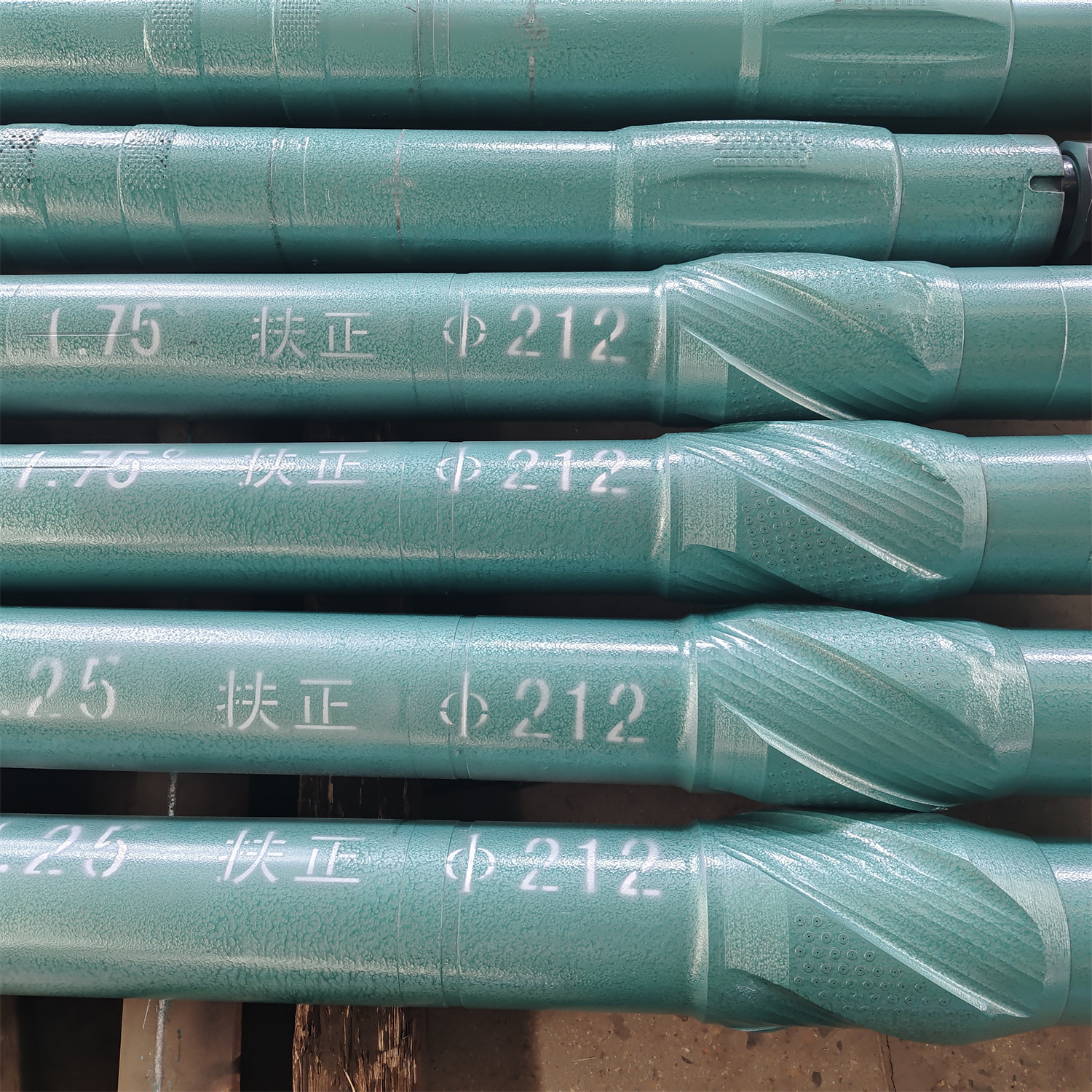

Product Introduction

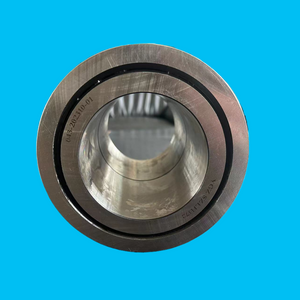

The main part of the bottom hole assembly (BHA) that enables efficient and accurate drilling operations is the drilling motor. These motors, which are highly efficient, generate rotational force to power the drill bit. With advanced technology and excellent design, drilling motors provide improved torque, speed, and dependability.

The drilling motor is a type of motor known as a positive displacement motor (PDM). The motor receives high-pressure drilling fluid, which converts the fluid's power into mechanical energy. The rotor then drives the shaft and causes the bit to rotate. We have the capability to produce drilling motors for hole sizes ranging from 1 7/8" to 26". Additionally, we can customize and manufacture drilling motors according to the specific requirements of our customers.

