Product Introduction

Cutting-Edge Tool for Directional Well Drilling

The cutting-edge positive displacement motor (PDM) is a crucial tool for navigating challenging drilling conditions. This high-torque and high-performance device is designed to handle tough rock formations and complex well paths with ease. By providing exceptional torque output, the PDM allows for efficient and continuous drilling, reducing both time and costs. Equipped with advanced technology and quality components, this tool offers precise control over drilling direction and penetration rate. By following the planned trajectory accurately, it minimizes errors and improves the overall quality of well construction, leading to enhanced reservoir productivity.

Our Advantage

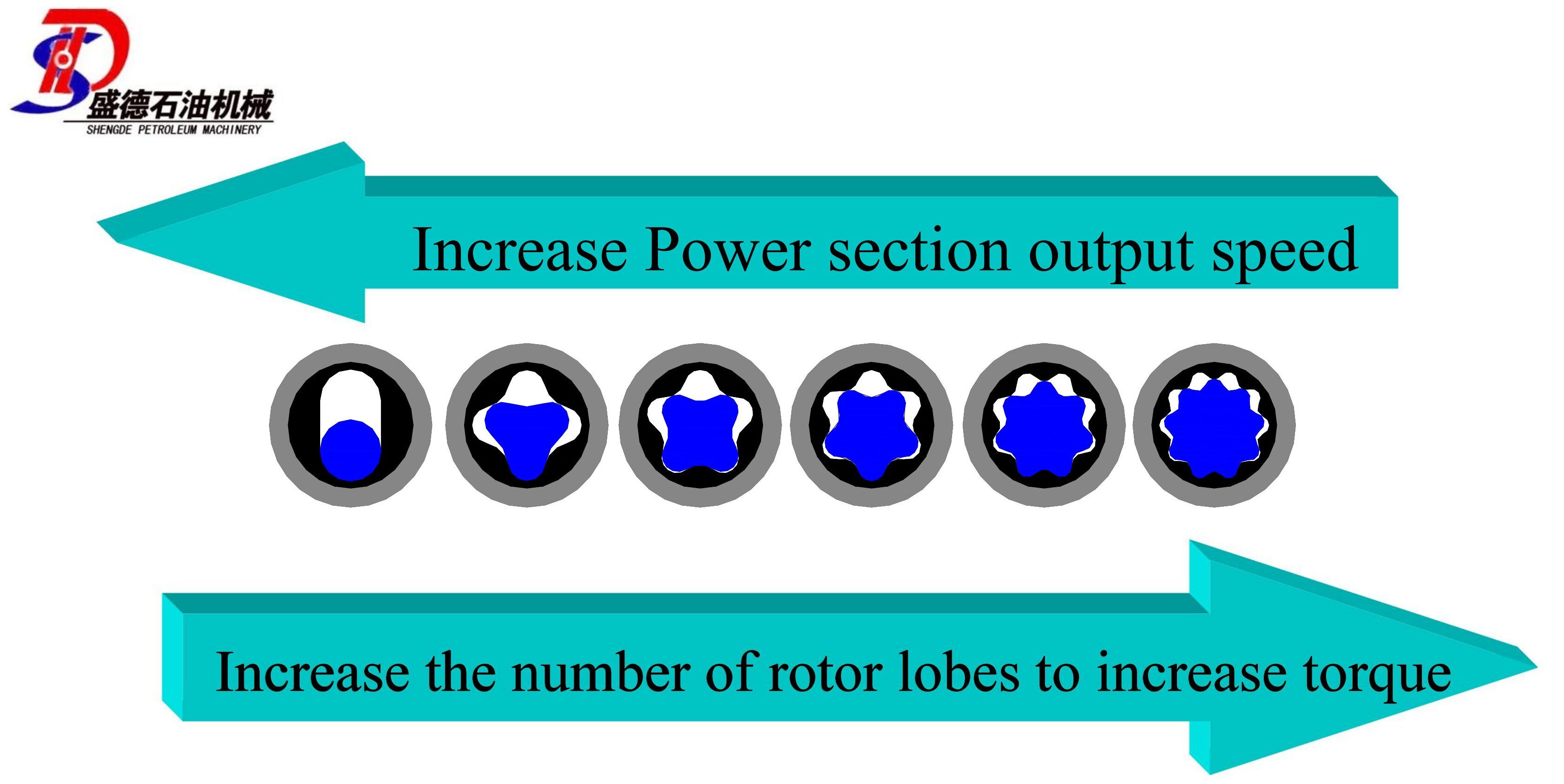

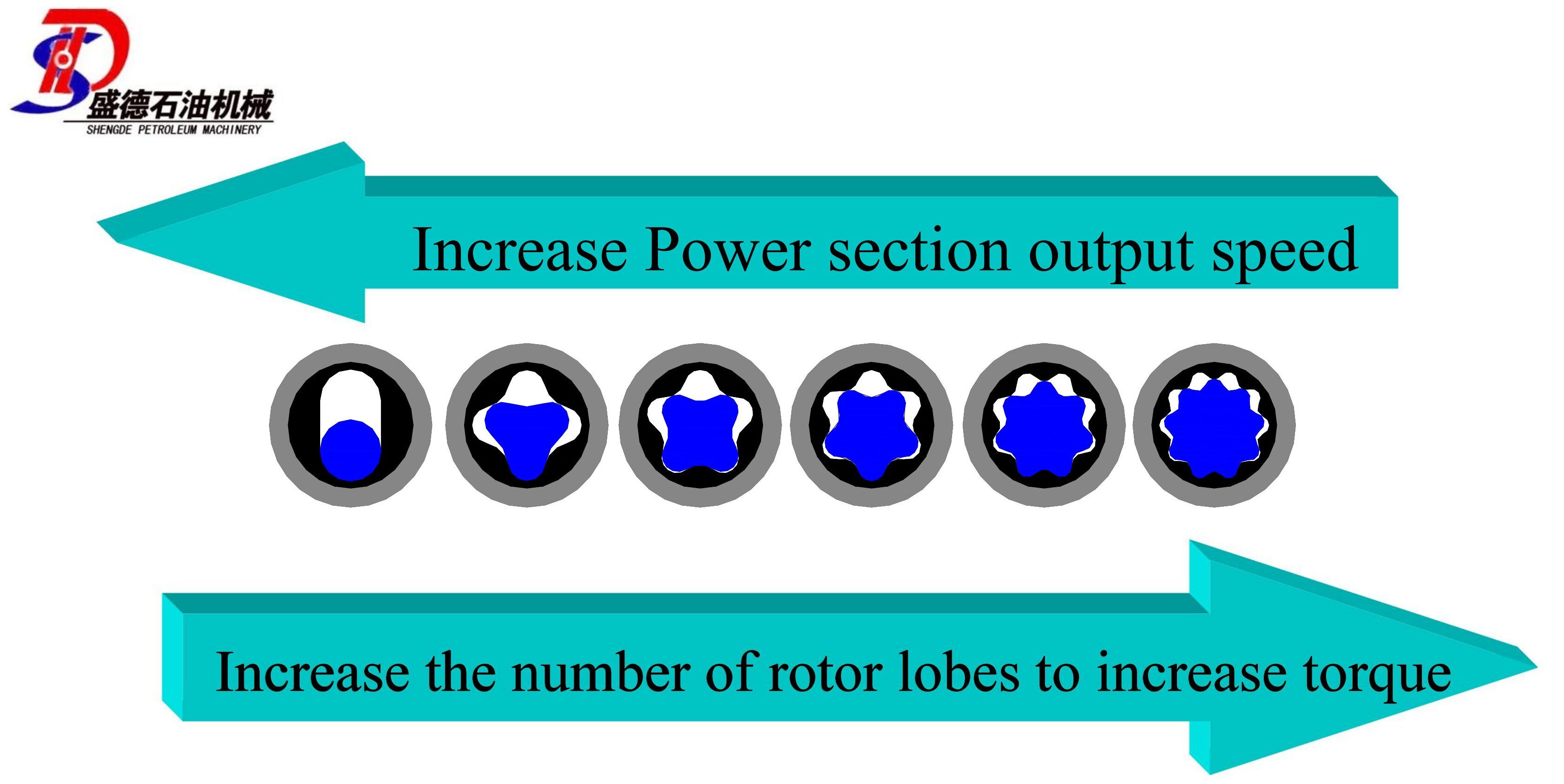

Robust Torque Generation Capability

Positive Displacement Motors (PDMs) are designed to produce remarkable torque. Their unique helical rotor - stator configuration efficiently converts hydraulic power into high - torque rotational motion. This high torque allows PDMs to drill through extremely hard and heterogeneous formations, including high - strength igneous rocks and abrasive conglomerates. In contrast to traditional drilling mechanisms, PDMs can maintain a consistent and powerful drilling force, which not only accelerates the drilling speed but also ensures smooth and continuous penetration, thus significantly enhancing drilling efficiency in difficult geological settings.

Unparalleled Drilling Precision

High - precision PDMs are equipped with state - of - the - art alignment and guidance systems. Advanced manufacturing processes ensure that the internal components are fabricated with tight tolerances, minimizing any potential misalignment during operation. This results in highly accurate drilling trajectories. In oil and gas drilling, where hitting specific reservoir targets with millimeter - level precision is often required, PDMs can precisely control the wellbore direction, reducing the margin of error to a minimum. This precision not only maximizes reservoir contact but also helps in preventing wellbore instability issues associated with off - target drilling, ultimately leading to cost savings in terms of both drilling operations and reservoir exploitation.

