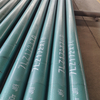

Product Introduction

The primary component of the bottom hole assembly (BHA) that facilitates efficient and precise drilling operations is the drill motor. These motors, which are extremely effective, generate rotational force to drive the drill bit. With advanced technology and exceptional design, drill motors offer enhanced torque, speed, and reliability.

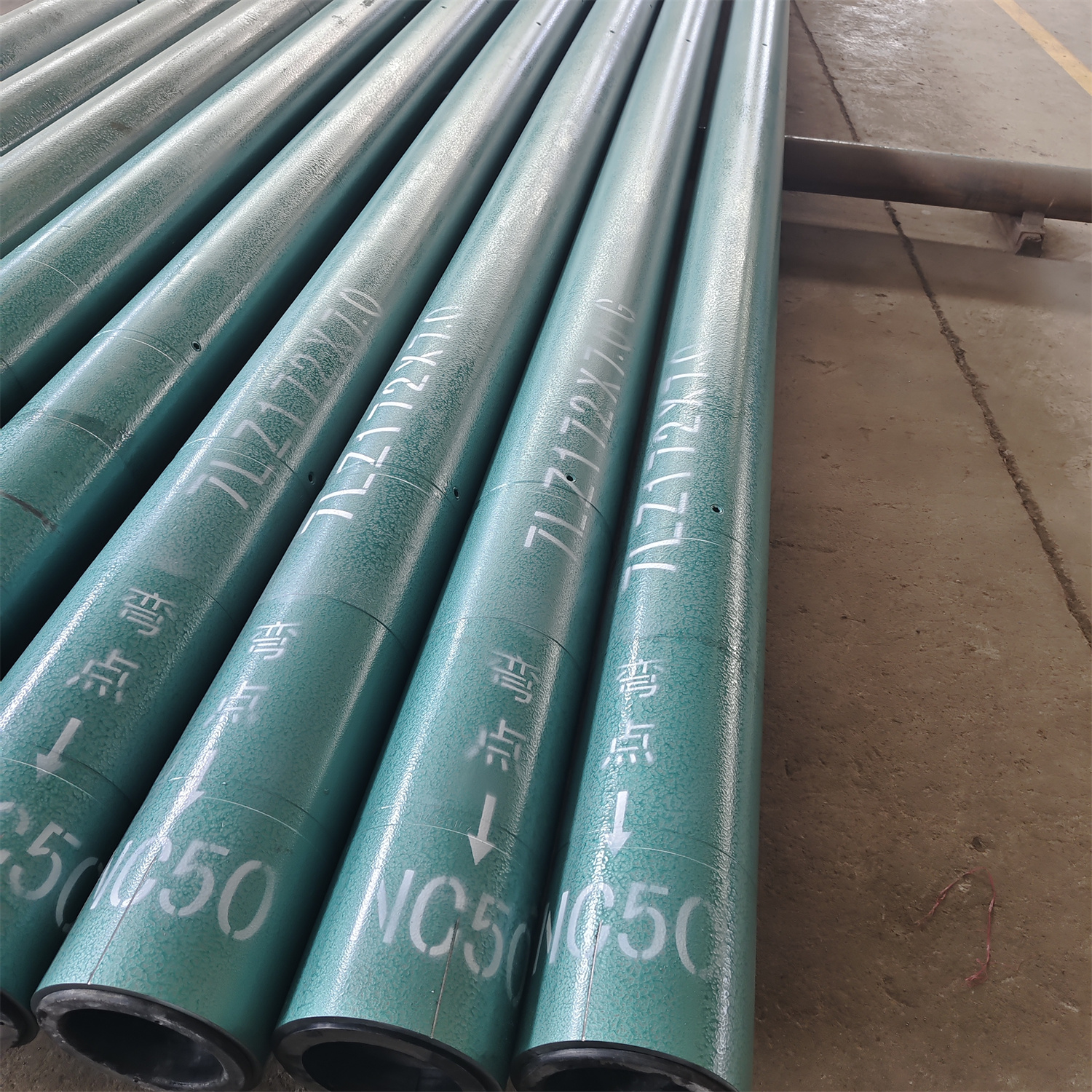

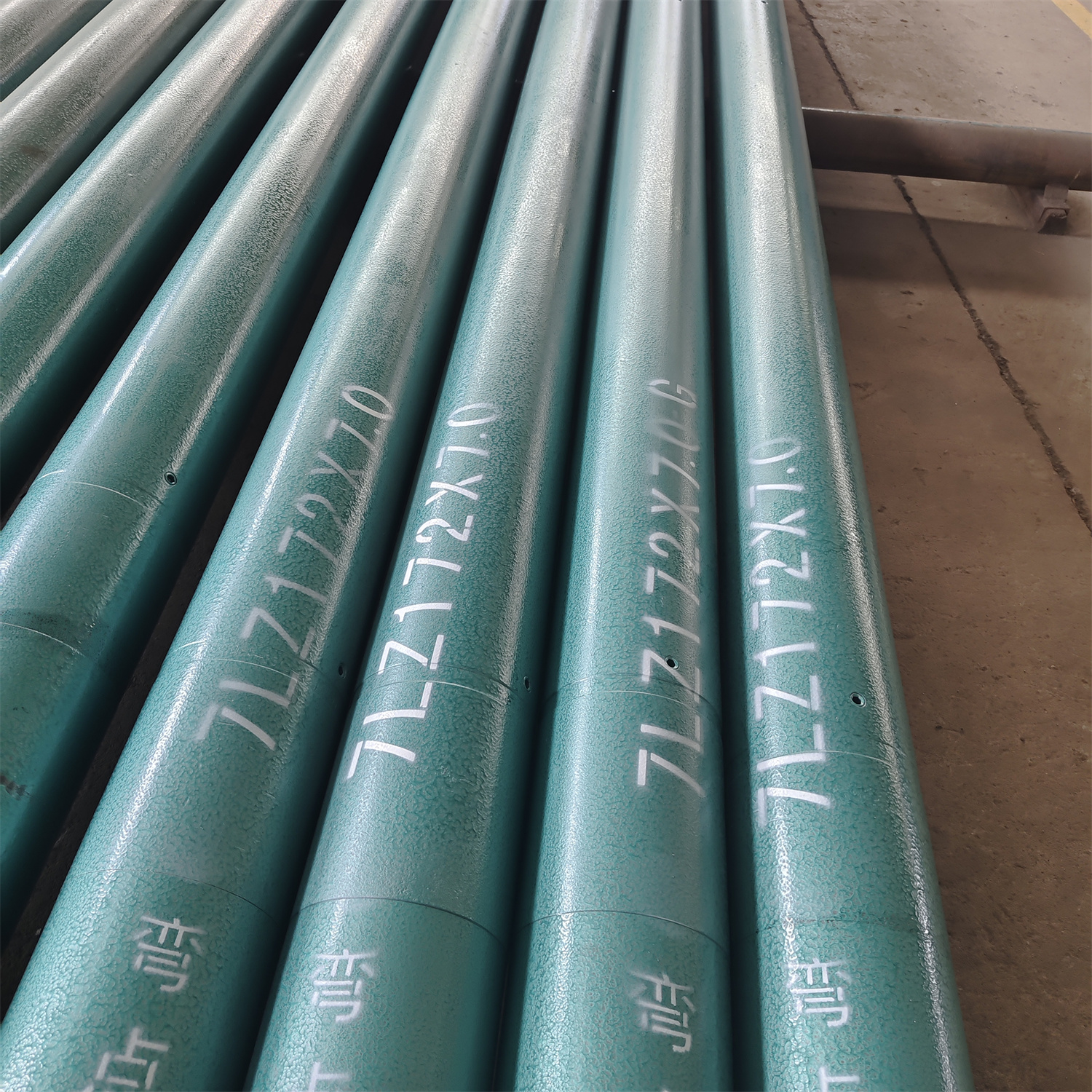

The drill motor is a specific type of motor called a positive displacement motor (PDM). This motor receives high-pressure drilling fluid, which converts the fluid's energy into mechanical power. The rotor then propels the shaft, causing the bit to rotate. We possess the capability to manufacture drill motors for various hole sizes, ranging from 1 7/8" to 26". Furthermore, we can customize and produce drill motors to meet the specific requirements of our clients.

