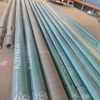

Product Introduction

A mud-powered drilling tool known as a downhole motor is utilized in various drilling techniques such as directional drilling, horizontal drilling, composite drilling, cluster wells, sidetrack wells, and well workover operations. The motor is powered by mud, which is pumped into it through a bypass valve. This creates a pressure difference between the inlet and outlet, causing the motor rotator to rotate. The rotation then transmits torque and speed to the drill bit via a universal shaft and transmission shaft. The performance of the downhole motor depends mainly on its properties. To address a common issue with traditional methods, this product employs advanced coating technology to prevent the rotor from losing its coating. This improvement significantly enhances the motor's strength and lifespan.

Product Advantage

1. Every drilling motor has a submersible device to catch the rotor.

2. Extra buoyant upper subs, release subs, or exclusive subs can be connected to drilling motors.

3. Drilling motors are compatible with both water-based mud (WBM) and oil-based mud (OBM).

4. The casing on the drilling motor can be adjusted within a range of 0 to 3°.

5. Options for stabilizers include screw-on, permanent, or empty variations.

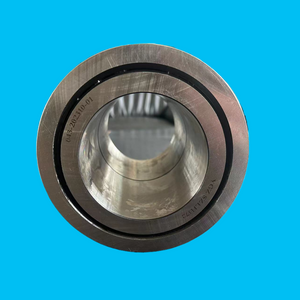

6. The bearing spindle in the drilling motor is specifically engineered to endure high torque power sections.

Product Uses

1. Horizontal Drilling in Oil and Gas Exploration:

In this scenario, the Downhole Drilling Mud Motor is utilized for horizontal drilling in the oil and gas exploration industry. The motor is deployed downhole to provide the necessary rotational force to drive the drill bit horizontally through the rock formations. This application scenario is crucial in accessing reserves that are otherwise difficult to reach using conventional vertical drilling techniques. The Downhole Drilling Mud Motor enables precise control and maneuverability, allowing for efficient extraction of oil and gas resources.

2. Directional Drilling in Geothermal Energy:

The Downhole Drilling Mud Motor finds application in directional drilling for geothermal energy production. Geothermal wells often require drilling at specific angles to access hot water reservoirs deep beneath the earth's surface. The mud motor assists in steering the drill bit accurately along the desired trajectory, ensuring optimal positioning of the wellbore. By enabling precise directional control, the motor helps maximize energy extraction from geothermal sources, contributing to sustainable and renewable energy generation.

3. Underground Mining Operations:

In underground mining operations, the Downhole Drilling Mud Motor plays a vital role in drilling boreholes for various purposes. It is commonly used for drilling blast holes to facilitate controlled rock fragmentation during mining operations. The motor's ability to operate in challenging underground environments, coupled with its high torque output, ensures efficient drilling performance. Additionally, the motor's directional capabilities enable the creation of ventilation shafts, dewatering wells, and exploration holes, enhancing safety and productivity in mining operations.

4. Civil Engineering and Construction:

The Downhole Drilling Mud Motor is extensively employed in civil engineering and construction projects. It aids in the construction of tunnels, pipelines, and underground infrastructure. By providing the necessary rotational force, the motor enables the drilling of precise holes for anchoring structures, installing ground support systems, and creating underground passages. Its ability to operate in various soil and rock formations ensures versatility and efficiency in a wide range of construction applications, promoting the development of robust and reliable infrastructure.

5. Environmental and Geotechnical Investigations:

Environmental and geotechnical investigations often require drilling boreholes to assess soil and rock properties, groundwater levels, and contamination levels. The Downhole Drilling Mud Motor facilitates these investigations by providing the necessary power and control to drill boreholes of varying depths and angles. The motor's ability to navigate through different soil and rock formations ensures accurate sampling and data collection, aiding in environmental assessments, site characterization, and geotechnical studies.

FAQ

What is the estimated delivery time for your items?

The delivery time may vary depending on the model and quantity of your order. Typically, if the machines are available, it will take approximately 30 days.

What payment methods do you accept?

We usually accept payments through T/T or L/C.

How are the items transported?

For small orders, we recommend using courier express services like DHL/UPS/FEDEX or air shipping. For larger orders, air or sea shipping is suggested.

How is the quality of the items ensured?

We have a dedicated team of experienced quality control professionals. Each order undergoes rigorous inspection and testing before it is shipped out.

What is the packaging like?

The items are packed in either white boxes or color boxes upon request. The outer packaging consists of cartons or pallets.

What are the shipment terms?

The items will be shipped approximately 30 days after receiving the initial payment, or as mutually agreed upon.