Product Introduction

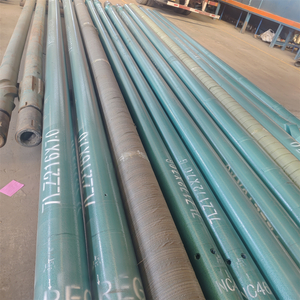

In the realm of drilling tool technology, innovative downhole motors have emerged as a remarkable equipment. The progress and utilization of these fresh downhole motors hold immense importance in enhancing the technical expertise of oil exploration and guaranteeing energy stability. Each distinct downhole motor may possess unique designs and functionalities, with specific characteristics and benefits that may differ based on product specifications.

Product Advantage

1. Enhanced torque: By implementing enhanced engineering, the newly developed screw drilling tools offer increased torque output, resulting in improved drilling efficiency and the ability to handle intricate geological conditions.

2. Streamlined drilling: By incorporating cutting-edge technology and design, it enhances drilling speed while reducing both drilling time and expenses.

3. Adaptability to extreme heat: Capable of operating reliably in high-temperature environments, it fulfills the requirements of deep-well exploration.

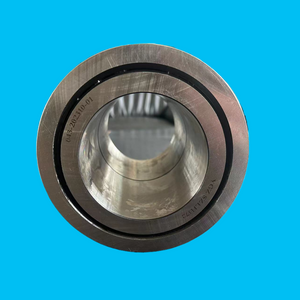

4. Exceptional durability and wear resistance: Crafted from top-notch materials, it possesses remarkable strength and resistance to wear, thus extending its lifespan.

5. Accurate command: With the integration of an advanced control system, it achieves precise control over the drilling process, thereby enhancing the overall quality of drilling.

Product Uses

In the field of oil exploration, newer downhole motors have various applications:

1. Directional drilling: This technology enables precise control of the borehole trajectory, allowing the drill bit to drill in a predetermined direction. It is particularly useful in extracting oil from complex reservoirs.

2. Horizontal well drilling: This technique is crucial for constructing horizontal wells, which are better suited for drilling in horizontal sections.

3. Deep and ultra-deep well operations: These motors are designed to withstand high temperatures and pressures, making them ideal for exploring deep and ultra-deep wells. They enhance drilling capacity in such challenging environments.

4. Complex formation drilling: In difficult geological conditions like hard rock or gravel-bearing formations, the new screw drilling tools provide stable power and improved maneuverability.

5. Side drilling operations: When drilling in existing wells, the flexible drilling performance of these motors can be utilized to open new boreholes.

6. Drilling of special wells: For instance, when drilling large displacement wells or other special types of wells, the new screw drilling tools prove highly effective.

FAQ

1. Are you a manufacturer or trading company?

Our company is a business that combines manufacturing and trading. This means that we not only produce downhole motors and related products and accessories, but also sell them domestically and internationally.

2. How do you ensure the quality of your products?

We manufacture our downhole motors according to API standards. We have always maintained strict quality control throughout the entire production process, from the raw materials to the finished products. We never allow any substandard parts to proceed to the next stage, ensuring that each downhole motor passes inspection before being delivered.

3. How can I place an order?

3.1 To place an order, our customers need to provide us with the product name, quantity, detailed specifications, packaging requirements, and any other relevant conditions. It would be helpful if they could also provide us with pictures or videos of similar products, so that we can have a clear understanding of their needs.

3.2 Based on the customer's requirements, we will provide an offer and detailed specifications for their confirmation.

3.3 Once the customer confirms the offer, we will prepare a proforma invoice (P/I) for both parties to sign and stamp.

3.4 The order will only be placed once payment has been made for the supply.