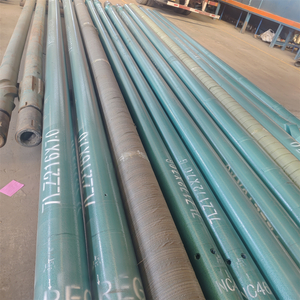

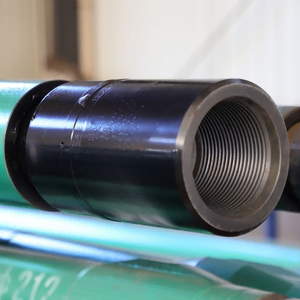

Product Introduction

The steel PDC drill bit is a popular tool for drilling in the oil and gas industry, as it blends the durability of steel with the cutting power of polycrystalline diamond composite (PDC) elements.

Made from tough alloy steel, the steel body of PDC drill bits offers strength and stability during drilling operations. The PDC composite layer, located at the cutting edge of the bit, is comprised of a layer of polycrystalline diamond and a sturdy alloy base. These composite sheets are incredibly hard and resistant to wear, making them ideal for breaking through rock formations.

Product Advantage

1. Effective drilling: The durability of PDC composite sheets enables the drill bit to cut through rocks more quickly, enhancing drilling speed and effectiveness.

2. Extended durability: The toughness of PDC composite sheets prolongs the lifespan of drill bits, decreasing the need for replacements and lowering drilling expenses.

3. Versatile performance: Steel PDC drill bits are appropriate for a range of formations, such as soft, medium hard, and hard formations.

4. Reliable consistency: The steel construction offers stability to the drill bit, ensuring the verticality and uniformity of the drilling hole diameter.

Product Uses

1. Oil Field Drilling:

The Hard Rock Formation Steel Matrix Body Oil Well PDC Bit is specifically designed for drilling in oil fields. Its durable steel matrix body and high-quality PDC (Polycrystalline Diamond Compact) cutters ensure efficient and reliable performance in tough rock formations commonly found in oil fields. This PDC bit is ideal for both vertical and horizontal drilling applications, providing superior penetration rates and extended bit life in challenging drilling conditions.

2. Coal Mine Drilling:

For coal mine drilling operations, the Hard Rock Formation Steel Matrix Body Oil Well PDC Bit offers exceptional durability and performance. Its robust construction and advanced PDC technology make it well-suited for drilling through hard coal seams and abrasive rock formations. This PDC bit delivers consistent drilling performance, increased footage drilled, and reduced downtime, making it a reliable choice for coal mining applications.

3. Geological Exploration:

In geological exploration projects, precision drilling is essential to obtain accurate data and samples. The Hard Rock Formation Steel Matrix Body Oil Well PDC Bit excels in this application scenario, providing high drilling efficiency and excellent borehole quality. With its optimized design and superior cutting structure, this PDC bit ensures smooth drilling operations in various geological formations, allowing geologists to gather valuable information with precision and accuracy.

4. Non-Excavation Engineering:

The Hard Rock Formation Steel Matrix Body Oil Well PDC Bit is also well-suited for non-excavation engineering projects, such as pipeline installation, underground utilities, and environmental monitoring. Its versatile design and reliable performance make it a valuable tool for drilling in urban areas or sensitive environments where traditional excavation methods are impractical. This PDC bit offers efficient drilling capabilities, minimal environmental impact, and cost-effective solutions for various non-excavation engineering applications.

FAQ

Q: Are you a manufacturer?

A: Yes, we are factory.

Q:Would you tell me the main items you export?

A: Our company mainly deals with Downhole motor , PDC bits, PC pumps, downhole tools and other petroleum equipment.

Q: May I have a look at your catalogue?

A: Sure, I'll send you our catalog in your mailbox!

Q: We really need more information about your technology.

A: I will send you our detailed company profile and information.