Product Introduction

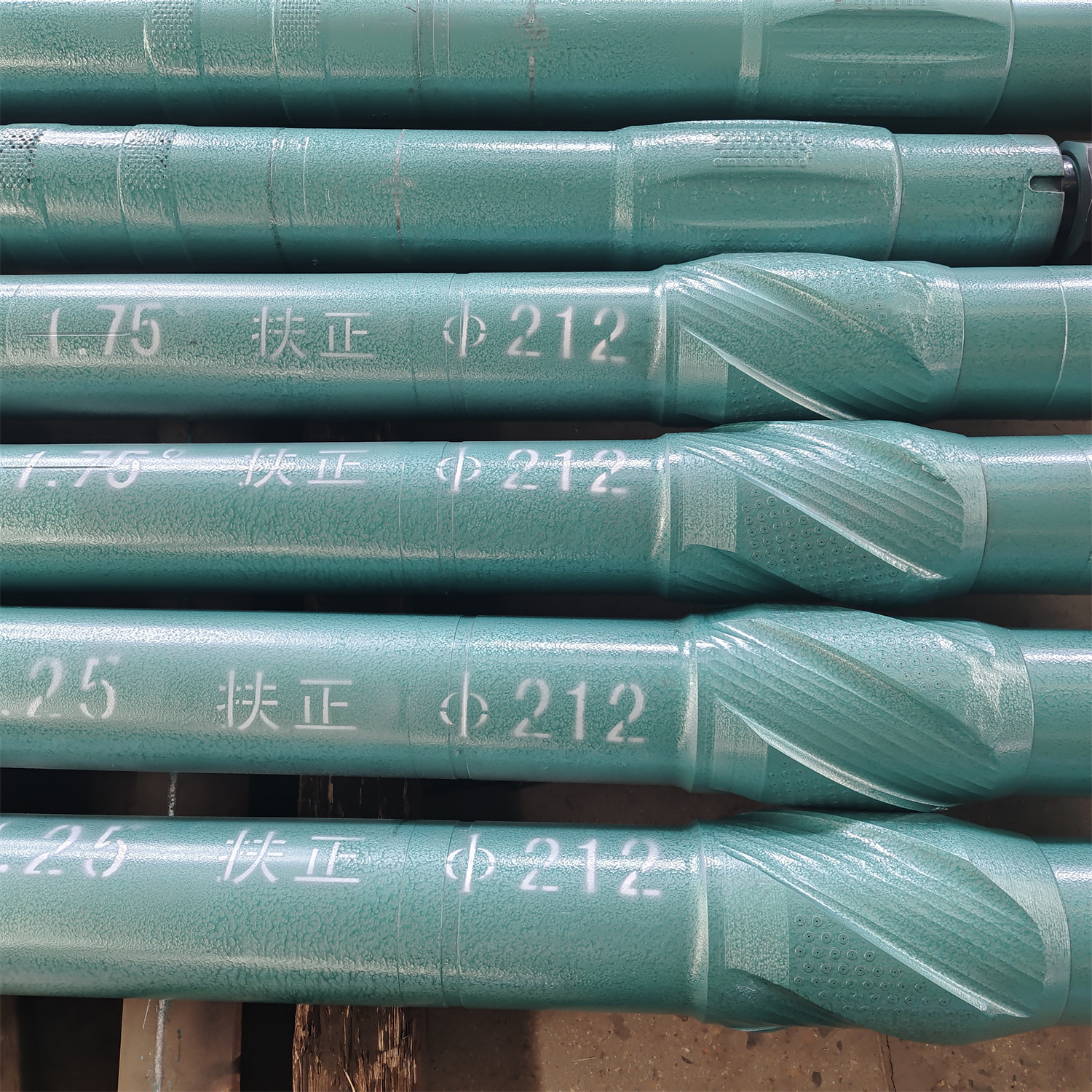

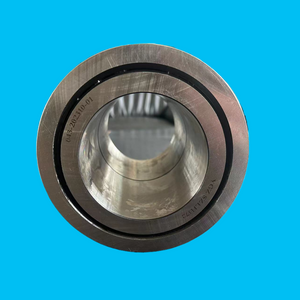

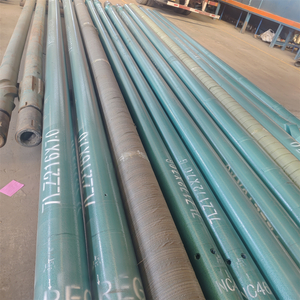

A downhole motor is a tool used for drilling that harnesses the power of drilling fluid to convert liquid pressure into mechanical energy. As the mud pump sends mud into the motor, the pressure changes at the motor's inlet and outlet, causing the rotor to rotate around the stator's axis. This rotation then transfers torque and speed to the drill bit through a universal shaft and transmission shaft, allowing for drilling operations. Downhole motors are widely utilized in oilfield and coal mine drilling and workover activities.

Product Advantage

The advantages of directional drilling screw drilling tools mainly include the following aspects:

Improve drilling efficiency: it can increase the number of bit revolutions and bit torque, thus increasing the feed rate and shortening the drilling cycle.

Reduced wear and damage: Power is supplied directly from the bottom of the well, which reduces wear and damage to the drill pipe.

Accurate Orientation: It can accurately orient, slope and correct deviation, which can significantly improve drilling economic efficiency in horizontal wells, clumped wells and well workover operations.

Improve the life of drilling tools: due to the advanced structure, it improves the life of drilling tools.

Adaptation to complex geological conditions: under some complex geological conditions, such as high rock hardness and large inclination angle of formation, screw drilling tools can be better adapted to improve the success rate of drilling.

Product Uses

Directional drilling screw drilling tool is an advanced drilling tool with the following applications:

Directional drilling: able to change the drilling top angle and azimuth angle at the same time during the drilling process to improve the precision of hitting the target, which is suitable for all kinds of strata and can be applied in geological exploration, oil extraction and other fields.

Measurement with drilling: together with the directional driller and single-point directional driller, it can measure the drilling direction and angle in real time, which is convenient for timely adjusting the drilling trajectory and improving the drilling efficiency and quality.

Special drilling operations: In some special drilling operations, such as horizontal wells and branch wells, screw drilling tools can better adapt to the complex geological conditions and improve the success rate of drilling.

Improve drilling efficiency: By increasing the number of bit revolutions and bit torque, the drilling speed can be increased, the drilling cycle can be shortened, and the cost can be reduced.

Reduce wear and damage: Due to the advanced structure, it can reduce the wear and damage of drill pipe and prolong the service life.

Adapt to complex geological conditions: screw drilling tools can still work normally under complex geological conditions such as high rock hardness and large inclination of strata.

FAQ

1. Are you a manufacturer or trading company?

Our company is a business that combines manufacturing and trading. This means that we not only produce downhole motors and related products and accessories, but also sell them domestically and internationally.

2. How do you ensure the quality of your products?

We manufacture our downhole motors according to API standards. We have always maintained strict quality control throughout the entire production process, from the raw materials to the finished products. We never allow any substandard parts to proceed to the next stage, ensuring that each downhole motor passes inspection before being delivered.

3. How can I place an order?

3.1 To place an order, our customers need to provide us with the product name, quantity, detailed specifications, packaging requirements, and any other relevant conditions. It would be helpful if they could also provide us with pictures or videos of similar products, so that we can have a clear understanding of their needs.

3.2 Based on the customer's requirements, we will provide an offer and detailed specifications for their confirmation.

3.3 Once the customer confirms the offer, we will prepare a proforma invoice (P/I) for both parties to sign and stamp.

3.4 The order will only be placed once payment has been made for the supply.