Product Introduction

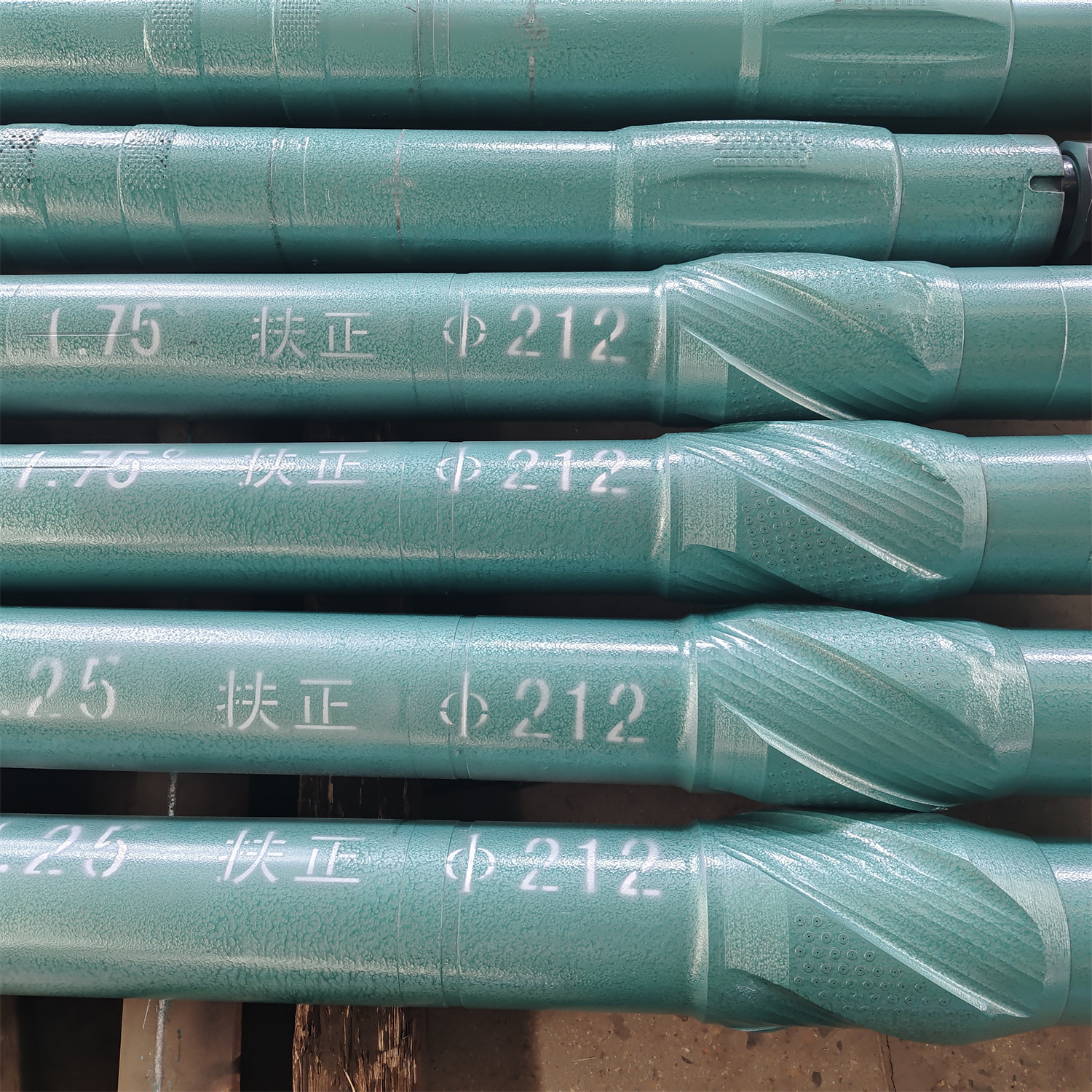

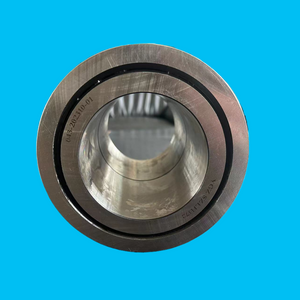

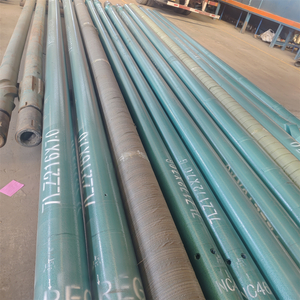

A downhole motor is a device utilized in drilling that utilizes the force of drilling fluid to transform liquid pressure into mechanical power. When the mud pump delivers mud to the motor, the pressure alters at the motor's entry and exit points, resulting in the rotor spinning around the stator's center. This spinning motion then transmits torque and speed to the drill bit through a universal shaft and transmission shaft, enabling drilling operations. Downhole motors are extensively employed in drilling and maintenance activities in oilfields and coal mines.

Product Advantage

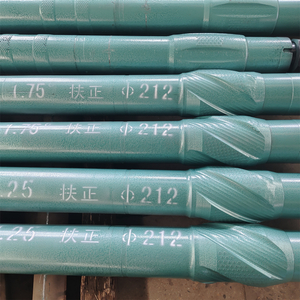

The advantages of utilizing screw drilling tools for directional drilling are as follows:

1. Increased drilling effectiveness: By boosting the number of rotations and torque of the bit, screw drilling tools can enhance the speed of drilling and reduce the time it takes to complete the process.

2. Minimized wear and damage: By directly supplying power from the bottom of the well, screw drilling tools minimize the amount of wear and damage inflicted on the drill pipe.

3. Accurate positioning: Screw drilling tools enable precise positioning, adjustment of slopes, and correction of deviations, resulting in improved economic efficiency for horizontal wells, clustered wells, and well workover operations.

4. Extended tool lifespan: The advanced design of screw drilling tools enhances their durability, leading to a longer lifespan.

5. Adaptability to complex geological conditions: Screw drilling tools are particularly effective in challenging geological conditions, such as extremely hard rocks and steep formations, which ultimately increases the success rate of drilling.

Product Uses

The screw drilling tool for directional drilling is an advanced tool that has various applications:

1. Directional drilling: This tool allows for simultaneous changes in the drilling top angle and azimuth angle during the drilling process. This improves the accuracy of hitting the target and is suitable for different types of strata. It can be used in geological exploration, oil extraction, and other fields.

2. Real-time measurement: When used with directional drillers and single-point directional drillers, it can measure the drilling direction and angle in real time. This makes it convenient to adjust the drilling trajectory promptly, thereby enhancing drilling efficiency and quality.

