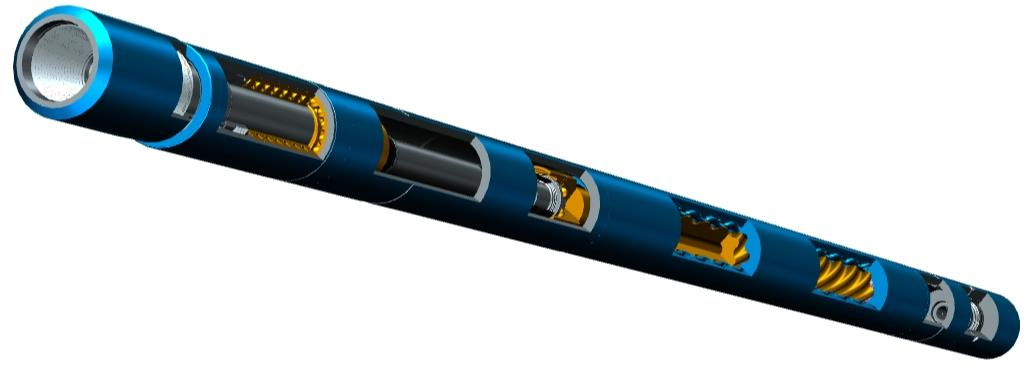

Product Introduction

Saltwater mud motor are tools that use special drilling tool coatings to enable the entire screw drilling tool to work in saturated saltwater mud environments for extended periods of time. Such drilling tools are usually characterized by corrosion and abrasion resistance to meet the demands of working in salt water mud environments.

Product Advantage

The advantages of salt water mud screw drilling tools are mainly reflected in the following aspects:

- Corrosion resistance: the screw drilling tools are coated with special drilling tool coating, which enables them to work for a long time in the saturated salt water mud environment with better corrosion resistance.

- Wear-resistant: under the working condition of salt water mud, the rotor of screw drilling tools has excellent wear-resistant performance, which can prolong the service life of the screw rotor.

Product Uses

1. Application Scenario: Drilling in Highly Corrosive Environments

Description: The Saturated Brine Mud Downhole Motor is specifically designed to protect drilling tools from damage in drilling processes that involve highly corrosive formations. When drilling in such environments, the motor acts as a safeguard, ensuring the integrity and longevity of the drilling equipment. By employing a saturated brine mud, this motor effectively shields the tools from corrosive agents present in the formation, thereby extending the lifespan of the drilling operation.

2. Application Scenario: Offshore Drilling in Saltwater Reservoirs

Description: The Saturated Brine Mud Downhole Motor finds its application in offshore drilling operations that target saltwater reservoirs. In this scenario, the motor plays a crucial role in protecting the drilling tools from the corrosive effects of the saltwater environment. By utilizing a saturated brine mud, the motor forms a protective barrier around the tools, preventing the saltwater from causing any significant damage. This application ensures the smooth and uninterrupted drilling process, enhancing the overall efficiency of offshore drilling operations.

3. Application Scenario: Geothermal Drilling in High-Temperature Environments

Description: Geothermal drilling often involves challenging conditions, including high temperatures and corrosive formations. The Saturated Brine Mud Downhole Motor excels in this application scenario by effectively safeguarding the drilling tools from the detrimental effects of extreme heat and corrosive elements. By utilizing a saturated brine mud, the motor provides a reliable protective layer, preventing the tools from overheating and corrosion. This application ensures the successful completion of geothermal drilling projects in high-temperature environments, minimizing equipment downtime and maximizing productivity.

4. Application Scenario: Drilling in Acidic Formations

Description: When drilling in formations with high acidity levels, the Saturated Brine Mud Downhole Motor becomes indispensable. This motor is specifically designed to protect the drilling tools from the corrosive effects of acidic formations. By employing a saturated brine mud, the motor forms a robust protective layer, effectively shielding the tools from the acidic agents present in the formation. This application scenario ensures the longevity and optimal performance of the drilling equipment, enabling efficient drilling operations in acidic formations.

5. Application Scenario: Drilling in Salt Dome Reservoirs

Description: Salt dome reservoirs pose unique challenges in drilling operations due to the corrosive nature of the salt formations. The Saturated Brine Mud Downhole Motor is tailored to excel in this application scenario by offering exceptional protection to the drilling tools. By utilizing a saturated brine mud, the motor creates a reliable barrier, preventing the corrosive saltwater from deteriorating the tools. This application ensures the durability and reliability of the drilling equipment, facilitating successful drilling operations in salt dome reservoirs.

Product Operate Guide

1. Ground inspection before downhole;

2. Drilling, Although the drill is simple in shape and rigid enough, it is still necessary to control the lowering speed when the drilling tool islowered, otherwise it can be easily damaged by the sand bridge,wellbore shoulder and the casing shoe in the wellbore.

3. Start-up Drilling Tool

4. Normal Drilling,In the process of drilling, to maintain the basic stability of the torque, drilling press should be as smooth as possible

5. Lifting Drills

FAQ

1. What is a Saturated Brine Mud Downhole Motor?

A Saturated Brine Mud Downhole Motor is a type of equipment used in the oil industry. It is designed to operate in high-pressure and high-temperature environments, providing rotational power to the drill bit during drilling operations.

2. What are the advantages of using a Saturated Brine Mud Downhole Motor?

Using a Saturated Brine Mud Downhole Motor offers several advantages. It allows for increased drilling efficiency, improved control over the drilling process, and reduced downtime. Additionally, it can handle abrasive drilling fluids, such as saturated brine mud, without compromising performance.

3. What is the typical lead time for ordering a Saturated Brine Mud Downhole Motor?

The lead time for ordering a Saturated Brine Mud Downhole Motor may vary depending on the specific requirements and customization needed. However, on average, it takes approximately X weeks from placing an order to delivery. Please contact our sales team for more accurate lead time information.

4. What quality standards are followed in the manufacturing of Saturated Brine Mud Downhole Motors?

We adhere to stringent quality standards in the manufacturing of our Saturated Brine Mud Downhole Motors. Our products are designed and manufactured in compliance with industry regulations and undergo rigorous quality control processes to ensure their reliability, durability, and performance.

5. What is the minimum order quantity for Saturated Brine Mud Downhole Motors?

The minimum order quantity for Saturated Brine Mud Downhole Motors may vary depending on the specific model and customization requirements. Please reach out to our sales team to discuss your specific needs and they will provide you with the minimum order quantity information.