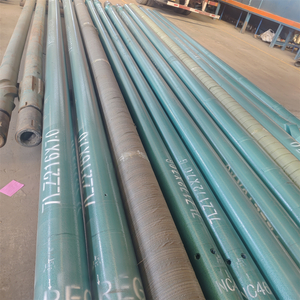

Product Introduction

Our superior PDC drill bits are high-performing drilling tools extensively utilized in industries like oil, natural gas, and geological research. They possess distinctive characteristics in terms of materials, design, versatility, durability, and production methods.

Product Advantage

1. High hardness and wear resistance: Made of high-quality polycrystalline diamond composite (PDC) material, it has extremely high hardness and wear resistance, and can maintain good cutting performance during drilling.

2. Optimized geometric design: The geometric shape of the drill bit is carefully designed, such as a reasonable cutting edge angle and shape, to improve drilling efficiency and rock debris discharge capacity.

3. Precision manufacturing process: High precision machining technology is adopted in the manufacturing process to ensure the dimensional accuracy and surface quality of the drill bit, and improve the stability and reliability of the drill bit.

4. Strong adaptability: able to adapt to different geological conditions and drilling requirements, such as soft formations, hard formations, high abrasive formations, etc.

5. Good cooling system: Effective cooling channel design ensures that the drill bit can dissipate heat well during the drilling process, extending the service life of the drill bit.

6. Strict quality control: Strict quality inspection and control are carried out during the production process to ensure that each drill bit meets top-level quality standards.

This type of PDC drill bit can improve drilling speed, reduce costs, and ensure the smooth progress of the drilling process

Product Uses

1. Oil and Gas Exploration: The Top Quality PDC Drilling Bits of Petroleum Equipment Machinery are specifically designed for oil and gas exploration purposes. These drilling bits are widely used in drilling rigs to penetrate various rock formations and extract valuable resources from the earth's crust. With their exceptional durability and cutting efficiency, these bits ensure smooth and efficient drilling operations in the harshest drilling environments.

2. Offshore Drilling: The application scenario of the Top Quality PDC Drilling Bits extends to offshore drilling operations. In the vast expanse of the ocean, these drilling bits play a crucial role in extracting oil and gas reserves beneath the seabed. Their robust construction and advanced cutting technology enable them to withstand the challenging conditions of deepwater drilling, ensuring precise and efficient drilling performance.

3. Well Construction: The Top Quality PDC Drilling Bits find extensive application in well construction projects. Whether it's drilling vertical, horizontal, or directional wells, these bits deliver exceptional performance and reliability. They are engineered to handle various drilling techniques, including rotary drilling, mud motor drilling, and underbalanced drilling. With their superior cutting capabilities, these bits facilitate the smooth and accurate construction of wells, ensuring optimal productivity and longevity.

4. Geothermal Drilling: Geothermal energy is a sustainable and renewable energy source, and the Top Quality PDC Drilling Bits are an integral part of geothermal drilling operations. These bits are designed to withstand the extreme temperatures and pressures encountered during geothermal drilling. By efficiently drilling through hard rock formations, they enable the extraction of geothermal energy, contributing to the development of clean and green energy solutions.

5. Mining and Quarrying: The Top Quality PDC Drilling Bits also find application in the mining and quarrying industry. These bits are utilized in surface and underground mining operations to extract minerals, ores, and aggregates. With their exceptional cutting efficiency and durability, they ensure high productivity and reduced downtime. From coal mining to hard rock mining, these drilling bits provide reliable performance and contribute to the extraction of valuable resources.

Product Operate Guide

1.Check the last bit for any damage, cutter dropping, or diameter reduction. Ensure there are no cemented carbide or steel hard articles at the bottom of the well after the last use of the bit. Clean the bottom of the well if necessary.

2.Inspect the drill bit cutters for abnormalities and ensure there is an O-ring in the nozzle hole. Install the nozzle as required. Clean the male or female thread and apply thread oil.

3.Install the unloader on the drill bit and lower the drill string until it contacts the male or female thread, then tighten. Finally, put the drill bit and unloader into the turntable bushing and tighten the screw thread to the recommended torque value.

FAQ

1. What is a Split PDC Drill Bit?

A Split PDC Drill Bit is a type of drilling tool used in the oil and gas industry. It is designed with a split design that allows for better drilling efficiency and improved performance.

2. How does a Split PDC Drill Bit work?

The Split PDC Drill Bit utilizes polycrystalline diamond compact (PDC) cutters to efficiently drill through rock formations. The split design of the bit helps to reduce torque and improve stability during drilling operations.

3. What are the advantages of using a Split PDC Drill Bit?

The Split PDC Drill Bit offers several advantages, including improved drilling speed, enhanced durability, reduced vibration, and increased drilling efficiency. Its split design also allows for easier maintenance and replacement of the PDC cutters.

4. What is the typical lead time for ordering a Split PDC Drill Bit?

The lead time for ordering a Split PDC Drill Bit can vary depending on factors such as quantity, customization requirements, and current demand. It is best to contact our sales team for specific lead time information.

5. How is the logistics handled for shipping Split PDC Drill Bits?

We work with reliable logistics partners to ensure smooth and efficient shipping of our Split PDC Drill Bits. Our team coordinates the logistics process, including packaging, documentation, and tracking, to ensure timely delivery to our customers.