Product Advantage

1. Each drilling motor comes with a sub that captures the rotor.

2. Drilling motors can be equipped with a floating upper sub, a discharge sub, or a special sub for capturing.

3. Drilling motors work well with both water-based mud (WBM) and oil-based mud (OBM).

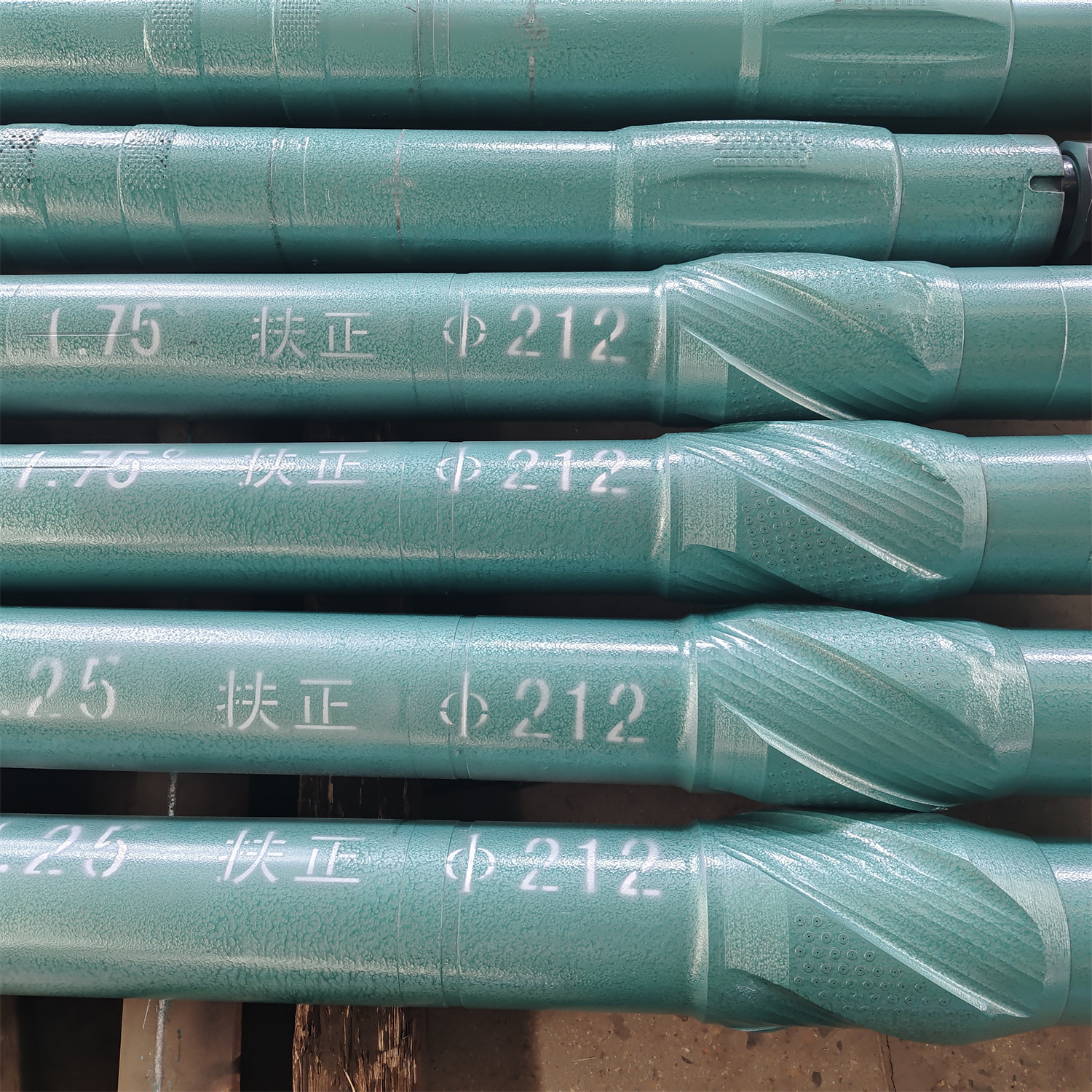

4. Equipped with adjustable housings that can be set from 0 to 3°.

5. You can choose between screw-on stabilizers, fixed stabilizers, or blank stabilizers.

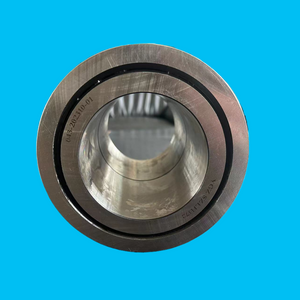

6. The bearing mandrel in the drilling motor is specially designed to handle high torque power sections.

Product Uses

1. Mining Operations:

In mining operations, the Downhole Motors for Mines with Superb Rock-Carrying Capacity play a crucial role in drilling and excavation processes. These motors are specifically designed to withstand the demanding conditions encountered in mines. With their exceptional rock-carrying capacity, they enable efficient drilling and excavation by effectively transporting rocks and debris to the surface. The motors' high displacement mud circulation capability ensures smooth and uninterrupted drilling operations, even in high-volume mud circulation scenarios. Additionally, their outstanding wear resistance ensures prolonged durability, reducing downtime and maintenance costs in mining operations.