Exceptional Durability for Long - Term Use

Constructed from high - quality, wear - resistant materials, PDMs are engineered to endure the harsh environment of drilling operations. The stator is typically made of specialized elastomers that can withstand high pressures, abrasive fluids, and elevated temperatures, while the rotor is crafted from hardened alloys to resist mechanical wear. These materials, combined with a robust mechanical design, enable PDMs to operate continuously for extended periods without significant degradation in performance. This durability reduces the frequency of equipment replacements and maintenance, minimizing unplanned downtime and overall operational costs over the lifespan of a drilling project.

Broad - Spectrum Applicability

PDMs demonstrate remarkable versatility across a wide spectrum of drilling applications. In the oil and gas industry, they are suitable for vertical, horizontal, and highly deviated directional drilling operations. Additionally, they find extensive use in other fields such as mining, where accurate and efficient drilling in hard rock formations is crucial for ore extraction; geotechnical exploration, for investigating subsurface soil and rock conditions; and water well drilling, for creating reliable water access points. Their ability to adapt to different drilling depths, formation characteristics, and operational requirements makes PDMs an indispensable tool for a diverse range of drilling projects, providing flexibility and efficiency in various drilling scenarios.

Product Uses

Oil and Gas Exploration and Production

In the oil and gas industry, PDMs play a pivotal role in directional drilling. For instance, in offshore oil fields, where the target reservoirs are often located at great depths and complex geological structures, PDMs are used to precisely control the drilling direction. They can navigate through layers of different rock formations, including shale, sandstone, and limestone, to reach the hydrocarbon - bearing zones accurately. High - torque PDMs are essential for drilling horizontal wells in tight oil and gas formations. These formations require a large amount of torque to drill through the hard, low - permeability rocks. The high - precision feature of PDMs ensures that the wellbore stays within the thin pay zones, maximizing the contact area with the reservoir and enhancing the oil and gas recovery efficiency.

Mining Operations

In mining, PDMs are widely applied in hard - rock mining. When extracting valuable minerals such as gold, copper, and diamond from deep - seated ore bodies, the drilling equipment needs to penetrate through extremely hard rock formations. High - torque PDMs can generate the necessary rotational force to drill large - diameter holes for blast - hole drilling. The high - precision aspect is crucial for ensuring that the drill holes are placed accurately, which is essential for efficient blasting operations. Precise hole placement helps in controlling the fragmentation of the ore, reducing over - break and under - break, and ultimately improving the overall mining efficiency and reducing production costs.

Geothermal Energy Development

Geothermal drilling is another significant application area for PDMs. To access the hot geothermal reservoirs, which are usually located several kilometers underground, drilling through multiple layers of rock with varying properties is required. High - torque PDMs can handle the tough drilling conditions, including drilling through hard volcanic rocks and sedimentary layers. The high - precision of PDMs is vital for positioning the wellbore correctly within the geothermal reservoir. An accurately drilled wellbore can optimize the extraction of geothermal fluids, which are used for power generation and heating purposes. Precise drilling also helps in preventing the mixing of cold water from adjacent formations, ensuring the long - term viability and efficiency of geothermal energy production.

FAQ

1. What is a Downhole Mud Motor and how does it work in directional well drilling?

A Downhole Mud Motor is a tool used in directional drilling that uses hydraulic power to rotate the drill bit at the bottom of the well. This allows for precise control and steering of the wellbore.

2. How does a High Torque Mud Motor differ from a standard mud motor?

A High Torque Mud Motor is designed to provide increased rotational force, allowing for more efficient drilling in challenging formations. This results in faster drilling speeds and improved performance in directional drilling operations.

3. What are the benefits of using a High Precision Directional Well Downhole Mud Motor?

A High Precision Directional Well Downhole Mud Motor offers greater accuracy in steering the wellbore, reducing the risk of costly errors and improving overall drilling efficiency. This can lead to faster drilling times and increased productivity.

4. How does the Downhole Mud Motor handle the keyword "大扭矩" (high torque) in directional drilling applications?

The Downhole Mud Motor is specifically designed to deliver high torque capabilities, making it well-suited for demanding directional drilling projects. Its robust construction and advanced technology ensure reliable performance in high torque environments.

5. Can the High Precision Directional Well Downhole Mud Motor be customized to meet specific drilling requirements?

Yes, the High Precision Directional Well Downhole Mud Motor can be customized to accommodate different drilling conditions and project specifications. This flexibility allows for optimal performance and efficiency in a variety of directional drilling applications.