Product Introduction

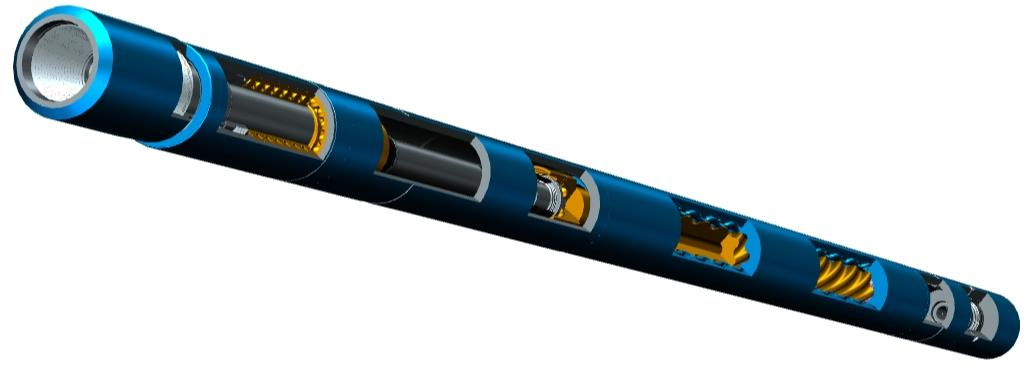

The torque of the trenchless Directional downhole motor is directly proportional to the pressure drop. According to the pressure drop on the pump pressure gauge can also be converted to the torque on the drill bit, which can be more accurately obtained counter torque. This is the outstanding advantage of downhole motor in directional drilling applications.

Product Advantage

The trenchless traversing directional screw drilling tool is a volumetric motor. Its advantages are:

- High torque: The torque generated by the screw drilling tools is only used to drive the drill bit, reducing wear on the drill pipe.

- High inclination rate: Specialized drilling tool combinations for large inclination rates are available, as well as guided drilling tool combinations for continuous control.

- Linear output: The output torque of the screw drilling tools is linearly related to the pressure drop generated by the drilling fluid through the hydraulic motor within a certain range.

- Large Displacement Input: Hollow rotor screw drilling tools can be used with large displacement input to increase upward speed and sand carrying capacity.

- Wide range of application: Applicable to a variety of drill bit options.

Product Uses

1. Municipal Construction:

Application Scenario: The Trenchless Downhole Motor is extensively used in municipal construction projects. It is specifically designed to facilitate the installation of underground utility lines, such as water pipes, gas pipes, and electrical cables, without the need for traditional excavation methods. This motor is capable of maneuvering through various soil types, including clay, sand, and gravel, allowing for efficient and cost-effective installation of utility lines in urban areas.

2. Lake Crossing:

Application Scenario: The Trenchless Downhole Motor finds significant utility in lake crossing projects. When there is a need to install pipelines or cables across lakes or other water bodies, traditional excavation methods can be extremely challenging and costly. In such scenarios, the downhole motor is employed to drill horizontally beneath the lake bed, enabling the installation of utility lines without disturbing the water body. This application scenario ensures minimal disruption to aquatic life and maintains the ecological balance of the lake.

FAQ

Q: About the sample what is the cost of transportation?

A:The freight depends on weight, packing size and your country or province region, etc.You can confirm downhole motor by photo and video to save this money, If you become our old customer.

Q: Do you have stock ?

A:Most of produts are under regular production , we can make delivery immediately if we the specific one in stock.

Q: What is the payment terms?

A: Payment by T/T, L/C, Western Union accepted, other terms can be negotiated.