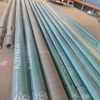

Product Introduction

This professional-grade product has been meticulously engineered to enhance drilling efficiency and ensure seamless operations in the most demanding environments. With its advanced features, our Anti-friction Downhole Motor sets a new standard in the industry.

Equipped with state-of-the-art technology, this motor effectively minimizes friction, providing a smooth and continuous drilling experience. By eliminating the risk of pressure loss, it guarantees optimal performance, saving valuable time and resources for your operations.

Our Anti-friction Downhole Motor is built to withstand the harshest conditions, making it a reliable choice for even the most challenging drilling projects. Its durability and robust construction ensure long-lasting performance, reducing downtime and maintenance costs.

With a focus on precision and reliability, this motor offers exceptional control and stability during drilling operations. Its innovative design allows for precise steering and maneuverability, enabling operators to achieve accurate results with ease.

Product Advantage

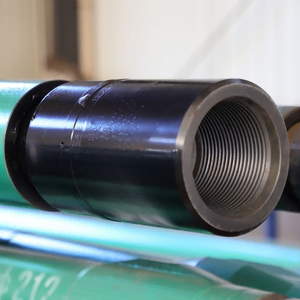

1. A stabilizer for reducing pressure in screw drilling tools, positioned on the outer part of the drive shaft of a screw drilling tool. It consists of a casing body with raised main correcting bar ridges along the outer circumference, and secondary correcting bar ridges symmetrically placed on either side of the main correcting bar ridges.

2. The anti-dislodgement grooves are positioned symmetrically in the middle of the main righting bar prongs, and there are two secondary righting bar prongs.

3. The main correcting bar prongs have a greater thickness in the middle along the axial direction compared to the ends, and the vice-correcting bar prongs also have a greater thickness in the middle along the axial direction compared to the ends. Both the main correcting bar prong and the secondary correcting bar prong are attached to the casing body as a single unit.

Product Uses

Product Application Scenarios:

1. Drilling in Hard Rock Formation:

In this scenario, the Anti-friction Downhole Motor is utilized to prevent the occurrence of pressure drop while drilling in hard rock formations. The motor is specifically designed to withstand the high torque and axial loads encountered during drilling operations in such formations. By effectively reducing friction and enhancing the performance of the drilling equipment, the motor ensures a smooth and uninterrupted drilling process, thereby improving overall drilling efficiency.

2. Directional Drilling:

The Anti-friction Downhole Motor finds extensive application in directional drilling operations. When drilling in a curved or deviated wellbore, the motor plays a crucial role in maintaining the desired trajectory and achieving accurate well placement. By providing precise control and maneuverability, the motor enables the drilling team to navigate through complex geological formations, avoiding obstacles and optimizing the wellbore path. This application scenario showcases the exceptional performance of the motor in enhancing drilling accuracy and achieving desired wellbore profiles.

3. Extended Reach Drilling:

In scenarios involving extended reach drilling, where the wellbore length exceeds conventional limits, the Anti-friction Downhole Motor proves to be a reliable solution. The motor's advanced design and construction allow it to withstand the increased mechanical stresses and drilling challenges associated with extended reach wells. By mitigating the risk of pressure drop and ensuring smooth drilling operations, the motor enables the drilling team to reach greater depths and access reserves that were previously considered inaccessible. This application scenario highlights the product's capability to support extended reach drilling projects and maximize reservoir exploitation.

4. Underbalanced Drilling:

Underbalanced drilling refers to a technique where the wellbore pressure is maintained lower than the formation pressure, minimizing damage to the reservoir and enhancing production rates. The Anti-friction Downhole Motor is an essential component in underbalanced drilling applications. By effectively preventing pressure drop and maintaining constant drilling pressure, the motor ensures the integrity of the wellbore and facilitates efficient drilling in underbalanced conditions. This application scenario demonstrates the product's significance in optimizing drilling operations and maximizing well productivity.

5. Geothermal Drilling:

The Anti-friction Downhole Motor finds application in geothermal drilling, where the objective is to tap into the earth's natural heat for energy generation. Geothermal drilling involves drilling deep into the earth's crust, encountering high temperatures and challenging geological formations. The motor's ability to withstand extreme conditions and provide reliable torque and power transmission makes it an ideal choice for geothermal drilling operations. By effectively preventing pressure drop and enhancing drilling efficiency, the motor contributes to the successful extraction of geothermal energy, supporting sustainable energy generation.

FAQ

1.Q: Are you a manufacturer? Please contact us for more information.

A: Yes, we are a factory.

2. Q: What’s minimum quantity of an order of your goods?

A: Minimum order quantity is 1 set.

3. Q: How long does it usually take you to make delivery?

A: Freight time depends on the specific situation

4. Q: What's your main port of call?

A: Our company is the closest to Qingdao port, and we can also choose according to your needs.