Product Introduction

Introducing our High Temperature Resistant Downhole Motor, designed to withstand extreme temperatures ranging from 150-200 degrees Celsius.

Engineered with cutting-edge technology and precision, this motor is built to excel in the most demanding downhole environments.

Our High Temperature Resistant Downhole Motor is the perfect solution for oil and gas drilling operations in high-temperature wells. Its exceptional heat resistance ensures optimal performance and longevity even in the harshest conditions.

With a professional tone and unwavering reliability, this motor is your trusted partner in achieving efficient and successful drilling operations.

Invest in our High Temperature Resistant Downhole Motor today and experience unparalleled durability and performance in the most challenging downhole applications.

Product Advantage

1.Shengde High Temperature Resistant Downhole Motor can work normally downhole over 6000 meters.

2. Our High Temperature Resistant Downhole Motor can operate normally at downhole temperatures from 150ºC to 200ºC.

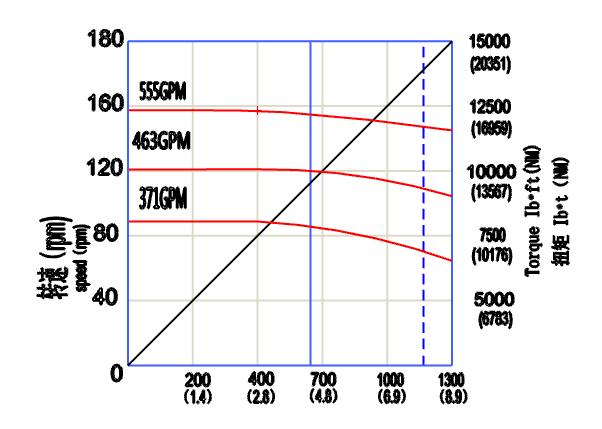

3. In addition, our High Temperature Resistant Downhole Motor also meet the requirements of customers for large displacement, which is favored by customers.

4. Our new products can work normally in the downhole more than 7000 meters and the temperature is more than 200ºC without any influence.

Product Uses

1. Oil and Gas Exploration:

This High Temperature Resistant Downhole Motor is specifically designed for use in deep wells and high-temperature wells during oil and gas exploration. In this application scenario, the motor is deployed in the downhole environment to provide reliable power and control for various drilling operations. Its high-temperature resistance ensures optimal performance and durability even in extreme heat conditions commonly encountered in deep and high-temperature wells.

2. Scientific Research and Well Logging:

The High Temperature Resistant Downhole Motor finds application in scientific research and well logging operations. In this scenario, the motor is integrated into downhole tools used to collect data and measurements from deep wells. Its high-temperature resistance enables reliable and accurate data acquisition in challenging downhole environments, facilitating scientific research, reservoir characterization, and well logging activities.

3. Enhanced Oil Recovery (EOR):

This downhole motor is extensively used in Enhanced Oil Recovery techniques, such as steam-assisted gravity drainage (SAGD) or cyclic steam stimulation (CSS). In this application scenario, the motor powers the drilling equipment required for injecting steam or other fluids into the reservoir to enhance oil recovery. Its ability to withstand high temperatures ensures uninterrupted operation in the harsh downhole conditions encountered during EOR processes.

4. Offshore Drilling:

The High Temperature Resistant Downhole Motor is well-suited for offshore drilling operations. In this scenario, the motor is employed in subsea drilling systems, providing reliable power and control for drilling activities in deepwater environments. Its high-temperature resistance and robust design ensure optimal performance and longevity, even in the challenging offshore conditions characterized by high pressures, corrosive fluids, and extreme temperatures.

In conclusion, the High Temperature Resistant Downhole Motor finds diverse applications in oil and gas exploration, geothermal energy extraction, mining and mineral exploration, scientific research, well logging, enhanced oil recovery, and offshore drilling. Its exceptional high-temperature resistance and reliability make it an indispensable component for various downhole operations, enabling efficient and successful exploration, extraction, and research activities in demanding environments.

FAQ

Q1: What is a High Temperature Resistant Downhole Motor?

A1: A High Temperature Resistant Downhole Motor is a tool used in oil and gas drilling operations that can withstand high temperatures ranging from 150-200 degrees Celsius.

Q2: What are the features of a High Temperature Resistant Downhole Motor?

A2: The High Temperature Resistant Downhole Motor is designed to operate in extreme heat conditions, making it suitable for drilling wells up to 6000 meters deep. It is built with materials that can withstand high temperatures and maintain optimal performance.

Q3: How does a High Temperature Resistant Downhole Motor help in oil and gas drilling?

A3: The High Temperature Resistant Downhole Motor provides the necessary power and torque to rotate the drill bit in high-temperature environments, enabling efficient drilling operations in challenging conditions.