Product Introduction

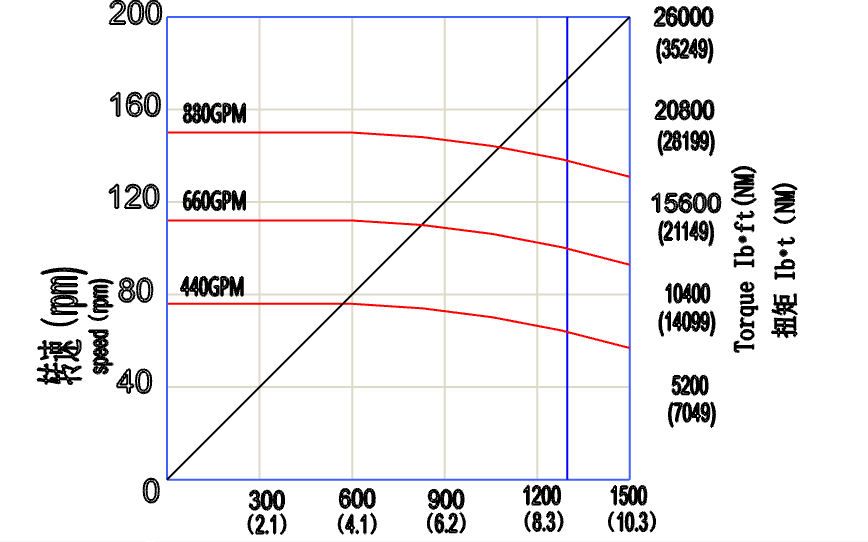

Isobaric screw drilling tools are a kind of tools used for oil drilling. Isobaric screw drilling tools have the following advantages: fast drilling speed, high adaptability, high reliability and high torque.

The use of equal wall thickness downhole motor needs to be selected according to the specific well conditions and drilling requirements to ensure that they can play the best performance.

Product Advantage

- Fast drilling speed: the gap between the rotor and stator of the equal wall thickness screw drilling tools is small, which can increase the drilling speed.

- Strong adaptability: equal wall thickness screw drilling tools can be adapted to different borehole diameters and depths, with a wide range of applications.

- High reliability: the structure of equal wall thickness screw drilling tools is simple, high reliability and long service life.

- Large torque: The large torque of equal wall thickness screw drilling tools can improve drilling efficiency.

Product Uses

Equal wall thickness downhole motor are mainly used in the drilling and extraction of oil, natural gas and other resources.

Equal wall thickness downhole motor have unique advantages in directional wells, horizontal wells, deep wells and other complex well conditions, which can effectively improve drilling speed and efficiency and reduce drilling costs. In addition, equal wall thickness downhole motor can also be used in the fields of geological exploration, mining, construction and foundation engineering.

FAQ

1. What is an equal wall thickness downhole motor?

An equal wall thickness downhole motor is a type of drilling tool used in the oil and gas industry. It features a uniform thickness throughout its structure, providing enhanced durability and performance.

2. How does an equal wall thickness downhole motor work?

The equal wall thickness downhole motor operates by converting hydraulic power from drilling fluid into mechanical power. This rotational power is then used to drive the drill bit, enabling the drilling process in oil and gas wells.

3. Which certifications does your company hold for the equal wall thickness downhole motor?

Our company holds various certifications for the equal wall thickness downhole motor, ensuring its quality and compliance with industry standards. Some common certifications include ISO 9001 and API 7-1.

4. What is the minimum order quantity for the equal wall thickness downhole motor?

The minimum order quantity for the equal wall thickness downhole motor may vary depending on the specific product model and company policies. Please contact our sales team for detailed information regarding the minimum order quantity.

5. Can you provide information about your company's certification system for the equal wall thickness downhole motor?

Our company maintains a comprehensive certification system for the equal wall thickness downhole motor. This system ensures that our products meet the required quality standards and adhere to industry regulations. We continuously strive to improve our certification system to provide reliable and high-performing drilling tools.