Product Introduction

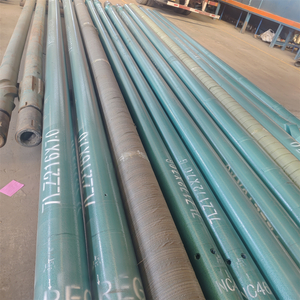

The saltwater mud drilling motor assembly is a tool that converts the power from the pressurized drilling fluid into mechanical energy. This energy is utilized to spin the spindle and drill bit via the rotor, enabling drilling to occur. The drilling fluid usually consists of salt-based ions, and the rotor is shielded with tungsten carbide to prevent damage from the mud.

Product Advantage

1. With over 30 years of experience, we specialize in producing Downhole motors.

2. Our factory is outfitted with cutting-edge manufacturing equipment like CNC spiral milling machines and 1000-ton injection molding presses.

3. We provide a range of rubber compound choices, including standard, oil-resistant, and high-temperature options.

4. Our rotors are protected with anti-corrosion coatings such as chromium plating, salt-resistant tungsten carbide, and nickel plating.

5. The thread connections on our items can be customized to suit the specific requirements of our clients.

Product Uses

The saltwater mud motor is mainly used for operations below ground. In deep wells with hard rock formations, there is a lot of pressure at the bottom of the hole. To address this, saltwater mud containing chloride ions is often used as the drilling fluid to avoid leaks and keep the pressure stable.

FAQ

1. What is a Saturated Brine Mud Downhole Motor Assembly used for in the oil and gas industry?

- A Saturated Brine Mud Downhole Motor Assembly is used to provide power and torque to drill bits in drilling operations in challenging downhole conditions.

2. How does the quality of the Downhole Motor Assembly impact drilling performance?

- The quality of the Downhole Motor Assembly directly affects the efficiency and reliability of drilling operations, as it determines the power and speed at which the drill bit can operate.

3. Can I request a trial sample of the Saturated Brine Mud Downhole Motor Assembly before making a purchase?

- Yes, we offer trial samples of our Downhole Motor Assemblies for testing and evaluation purposes to ensure they meet your specific requirements.

4. Are there any warranty options available for the Saturated Brine Mud Downhole Motor Assembly?

- Yes, we provide a warranty period for our Downhole Motor Assemblies to guarantee their performance and quality, ensuring customer satisfaction.

5. Do you have stock available for immediate delivery at your service stations?

- Yes, we maintain a stock of Saturated Brine Mud Downhole Motor Assemblies at our service stations for quick and convenient delivery to meet our customers' needs.