Product Introduction

Introducing our High Torque Downhole Motor, a sophisticated drilling tool designed to excel in complex well conditions. With its powerful torque and ample power, this motor is engineered to deliver exceptional performance. The motor is crafted using high-quality imported rubber, ensuring durability and reliability. Trust our High Torque Downhole Motor to tackle even the most challenging drilling tasks with ease.

Product Advantage

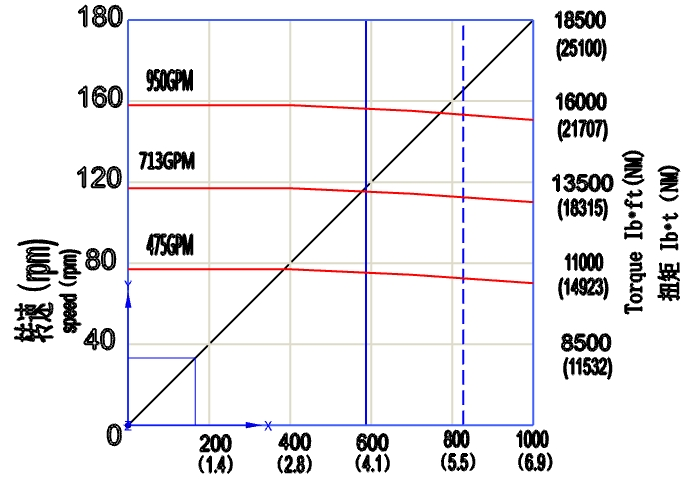

- High torque: the maximum output torque of high torque screw drilling tools is large, which can meet the working demand under high load and difficult working environment.

- High efficiency: The high output power of high torque screw drilling tools can effectively improve the working efficiency and reduce the working time.

- Stability: The structural design of high torque screw drilling tools is more stable, which can effectively reduce the mechanical failure rate in the process of operation and improve the stability of operation.

- Safety: High torque screw drilling tools are equipped with corresponding safety protection devices, which can effectively protect the personal safety of operators.

Product Uses

1. Application Scenario: Drilling in Deep Wells with Complex Well Conditions

Description: The High Torque Downhole Motor is specifically designed to address the challenges faced during drilling operations in deep wells with complex well conditions. This application scenario typically involves drilling in oil and gas exploration or geothermal projects where the depth of the well exceeds conventional drilling limits, and the wellbore encounters various geological formations, high temperatures, and high pressures.

The High Torque Downhole Motor is an indispensable tool in such scenarios as it provides the necessary power and torque to overcome the increased drilling difficulty. Its robust construction and advanced engineering enable it to withstand the extreme downhole conditions and deliver exceptional performance.

2. Application Scenario: Directional Drilling in Challenging Environments

Description: The High Torque Downhole Motor finds extensive use in directional drilling applications where precise wellbore trajectory control is required in challenging environments. This application scenario is commonly encountered in oil and gas exploration, mining, and underground construction projects.

In this scenario, the High Torque Downhole Motor allows operators to navigate the wellbore along specific paths, such as horizontal or deviated drilling, to reach target zones accurately. Its high torque output ensures efficient drilling progress even in hard rock formations or formations with varying hardness. The motor's superior control and stability enable precise steering, reducing the risk of wellbore deviation and maximizing drilling success.

3. Application Scenario: Extended Reach Drilling in Reservoir Optimization

Description: Reservoir optimization often necessitates drilling wells with extended reach to access remote or previously untapped hydrocarbon reserves. The High Torque Downhole Motor plays a vital role in this application scenario, enabling efficient drilling in long horizontal or highly deviated wellbores.

In this scenario, the High Torque Downhole Motor's exceptional torque capabilities ensure reliable drilling performance over extended distances. It enables operators to reach reservoirs that were previously inaccessible, maximizing the production potential of the well. The motor's advanced design minimizes vibration and enhances stability, reducing the risk of wellbore instability and improving drilling efficiency in complex reservoir formations.

4. Application Scenario: Underbalanced Drilling for Wellbore Stability

Description: Underbalanced drilling techniques are employed to maintain wellbore stability and prevent formation damage during drilling operations. The High Torque Downhole Motor is an essential component in this application scenario, enabling the successful execution of underbalanced drilling techniques.

FAQ

1. Question: What is a High Torque Downhole Motor?

Answer: A High Torque Downhole Motor is a tool used in the oil and gas industry for drilling and completion operations. It provides high torque power to rotate the drill bit and helps in efficient drilling processes.

2. Question: How long is the delivery time for the High Torque Downhole Motor?

Answer: The delivery time for our High Torque Downhole Motor may vary depending on the specific model and quantity ordered. Please contact our sales team for accurate delivery time estimates.

3. Question: What are the transportation options for shipping the High Torque Downhole Motor?

Answer: We offer various transportation options for shipping the High Torque Downhole Motor, including air freight, sea freight, and land transportation. Our team will work with you to determine the most suitable and cost-effective option based on your location and urgency.

4. Question: What quality standards does the High Torque Downhole Motor meet?

Answer: Our High Torque Downhole Motor is manufactured to meet the highest quality standards in the industry. It undergoes rigorous testing and inspection processes to ensure optimal performance, reliability, and durability.

5. Question: What is the warranty period for the High Torque Downhole Motor?

Answer: We provide a standard warranty period for our High Torque Downhole Motor, which typically covers any manufacturing defects or malfunctions. The specific warranty period may vary depending on the product model, so please refer to the product documentation or contact our customer support for detailed information.