2. Oil and Gas Exploration:

The Downhole Motors for Mines with Superb Rock-Carrying Capacity find extensive application in oil and gas exploration activities. These motors are utilized in directional drilling, where precise control and maneuverability are essential. With their powerful rock-carrying capacity, they effectively transport rock cuttings and drilling fluids to the surface, ensuring uninterrupted drilling operations. The motors' ability to handle high mud circulation rates is particularly advantageous in oil and gas exploration, where large volumes of drilling fluids need to be circulated. Furthermore, their exceptional wear resistance enables them to withstand the abrasive conditions encountered in drilling deep into the earth's crust.

3. Geothermal Drilling:

Geothermal drilling involves extracting heat from the earth's interior for various applications. The Downhole Motors for Mines with Superb Rock-Carrying Capacity play a vital role in geothermal drilling operations. These motors excel in transporting rocks and cuttings to the surface, ensuring efficient drilling progress. Their ability to handle high mud circulation rates is crucial in geothermal drilling, where effective heat transfer requires continuous circulation of drilling fluids. Moreover, the motors' exceptional wear resistance ensures longevity, reducing the need for frequent replacements and minimizing downtime in geothermal drilling projects.

4. Construction and Tunneling:

In construction and tunneling projects, the Downhole Motors for Mines with Superb Rock-Carrying Capacity offer significant advantages. These motors are employed in drilling and excavation tasks, where their exceptional rock-carrying capacity proves invaluable. By efficiently transporting rocks and debris to the surface, they facilitate smooth and productive drilling operations. The motors' high displacement mud circulation capability enables effective mud circulation in construction and tunneling projects, ensuring the stability and integrity of the drilled structures. Additionally, their outstanding wear resistance ensures prolonged durability, minimizing maintenance requirements and enhancing overall project efficiency.

5. Water Well Drilling:

Water well drilling requires reliable and efficient drilling equipment to access underground water sources. The Downhole Motors for Mines with Superb Rock-Carrying Capacity find application in water well drilling due to their exceptional performance characteristics. These motors excel in transporting rocks and cuttings to the surface, enabling efficient drilling progress. Their ability to handle high mud circulation rates is particularly advantageous in water well drilling, where continuous circulation of drilling fluids is necessary for effective drilling and well completion. Furthermore, the motors' outstanding wear resistance ensures longevity, reducing downtime and maintenance costs in water well drilling operations.

FAQ

What is your procedure for handling my inquiry?

Initially, we will communicate through email or TM to discuss the details of your order and production. Once everything is finalized, we will send you a PI for your confirmation. Before we can proceed with production, we will require you to make a full payment or deposit. Once we receive the deposit, we will begin processing your order. If the items are not in stock, it usually takes us 7-15 days to complete the production. Before the production is finished, we will reach out to you to discuss shipment details and the remaining payment. Once the payment is settled, we will prepare the shipment for you.

How can I make the payment for the order?

Once you confirm our PI, we will ask you to make the payment. We accept various payment methods such as T/T, L/C, D/P, and Western Union. If none of these methods are convenient for you, we can discuss alternative payment options.

What is your policy on after-sales service?

If you require after-sales service, please contact our sales manager and clearly explain the issue. Our dedicated after-sales support team will assist you until the problem is resolved. There are two common types of after-sales requests:

1) Related to the current batch of goods: If you have any questions regarding the operation, maintenance, or upkeep of the product, most of the information can be found in the product manual.

orma Invoice (PI) for your confirmation. Before we begin production, we will require you to make a full payment or deposit. If the items are not in stock, it typically takes us 7-15 days to complete the production. Prior to finishing production, we will contact you to arrange the shipment and discuss the remaining payment. Once the payment has been settled, we will prepare the shipment for you.