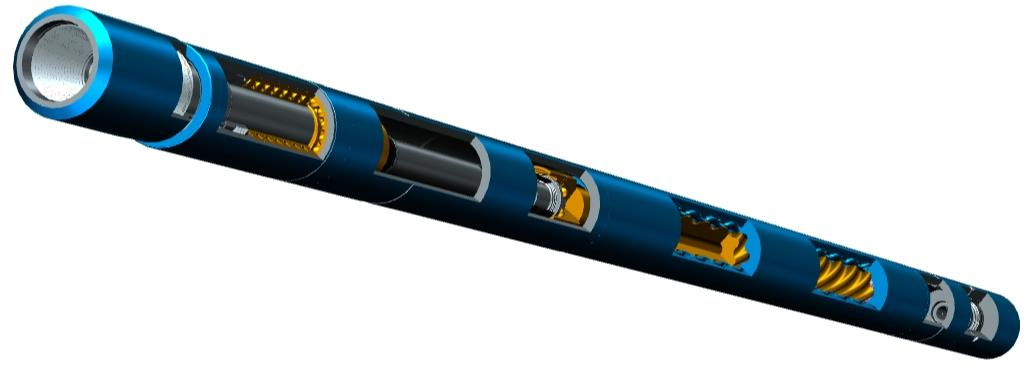

Product Introduction

Our mining downhole motors are designed with an external spiral and a three-pronged structure, which significantly improves their ability to carry rocks. This feature has been highly appreciated by our customers. Additionally, the motor power remains strong, providing a reliable torque for breaking rocks and further enhancing their carrying capacity. As a result, our motors are trusted tools for coal mine drilling.

Product Advantage

1. Specially designed screw: Utilizing a unique screw structure, such as a helix design with multiple or combined twists, to enhance the drilling bit's ability to cut through and transport rocks.

2. Powerful drive system: Equipped with a robust power drive system to deliver ample torque and speed, ensuring the drill bit effectively fractures and carries rocks.

3. Enhanced mud circulation: Through optimizing the mud circulation system, increasing the flow rate and velocity of the mud, it facilitates the swift removal of fragmented rocks from the hole.

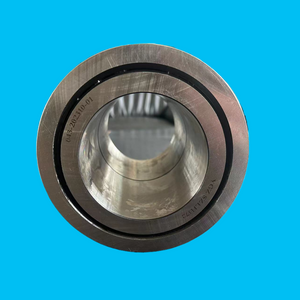

4. Durable materials and coatings: Employing wear-resistant materials for crucial components of drill bits and tools, or applying specialized coatings to enhance resistance against wear and corrosion, thereby prolonging their lifespan.

Product Uses

1. Mining Operations:

In mining operations, the Downhole Motors for Mines with Superb Rock-Carrying Capacity play a crucial role in drilling and excavation processes. These motors are specifically designed to withstand the demanding conditions encountered in mines. With their exceptional rock-carrying capacity, they enable efficient drilling and excavation by effectively transporting rocks and debris to the surface. The motors' high displacement mud circulation capability ensures smooth and uninterrupted drilling operations, even in high-volume mud circulation scenarios. Additionally, their outstanding wear resistance ensures prolonged durability, reducing downtime and maintenance costs in mining operations.

2. Oil and Gas Exploration:

The Downhole Motors for Mines with Superb Rock-Carrying Capacity find extensive application in oil and gas exploration activities. These motors are utilized in directional drilling, where precise control and maneuverability are essential. With their powerful rock-carrying capacity, they effectively transport rock cuttings and drilling fluids to the surface, ensuring uninterrupted drilling operations. The motors' ability to handle high mud circulation rates is particularly advantageous in oil and gas exploration, where large volumes of drilling fluids need to be circulated. Furthermore, their exceptional wear resistance enables them to withstand the abrasive conditions encountered in drilling deep into the earth's crust.

3. Geothermal Drilling:

Geothermal drilling involves extracting heat from the earth's interior for various applications. The Downhole Motors for Mines with Superb Rock-Carrying Capacity play a vital role in geothermal drilling operations. These motors excel in transporting rocks and cuttings to the surface, ensuring efficient drilling progress. Their ability to handle high mud circulation rates is crucial in geothermal drilling, where effective heat transfer requires continuous circulation of drilling fluids. Moreover, the motors' exceptional wear resistance ensures longevity, reducing the need for frequent replacements and minimizing downtime in geothermal drilling projects.

4. Construction and Tunneling:

In construction and tunneling projects, the Downhole Motors for Mines with Superb Rock-Carrying Capacity offer significant advantages. These motors are employed in drilling and excavation tasks, where their exceptional rock-carrying capacity proves invaluable. By efficiently transporting rocks and debris to the surface, they facilitate smooth and productive drilling operations. The motors' high displacement mud circulation capability enables effective mud circulation in construction and tunneling projects, ensuring the stability and integrity of the drilled structures. Additionally, their outstanding wear resistance ensures prolonged durability, minimizing maintenance requirements and enhancing overall project efficiency.

5. Water Well Drilling:

Water well drilling requires reliable and efficient drilling equipment to access underground water sources. The Downhole Motors for Mines with Superb Rock-Carrying Capacity find application in water well drilling due to their exceptional performance characteristics. These motors excel in transporting rocks and cuttings to the surface, enabling efficient drilling progress. Their ability to handle high mud circulation rates is particularly advantageous in water well drilling, where continuous circulation of drilling fluids is necessary for effective drilling and well completion. Furthermore, the motors' outstanding wear resistance ensures longevity, reducing downtime and maintenance costs in water well drilling operations.

FAQ

Q: We require additional information regarding your technology.

A: I will forward you our comprehensive company profile and details.

Q: What is your method for ensuring quality control?

A: We implement a rigorous quality control system to guarantee the production of top-notch goods.

Q: Can you provide evidence of your export activities?

A: Our products have been successfully marketed in various international regions and have gained significant popularity among users there.

Q: Does the price mentioned in the quotation reflect the actual price?

A: Yes, however, please note that it is subject to change based on time constraints.