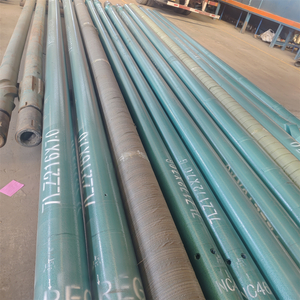

Product Introduction

The equal thickness downhole motor is the main component that provides power for the screw drilling tool. It offers several benefits such as consistent and balanced deformation, effective sealing, high torque per unit length, and efficient heat dissipation. These advantages play a crucial role in slowing down the deterioration of the rubber and extending the overall lifespan of the tool.

Product Advantage

1. Even force distribution: The uniform deformation of equal wall thickness screw drilling tools ensures that the entire tool is subjected to force evenly, reducing the risk of damage from localized force and extending its lifespan.

2. Enhanced sealing ability: The sealing structure of equal wall thickness screw drilling tools is simpler yet more effective, preventing mud leakage and improving drilling efficiency.

3. Increased torque per unit length: The longer screw length of equal wall thickness screw drilling tools provides higher torque per unit length, resulting in improved drilling speed and efficiency.

4. Efficient heat dissipation: Equal wall thickness screw drilling tools have a larger surface area for heat dissipation, effectively reducing the temperature of the tools and minimizing damage caused by high temperatures.

5. Delayed rubber aging: The thicker rubber component of equal wall thickness screw drilling tools slows down the aging process, prolonging the tool's lifespan.

Product Uses

Equal wall thickness Downhole motors have become increasingly popular in the oil drilling industry. These innovative motors have proven to be highly beneficial in enhancing drilling speed and efficiency, minimizing downtime caused by damage, and ultimately improving economic returns. Furthermore, their versatility extends beyond oil drilling, as they can also be utilized in various other sectors including geological exploration and engineering drilling.

FAQ

1. What is an equal wall thickness downhole motor assembly?

- An equal wall thickness downhole motor assembly is a type of motor used in drilling operations that ensures consistent wall thickness throughout its structure. This design feature enhances the motor's durability and performance.

2. How does the equal wall thickness downhole motor assembly improve drilling operations?

- The equal wall thickness design of this motor assembly ensures uniform distribution of stress and load, resulting in improved drilling efficiency and reduced downtime. It offers better stability and control during drilling operations.

3. What are the available payment methods for purchasing the equal wall thickness downhole motor assembly?

- We offer various payment methods, including credit card payments, bank transfers, and PayPal. Please contact our sales team for more information on payment options and to discuss your specific requirements.

4. What is the typical delivery time for the equal wall thickness downhole motor assembly?

- Our standard delivery time for the equal wall thickness downhole motor assembly is typically X days. However, this may vary depending on factors such as order volume and customization requirements. Please reach out to our sales team for a more accurate estimate based on your specific needs.

5. Can you provide information about the quality system and certifications for the equal wall thickness downhole motor assembly?

- Our equal wall thickness downhole motor assembly is manufactured according to stringent quality standards and is certified to meet industry regulations. We have implemented a robust quality management system to ensure consistent product quality and customer satisfaction. Please let us know if you require specific details or certifications for your project.