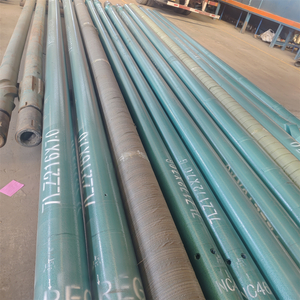

Product Introduction

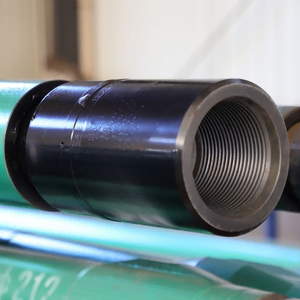

High flow rate downhole motor is a kind of volumetric downhole power drilling tool that uses drilling fluid as power and converts liquid pressure energy into mechanical energy.

Product Advantage

- Large displacement: large displacement screw drilling tools have a larger displacement, which can meet the needs of working in complex formations and deep wells.

- Increased torque and power: Increased feed rates help improve drilling efficiency.

- Reduced Wear and Tear: Reduces wear and damage to drill pipe and casing, extending the service life of the equipment.

- Accurate control of direction: it can accurately perform orientation, inclination and deviation correction, which improves the control accuracy of the borehole trajectory.

Product Uses

1. Application Scenario: Horizontal Drilling in Complex Reservoirs

Description: In the field of oil and gas exploration, the high flow rate downhole motor finds its application in horizontal drilling operations carried out in complex reservoirs. When faced with challenging drilling conditions such as intricate geological formations, highly deviated well trajectories, or narrow pore spaces, this advanced motor proves to be highly effective. Its primary function is to provide a large displacement capacity, enabling efficient drilling in such demanding scenarios.

2. Application Scenario: Extended Reach Drilling in Deepwater Wells

Description: The high flow rate downhole motor is extensively used in extended reach drilling operations conducted in deepwater wells. These drilling projects often involve drilling at great depths and long horizontal stretches, presenting significant technical difficulties. With its ability to handle high flow rates, this motor excels in such scenarios, ensuring smooth and efficient drilling operations. Its robust design and advanced technology enable the motor to overcome the challenges posed by extreme water depths and complex well architectures.

3. Application Scenario: Directional Drilling in Hard Rock Formations

Description: The high flow rate downhole motor is specifically designed to tackle directional drilling challenges encountered in hard rock formations. In scenarios where conventional drilling techniques struggle to penetrate tough rock formations, this motor proves to be a game-changer. Its exceptional torque and power capabilities allow it to efficiently navigate through hard formations, enabling precise wellbore placement. This application is particularly crucial in the oil and gas industry, where accurate positioning of wells is essential for optimal reservoir exploitation.

4. Application Scenario: Geothermal Well Drilling in High-Temperature Environments

Description: Geothermal energy extraction often involves drilling wells in high-temperature environments, where conventional drilling methods face limitations. The high flow rate downhole motor is well-suited for such demanding geothermal drilling operations. Its superior heat resistance, coupled with its ability to handle large flow rates, enables efficient drilling in extreme temperatures. By withstanding the harsh conditions and maintaining consistent performance, this motor ensures the successful development of geothermal resources, contributing to the growth of renewable energy.

5. Application Scenario: Underbalanced Drilling in Unstable Formations

Description: Underbalanced drilling techniques, aimed at preventing formation damage and improving well productivity, require specialized equipment to maintain the delicate balance between wellbore pressure and formation pressure. The high flow rate downhole motor plays a crucial role in such underbalanced drilling scenarios, particularly in unstable formations. Its high displacement capacity and precise control allow for effective drilling while maintaining the desired pressure differentials. This application helps optimize drilling operations, minimize formation damage, and enhance well productivity.

FAQ

1. What is a high flow rate downhole motor?

A high flow rate downhole motor is a tool used in the oil and gas industry to provide rotational power for drilling operations. It is designed to deliver a high volume of drilling fluid or mud to effectively cool and clean the drill bit, allowing for efficient drilling.

2. How does a high flow rate downhole motor work?

A high flow rate downhole motor operates by utilizing the flow of drilling fluid or mud to generate rotational power. The fluid enters the motor, causing a rotor to rotate, which in turn drives the drill bit. The high flow rate capability of this motor ensures effective cooling and cleaning of the drill bit, enhancing drilling efficiency.

3. What is the warranty period for the high flow rate downhole motor?

The warranty period for our high flow rate downhole motor is [insert warranty period]. We stand behind the quality and performance of our product, and in the unlikely event of any manufacturing defects or malfunctions within the warranty period, we will provide necessary repairs or replacements.

4. Do you have the high flow rate downhole motor in stock?

Yes, we maintain a sufficient inventory of our high flow rate downhole motor to meet the demands of our customers. However, availability may vary depending on the specific model and quantity required. We recommend contacting our sales team to confirm the current stock status and discuss your specific requirements.

5. Is your high flow rate downhole motor manufactured in-house or outsourced?

Our high flow rate downhole motor is proudly manufactured in our own factory. We have a dedicated team of skilled professionals and state-of-the-art facilities to ensure the highest quality standards are met throughout the manufacturing process. This allows us to have complete control over the production and maintain strict quality control measures.