Product Introduction

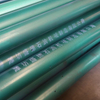

The production of Uniform Wall Thick PDM is an important technological reform. The cycloid contour of the PDM is made by special technology, so the thickness of the rubber layer on the axial section is even.

Product Advantage

1.It can avoid the accumulation effect of hysteresis heat of conventional rubber and reduce the risk of rubber damage.

2. good heat dissipation, can effectively slow down the thermal aging of stator rubber, can adapt to higher bottom-hole temperature, increase service life.

3. The thermal expansion and swelling are uniform, the rubber contour deformation of stator is small, which can effectively ensure the motor linear cooperation and improve the sealing performance. The rubber layer is uniform in thickness, and compared with the traditional stator rubber, it is close to the traditional thinnest place, so the deformation is small and the single-stage bearing capacity is high.

Product Uses

Downhole motors are widely used in directional, horizontal, clustered and straight wells in oilfields and mines for drilling, slanting, twisting, coring, reaming, windowing, sidetracking and workovers, and can be used for composite drilling and traversing, and other special operations.

Product Operate Guide

1. Ground inspection before downhole;

2. Drilling, Although the drill is simple in shape and rigid enough, it is still necessary to control the lowering speed when the drilling tool islowered, otherwise it can be easily damaged by the sand bridge,wellbore shoulder and the casing shoe in the wellbore.

3. Start-up Drilling Tool

4. Normal Drilling,In the process of drilling, to maintain the basic stability of the torque, drilling press should be as smooth as possible

5. Lifting Drills

FAQ

Q: Are you a manufacturer?

A: Yes, we are factory.

Q: How about the delivery time?

A:10-25 working days after payment.

Q:What is the warranty period of your downhole motor and can you provide maintenance service?

A:Our downhole motor have a warranty of 400 hours, we have our own repair station in Kazakhstan, and we will consider setting up a repair service station in other places if needed.