Product Introduction

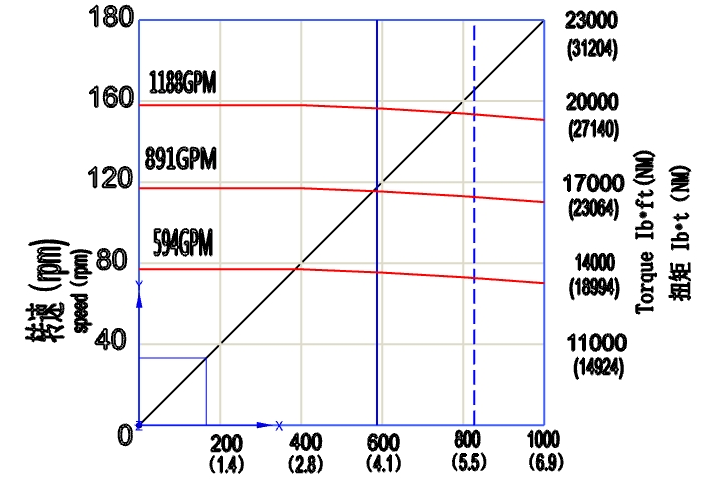

Shengde high torque Downhole Motor is a motor with super-hard rubber, making the single-stage bearing capacity of the stator higher, reaching 1.5-2MPa/class, so that the output torque to reach a higher value, its maximum torque can reach the normal screw more than 1.5 times. So the Downhole Motor can output more power under the same grade, and the bit can obtain greater rock-breaking force.Compared to other screw drilling tools, it has more torque for deeper boreholes and more complex formations.

Product Advantage

High torque screw drilling tools are downhole tools for complex well conditions with the following advantages:

- Greatly increase the torque of the screw drilling tool and the drilling pressure can be increased accordingly.

- Reduce the occurrence of pump holding and other phenomena.

- It can accurately carry out logging, directional and diagonalization.

- Widely used in deep well operation.

Product Uses

1. Oil and Gas Drilling: The high torque Downhole Motor is extensively used in the oil and gas drilling industry for various applications. This innovative product is designed to deliver exceptional torque, high displacement, low rotational speed, and superior drilling pressure. It plays a crucial role in drilling operations, enabling efficient and effective extraction of oil and gas reserves from deep beneath the earth's surface.

2. Directional Drilling: The Downhole Motor finds significant application in directional drilling, a technique used to control the trajectory and direction of the wellbore. With its high torque capabilities, this motor facilitates the drilling of deviated or horizontal wells, which are essential for maximizing production from reservoirs. Its ability to provide substantial drilling pressure ensures precise wellbore placement and accurate navigation through challenging geological formations.

3. Well Completion: During well completion, the Downhole Motor plays a vital role in the installation of casing, tubing, and other downhole equipment. Its high torque and low rotational speed characteristics enable smooth and efficient running of these components into the wellbore. This application scenario demands utmost precision and reliability, and the Downhole Motor excels in meeting these requirements, ensuring successful well completion operations.

4. Workover Operations: Workover operations involve interventions performed on existing wells to enhance or restore production. The high torque Downhole Motor proves invaluable in such scenarios, providing the necessary power and control to perform tasks like milling, fishing, reaming, and wellbore cleanouts. Its ability to deliver substantial torque and drilling pressure enables efficient removal of obstacles, debris, and obstructions from the wellbore, ensuring optimal well performance.

5. Geothermal Drilling: Geothermal drilling involves extracting heat from the earth's subsurface to generate renewable energy. The Downhole Motor finds extensive application in geothermal drilling due to its high torque, which allows for efficient drilling through hard rock formations. Its low rotational speed ensures minimal wear and tear, enhancing the motor's durability and longevity in demanding geothermal drilling environments.

FAQ

1. What is a High Torque Downhole Motor?

A High Torque Downhole Motor is a tool used in the oil and gas industry for drilling operations. It provides high torque power to rotate the drill bit and facilitate the drilling process.

2. How does a High Torque Downhole Motor improve drilling performance?

A High Torque Downhole Motor offers increased torque, allowing for faster and more efficient drilling. It enables operators to overcome challenging drilling conditions, such as hard formations or high angles, resulting in improved overall drilling performance.

3. Can you provide information about the inventory availability of the High Torque Downhole Motor?

For information regarding inventory availability of our High Torque Downhole Motor, please contact our sales team. They will be able to provide you with the most up-to-date information on stock availability.

4. What is the typical lead time for the delivery of a High Torque Downhole Motor?

The lead time for the delivery of a High Torque Downhole Motor may vary depending on factors such as quantity ordered and current demand. Please contact our sales team for specific information on lead times for your desired quantity.

5. How is the quality of the High Torque Downhole Motor ensured?

We maintain stringent quality control measures throughout the manufacturing process of our High Torque Downhole Motors. Our products undergo rigorous testing and inspection to ensure they meet industry standards and customer expectations. We are committed to delivering high-quality products that perform reliably in demanding drilling environments.