3. Special drilling operations: In complex geological conditions like horizontal wells and branch wells, the screw drilling tool can adapt better and increase the success rate of drilling.

4. Enhanced drilling efficiency: By increasing the number of bit revolutions and bit torque, the drilling speed can be improved, leading to shorter drilling cycles and reduced costs.

5. Minimized wear and damage: Thanks to its advanced structure, this tool can effectively reduce the wear and damage to the drill pipe.

FAQ

1. What is HDD directional drilling and how does it relate to the PDM downhole motor?

- HDD directional drilling is a method used to drill horizontal or directional wells. The PDM downhole motor is a crucial component in this process, providing the necessary power and torque to drive the drilling bit.

2. How does the PDM downhole motor contribute to the success of horizontal and directional wells?

- The PDM downhole motor plays a vital role in horizontal and directional drilling by providing precise control and maneuverability. It enables operators to navigate challenging formations and achieve accurate wellbore placement.

3. What are the advantages of using a PDM downhole motor in HDD directional drilling?

- The PDM downhole motor offers several advantages, including increased drilling efficiency, reduced drilling time, improved wellbore quality, and enhanced overall project economics. Its reliable performance and durability make it a preferred choice in the industry.

4. Can you explain the concept of a volumetric motor in the context of HDD directional drilling?

- A volumetric motor, such as the PDM downhole motor, operates based on the displacement of fluid within its chambers. This displacement generates rotational motion, allowing the motor to drive the drilling bit. The volumetric design ensures consistent power output and precise control during drilling operations.

5. How does the PDM downhole motor handle different drilling conditions encountered in HDD directional drilling?

- The PDM downhole motor is designed to handle a wide range of drilling conditions, including varying formations, high temperatures, and abrasive environments. Its robust construction and advanced engineering enable it to withstand these challenges while maintaining optimal performance and reliability.

3.4 The order will only be placed once payment has been made for the supply.