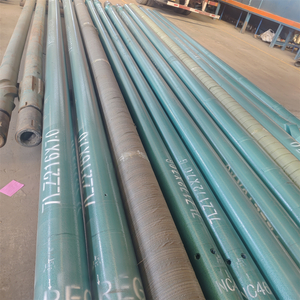

Product Introduction

The force-bearing part that supports the pressure from drilling is called the thrust bearing. This incredible bearing is designed to handle high drilling pressure and last a long time. The multi-row radial thrust ball bearing is a type of rolling bearing that can handle both axial and radial loads simultaneously. Its key characteristic is its ability to maintain high precision and rigidity even at high speeds. These bearings are commonly used in situations where both axial and radial loads need to be supported, and they play a crucial role in downhole motors.

Product Advantage

1. Shengde TC bearings display exceptional characteristics such as superb corrosion resistance, the capability to endure impacts, and a high load-carrying capacity.

2. These bearings offer an extended lifespan and demonstrate remarkable properties in reducing friction.

3. The visual and technical features of Shengde TC bearings outperform those of similar foreign products.

Product Uses

Multi-row radial thrust ball bearings are a unique type of bearings utilized in the transmission section of power drilling tools for underground drilling. These bearings typically employ a multi-row tandem design and are constructed from specialized materials. They possess a high load-bearing capacity, can withstand impacts, have a straightforward structure, and are easy to disassemble and assemble. Moreover, they are capable of enduring axial loads in both directions. These bearings are particularly suitable for applications that involve low rotational speeds, heavy loads, and intense vibrations.

FAQ

1. What is a thrust bearing and bearing assembly?

A thrust bearing and bearing assembly is a component used in downhole motors to support axial loads and facilitate smooth rotation. It consists of multiple bearings arranged in a specific configuration to handle both radial and axial forces.

2. How does a thrust bearing and bearing assembly contribute to the performance of a downhole motor?

The thrust bearing and bearing assembly play a crucial role in the overall performance of a downhole motor. They ensure proper alignment, reduce friction, and support the motor's rotating components, resulting in improved efficiency, increased torque, and extended operational lifespan.

3. What certifications does your thrust bearing and bearing assembly hold?

Our thrust bearing and bearing assembly have undergone rigorous testing and meet the highest industry standards. They are certified by recognized authorities, ensuring their quality, reliability, and compliance with relevant regulations.

4. What is the typical delivery time for your thrust bearing and bearing assembly?

Our company understands the importance of timely delivery. The typical delivery time for our thrust bearing and bearing assembly depends on various factors such as order volume, customization requirements, and shipping distance. However, we strive to provide prompt delivery and can provide specific timelines upon request.

5. What is the quality warranty period for your thrust bearing and bearing assembly?

We stand behind the quality of our thrust bearing and bearing assembly. We offer a standard warranty period to ensure customer satisfaction. The specific warranty period may vary depending on the product model and application. Please contact our customer support team for detailed information regarding the quality warranty for your specific purchase.