Product Introduction

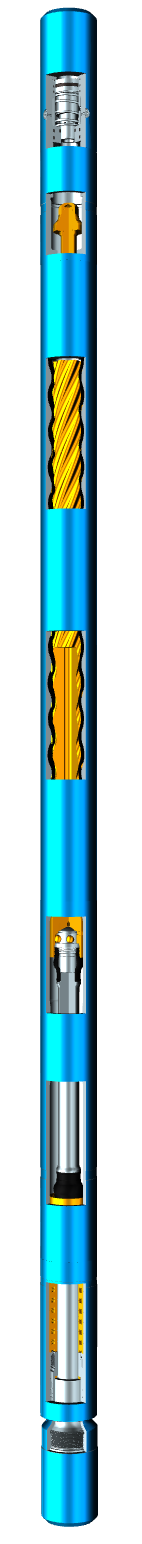

Introducing our Mud Motor with Oil Resistance Mud, designed to tackle the toughest drilling challenges with ease.

Crafted with a cutting-edge rubber formula, this motor is specifically engineered to combat the corrosive effects of aromatic hydrocarbons and other oil-based ions found in mud.

With its exceptional resistance to degradation, our mud motor ensures long-lasting performance and durability, even in the harshest drilling conditions.

Equipped with advanced technology and precision engineering, this motor delivers unparalleled power and efficiency, allowing for seamless operations and increased productivity on the job site.

Trust in our mud motor with oil resistance mud to provide the reliability and performance you need to conquer any drilling project. Invest in quality and experience the difference today.

Product Advantage

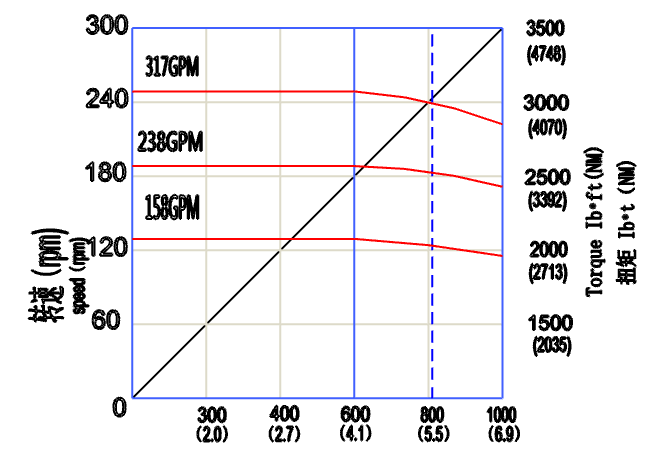

1. Enhancing the stator rubber's firmness, as well as its physical and mechanical characteristics, will increase the torque produced by the Downhole Motor.

2. The stator rubber exhibits reduced responsiveness to aromatic hydrocarbons, minimizing the risk of premature rubber expansion and subsequent stator deformities and failures. Consequently, the Downhole Motor's lifespan is significantly prolonged.

3. The stator rubber is capable of withstanding the corrosive nature of oil-based slurries, while also meeting the necessary criteria for the utilization of water-based slurries.

Product Uses

1. Oil and Gas Drilling Application Scenario:

In the oil and gas drilling industry, the Mud motor plays a crucial role in enhancing the drilling process. This high-performance tool is primarily utilized in directional drilling operations, where it provides the necessary power and torque to drill through various rock formations. With its advanced design and efficient functionality, the Mud motor ensures accurate wellbore placement and facilitates the extraction of oil and natural gas reserves.

2. Coal Mining Exploration and Extraction Application Scenario:

The Mud motor finds significant application in coal mining exploration and extraction activities. In this scenario, the product is employed to penetrate the earth's crust and reach the coal seams for mining purposes. By utilizing the Mud motor's exceptional power and rotational capabilities, miners can efficiently drill through challenging rock formations, ensuring a productive and safe mining process. This application scenario highlights the Mud motor's versatility and reliability in the demanding coal mining industry.

3. Non-Excavation Engineering Application Scenario:

The Mud motor also finds extensive application in non-excavation engineering projects. This scenario involves various construction activities that require underground drilling without the need for extensive digging or excavation. The Mud motor's exceptional power, torque, and maneuverability enable precise drilling in urban areas, congested spaces, or environmentally sensitive locations. This application scenario showcases the Mud motor's ability to minimize disruptions, reduce environmental impact, and enhance the efficiency of non-excavation engineering projects.

FAQ

Q: How can order the products without any acknowledge of import ?

A:We could arrange you shipping or air or express for you and deliver everything to your port or provide you door to door service.

Q: Can we have our Logo or company name to be printed on your products or package?

A:Sure. Your Logo could be printed on your products by Hot Stamping, Printing, Embossing, UV Coating, Silk-screen Printing or Sticker.

Q: How much the transportation freight ?

A:The freight depends on the weight and packing size and destination from here to your location