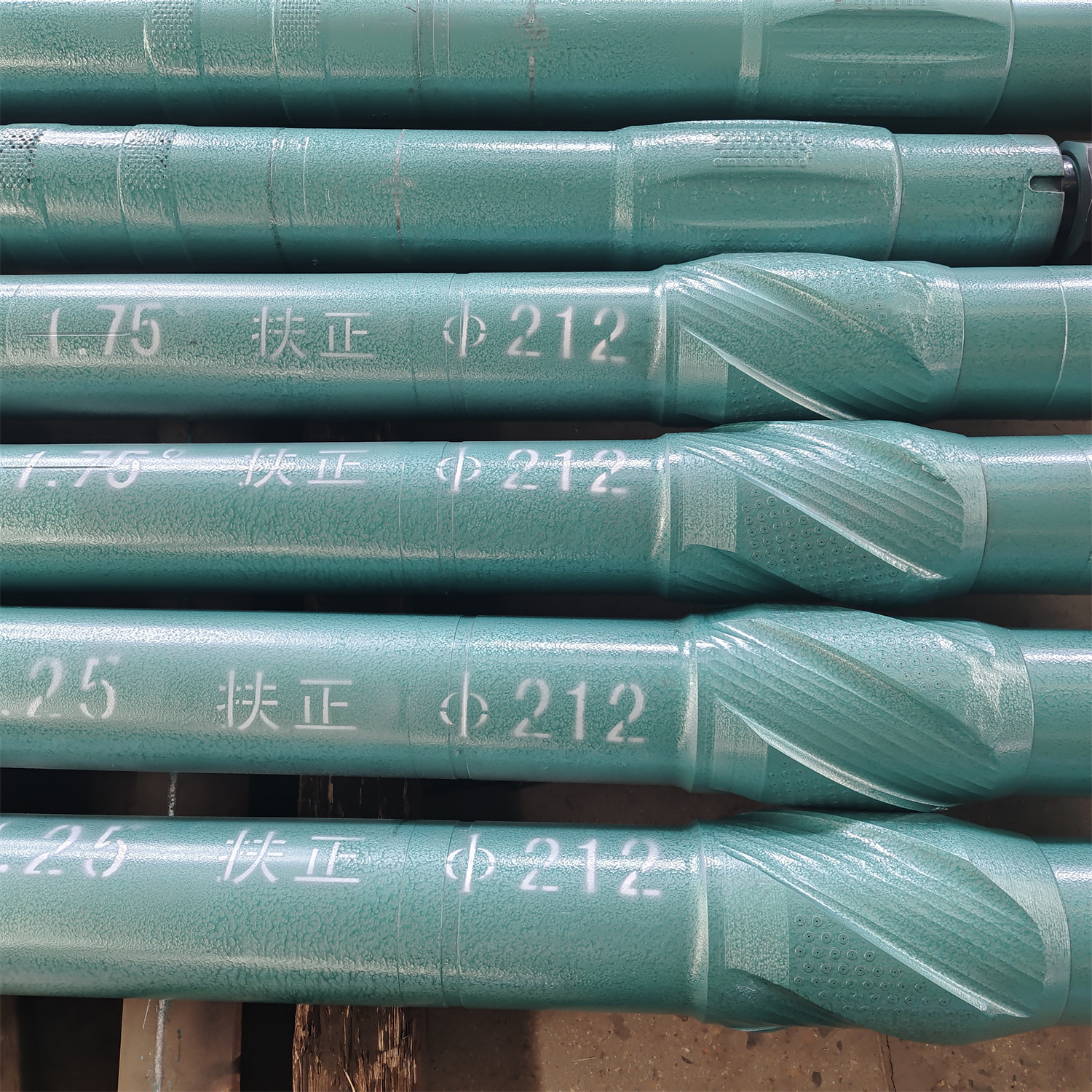

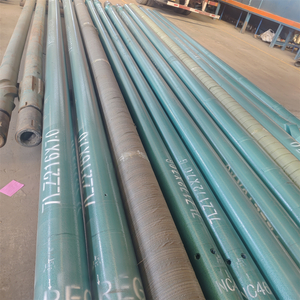

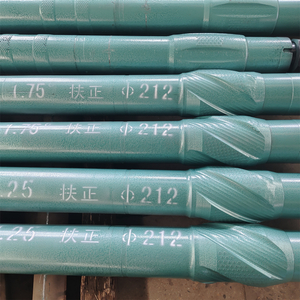

Product Introduction

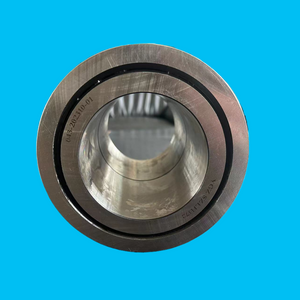

A downhole motor is a tool used in drilling that converts the energy of drilling fluid into mechanical power. When the mud pump supplies mud to the motor, the pressure changes at the motor's entry and exit points, causing the rotor to rotate around the center of the stator. This rotation transfers torque and speed to the drill bit through a universal shaft and transmission shaft, allowing drilling operations. Downhole motors are widely used in drilling and maintenance tasks in oilfields and coal mines.

Product Advantage

The benefits of using screw drilling tools for directional drilling are as follows:

1. Enhanced drilling efficiency: By increasing the number of bit revolutions and torque, screw drilling tools can improve the feed rate and shorten the drilling cycle.

2. Reduced wear and damage: Direct power supply from the well bottom minimizes wear and damage to the drill pipe.

3. Precise orientation: Screw drilling tools enable accurate orientation, slope adjustment, and deviation correction, leading to improved economic efficiency in horizontal wells, clustered wells, and well workover operations.

4. Prolonged tool lifespan: The advanced structure of screw drilling tools enhances their durability, resulting in a longer lifespan.

5. Adaptability to complex geological conditions: Screw drilling tools are particularly effective in challenging geological conditions, such as high rock hardness and steep formation angles, thereby increasing the drilling success rate.

Product Uses

The screw drilling device for directional drilling is an advanced tool with a wide range of applications:

1. Directional drilling: This tool enables simultaneous adjustments to the drilling top angle and azimuth angle, improving precision in hitting the target. It is suitable for various types of strata and can be used in geological exploration, oil extraction, and other industries.

2. Real-time measurement: When paired with directional drillers and single-point directional drillers, it can provide real-time measurements of drilling direction and angle. This allows for prompt adjustments to the drilling trajectory, enhancing efficiency and quality.

