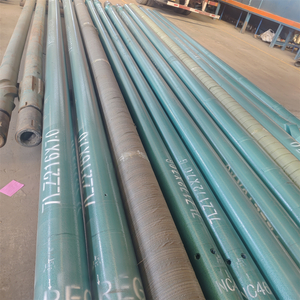

Product Introduction

Equal wall thickness downhole motor is the power part of the screw drilling tool. Equal wall thickness downhole motor has the advantages of uniform force deformation, good sealing performance, large torque per unit length, good heat dissipation performance, etc., which is helpful for slowing down the aging of the rubber and prolonging the service life.

Product Advantage

1. Uniform deformation by force: Since the thickness of each part of equal wall thickness screw drilling tools is equal, the deformation of the whole drilling tool is more uniform when it is subjected to force, which can reduce the damage caused by uneven local force and prolong the service life.

2. Good sealing performance: The sealing structure of equal wall thickness screw drilling tools is simpler and the sealing effect is better, which can effectively prevent mud leakage and improve drilling efficiency.

3. Higher torque per unit length: The screw length of the equal wall thickness screw drilling tools is longer, which provides higher torque per unit length, thus improving drilling speed and efficiency.

4. Good heat dissipation: Equal wall thickness screw drilling tools have a larger heat dissipation area and better heat dissipation effect, which can effectively reduce the temperature of the drilling tools and minimize the damage caused by high temperature.

5. Slow down the aging of rubber: The rubber part of the equal wall thickness screw drilling tools is thicker, which can slow down the aging of rubber and prolong the service life.

Product Uses

As a new type of Downhole motor, equal wall thickness Downhole motors are widely used in oil drilling construction process. In practical application, equal-wall-thickness Downhole motors can effectively improve drilling speed and efficiency, reduce downtime due to damage, and improve economic efficiency. In addition, equal wall thickness Downhole motors can also be used in other fields, such as geological exploration, engineering drilling and so on.

FAQ

1. What is an equal wall thickness downhole motor?

An equal wall thickness downhole motor is a type of motor used in drilling operations that maintains a consistent thickness throughout its structure.

2. What are the advantages of using an equal wall thickness downhole motor?

Using an equal wall thickness downhole motor offers several advantages, including improved stability, enhanced durability, and increased efficiency in drilling operations.

3. What materials are commonly used in the construction of equal wall thickness downhole motors?

Equal wall thickness downhole motors are typically constructed using high-quality materials such as steel, aluminum, and other alloys known for their strength and resistance to harsh drilling conditions.

4. How does the rubber performance of an equal wall thickness downhole motor impact its overall performance?

The rubber performance of an equal wall thickness downhole motor plays a crucial role in its overall performance. It affects factors such as vibration reduction, sealing capabilities, and resistance to wear and tear.

5. Are there any certifications or certificates associated with equal wall thickness downhole motors?

Yes, equal wall thickness downhole motors may have certifications or certificates that validate their quality and compliance with industry standards. It is important to inquire about these certifications when purchasing or using such motors.