information.

4. How are the PDM Downhole Mud Motors transported to customers?

We have established reliable transportation channels to ensure safe and timely delivery of our PDM Downhole Mud Motors. We work with trusted logistics partners who specialize in handling sensitive equipment to ensure secure transportation.

5. What are the characteristics of your factory in terms of production?

Our factory is equipped with state-of-the-art machinery and advanced production facilities to manufacture high-quality PDM Downhole Mud Motors. We have a skilled workforce and follow strict quality control protocols to ensure efficient and reliable production processes.