3. Specialized drilling operations: In challenging geological conditions such as horizontal wells and branch wells, the screw drilling tool offers better adaptability and increases the success rate of drilling.

4. Improved drilling efficiency: By increasing the number of revolutions and torque of the drill bit, the drilling speed can be enhanced, resulting in shorter drilling cycles and reduced costs.

5. Minimized wear and damage: With its advanced structure, this tool effectively reduces wear and damage to the drilling equipment.

FAQ

1. What is HDD directional drilling and how does it relate to the PDM downhole motor?

- HDD directional drilling is a method used to drill horizontal or directional wells. The PDM downhole motor is a crucial component in this process, providing the necessary power and torque to steer the drill bit.

2. How does the PDM downhole motor enhance the efficiency of HDD directional drilling?

- The PDM downhole motor is specifically designed for HDD directional drilling applications. It offers high torque output, allowing for better control and steering capabilities, resulting in improved drilling efficiency and accuracy.

3. What are the advantages of using a PDM downhole motor in horizontal and directional wells?

- The PDM downhole motor offers several advantages, including increased drilling speed, reduced drilling costs, improved wellbore quality, and enhanced drilling flexibility. Its robust design and high power output make it ideal for challenging drilling conditions.

4. Can the PDM downhole motor be used in both horizontal and directional drilling applications?

- Yes, the PDM downhole motor is versatile and can be used in both horizontal and directional drilling applications. Its design allows for easy adaptability to various drilling requirements, making it suitable for a wide range of well profiles.

5. How does the PDM downhole motor compare to other types of motors used in HDD directional drilling?

- The PDM downhole motor is widely recognized for its superior performance in HDD directional drilling. Compared to other motor types, it offers higher torque output, better durability, and improved steering capabilities, making it a preferred choice among drilling professionals.