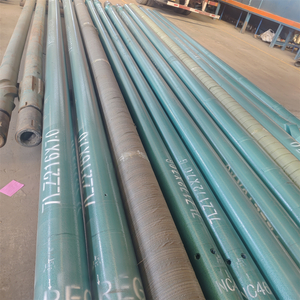

Product Introduction

The thrust bearing is the direct force bearing component that bears drilling pressure, and this super bearing can meet the requirements of high drilling pressure and long service life.Multi-row radial thrust ball bearing is a kind of rolling bearing that can bear axial and radial loads at the same time, and its main feature is that it has high precision and rigidity at high speed. Multi-row radial thrust ball bearings are usually used in applications that need to withstand both axial and radial loads, and are an important part of downhole motors.

Product Advantage

1. Shengde TC bearings possess remarkable qualities like excellent resistance to corrosion, ability to withstand impacts, and high capacity to carry heavy loads.

2. These bearings have a prolonged lifespan and exhibit impressive anti-friction properties.

3. The appearance and technical specifications of Shengde TC bearings surpass those of comparable foreign products.

Product Uses

Multi-row centripetal thrust ball bearings are a kind of special bearings used in downhole power drilling tool transmission section, usually adopting multi-row tandem structure, made of special materials, with large bearing capacity, impact resistance, simple structure, easy disassembling and assembling, able to withstand bi-directional axial loads and so on, suitable for the occasions with low rotational speeds, large loads and severe vibrations.

FAQ

1. What is a thrust bearing and bearing assembly?

A thrust bearing and bearing assembly is a component used in downhole motors to support axial loads and facilitate rotational movement. It helps reduce friction and wear, ensuring smooth operation and extended motor life.

2. How can I ensure the quality of thrust bearings and bearing assemblies?

Our thrust bearings and bearing assemblies undergo rigorous quality control measures to ensure their reliability and performance. We adhere to industry standards and conduct thorough testing at various stages of production. Additionally, we can provide certificates of quality upon request.

3. Do you hold any patents for your thrust bearings and bearing assemblies?

Yes, we have obtained patents for our innovative designs and technologies incorporated into our thrust bearings and bearing assemblies. These patents demonstrate our commitment to continuous improvement and provide added value to our customers.

4. What is the current inventory status of your thrust bearings and bearing assemblies?

We maintain a well-stocked inventory of thrust bearings and bearing assemblies to meet the demands of our customers. However, availability may vary depending on specific models and quantities. Please contact our sales team for the most up-to-date information on stock levels.

5. What is the typical lead time for delivery of thrust bearings and bearing assemblies?

Our standard lead time for delivering thrust bearings and bearing assemblies is [insert lead time]. However, this may vary depending on factors such as order volume and customization requirements. We strive to expedite the delivery process and provide accurate delivery estimates to our customers.