Product Introduction

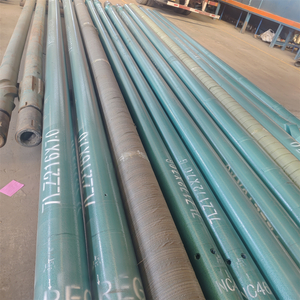

The saltwater mud drilling motor assembly is a device that changes the energy from the high-pressure drilling fluid into mechanical energy. This energy is used to rotate the spindle and drill bit through the rotor, allowing for drilling to take place. The drilling fluid typically contains salt-based ions, and the rotor is coated with tungsten carbide to protect against corrosion from the mud.

Product Advantage

1. With more than three decades of expertise, our focus is on manufacturing Downhole motors.

2. Our facility is equipped with state-of-the-art production machinery such as CNC spiral milling machines and 1000-ton injection molding presses.

3. We offer various rubber compound options, including standard, oil-resistant, and high-temperature varieties.

4. Our rotors are coated with corrosion-resistant materials like chromium plating, salt-resistant tungsten carbide, and nickel plating.

5. The thread connections on our products can be tailored to meet the specific needs of our customers.

Product Uses

The saltwater mud motor is primarily utilized in downhole operations. In deep wells with tough rock formations, there is high pressure at the bottom of the hole. To counteract this, saltwater mud with chloride ions is commonly used as the drilling fluid to prevent leaks and maintain pressure.

FAQ

1. What is a Saturated Brine Mud Downhole Motor Assembly?

A Saturated Brine Mud Downhole Motor Assembly is a specialized tool used in drilling operations to provide power and torque to the drill bit in challenging drilling environments where saturated brine mud is present.

2. How does a Downhole Motor Assembly differ from other drilling tools?

A Downhole Motor Assembly is specifically designed to operate in high-pressure, high-temperature, and abrasive drilling conditions, making it ideal for use in challenging drilling environments such as those where saturated brine mud is present.

3. Can you provide more information on the factory nature of the Saturated Brine Mud Downhole Motor Assembly?

Our factory produces high-quality Downhole Motor Assemblies using state-of-the-art manufacturing processes and quality control measures to ensure reliability and performance in demanding drilling applications.

4. What is the pricing structure for the Saturated Brine Mud Downhole Motor Assembly?

The pricing for our Saturated Brine Mud Downhole Motor Assembly varies based on specifications, quantity, and customization requirements. Please contact us for a personalized quote.

5. What is the typical lead time for delivery of the Saturated Brine Mud Downhole Motor Assembly?

Our lead times for the Saturated Brine Mud Downhole Motor Assembly depend on current production schedules and order volume. We strive to meet our customers' delivery requirements and can provide estimated delivery times upon request.