Product Advantage

1. Every drilling motor is furnished with a rotor capture sub;

2. Drilling motors have the option to be furnished with a buoyant upper sub, discharge sub, or exclusive capture sub;

3. Drilling motors are compatible with both water-based mud (WBM) and oil-based mud (OBM);

4. Fitted with adjustable housings ranging from 0 to 3°;

5. Screw-on stabilizers, fixed stabilizers, or blank stabilizers are all available;

6. Enhanced bearing mandrel designed for high torque power sections.

Product Uses

1. Mining Operations:

In mining operations, the Downhole Motors for Mines with Superb Rock-Carrying Capacity play a crucial role in drilling and excavation processes. These motors are specifically designed to withstand the demanding conditions encountered in mines. With their exceptional rock-carrying capacity, they enable efficient drilling and excavation by effectively transporting rocks and debris to the surface. The motors' high displacement mud circulation capability ensures smooth and uninterrupted drilling operations, even in high-volume mud circulation scenarios. Additionally, their outstanding wear resistance ensures prolonged durability, reducing downtime and maintenance costs in mining operations.

2. Oil and Gas Exploration:

The Downhole Motors for Mines with Superb Rock-Carrying Capacity find extensive application in oil and gas exploration activities. These motors are utilized in directional drilling, where precise control and maneuverability are essential. With their powerful rock-carrying capacity, they effectively transport rock cuttings and drilling fluids to the surface, ensuring uninterrupted drilling operations. The motors' ability to handle high mud circulation rates is particularly advantageous in oil and gas exploration, where large volumes of drilling fluids need to be circulated. Furthermore, their exceptional wear resistance enables them to withstand the abrasive conditions encountered in drilling deep into the earth's crust.

3. Geothermal Drilling:

Geothermal drilling involves extracting heat from the earth's interior for various applications. The Downhole Motors for Mines with Superb Rock-Carrying Capacity play a vital role in geothermal drilling operations. These motors excel in transporting rocks and cuttings to the surface, ensuring efficient drilling progress. Their ability to handle high mud circulation rates is crucial in geothermal drilling, where effective heat transfer requires continuous circulation of drilling fluids. Moreover, the motors' exceptional wear resistance ensures longevity, reducing the need for frequent replacements and minimizing downtime in geothermal drilling projects.

4. Construction and Tunneling:

In construction and tunneling projects, the Downhole Motors for Mines with Superb Rock-Carrying Capacity offer significant advantages. These motors are employed in drilling and excavation tasks, where their exceptional rock-carrying capacity proves invaluable. By efficiently transporting rocks and debris to the surface, they facilitate smooth and productive drilling operations. The motors' high displacement mud circulation capability enables effective mud circulation in construction and tunneling projects, ensuring the stability and integrity of the drilled structures. Additionally, their outstanding wear resistance ensures prolonged durability, minimizing maintenance requirements and enhancing overall project efficiency.

5. Water Well Drilling:

Water well drilling requires reliable and efficient drilling equipment to access underground water sources. The Downhole Motors for Mines with Superb Rock-Carrying Capacity find application in water well drilling due to their exceptional performance characteristics. These motors excel in transporting rocks and cuttings to the surface, enabling efficient drilling progress. Their ability to handle high mud circulation rates is particularly advantageous in water well drilling, where continuous circulation of drilling fluids is necessary for effective drilling and well completion. Furthermore, the motors' outstanding wear resistance ensures longevity, reducing downtime and maintenance costs in water well drilling operations.

FAQ

Are you a manufacturer that operates a factory?

Yes, we are a factory manufacturer with the ability to produce a large quantity of goods while ensuring their quality. We have our own team of technical engineers and production facilities, which allows us to offer customers tools and equipment related to the petroleum industry that are both high-quality and affordable.

What is your procedure for handling my inquiry?

Initially, we will communicate with you via email or TM to discuss the details of your order and the production process. Subsequently, we will provide you with a Proforma Invoice (PI) for your confirmation. Before we begin production, we will require you to make a full payment or deposit. If the items are not in stock, it typically takes us 7-15 days to complete the production. Prior to finishing production, we will contact you to arrange the shipment and discuss the remaining payment. Once the payment has been settled, we will prepare the shipment for you.

How can I make payment for the order?

Once you have confirmed our PI, we will request payment from you. The most common payment methods we accept are T/T, L/C, D/P, and Western Union. However, we are open to discussing other payment methods that are convenient for you.